Knowing your options and selection considerations will help you to make the right decision for long-term productivity gains.

The decision to upgrade your packaging line can benefit your operation in many ways: increased production, reduced labor and insurance costs, less liability, improved product handling and protection during transport. Or maybe you are looking to solve an operating issue that has been plaguing your line. In any case, the decisions you make during the upgrade can affect your productivity for years to come. Understanding your options, and what you need to consider during your selection, will help you to make the right decision that will bring long-term gains to your productivity.

Palletizer Selection Considerations

Robotic, conventional, hybrid? Automatic or semi-auto? High or low level? The right machine for your line will depend on many factors. Not long ago, there were major differences in cost and capabilities between conventional and robotic palletizers. Robots were best for multi-SKU applications that ran at relatively low speeds, while conventional palletizers were applicable for dedicated medium and high-speed lines. Today’s robotic palletizers can achieve higher speeds, and new control technology has given conventional units greatly increased flexibility with no downtime for changeover. Added to the mix is a new breed of hybrid palletizers that combine robotic product placement with conventional squaring devices. Finally, semi-automatic palletizers that offer a cost effective upgrade from manual palletizing for low speed lines. So, what is best for your application? First, you need to analyze your requirements:

Product Type

- Packed in a case, tray, display tray, tote or shrink-wrapped bulk packaging?

- Are shippers solidly packed, or is there headspace that can affect stacking strength?

- Is it fragile or of high value?

- Is it very heavy or lightweight?

- If bags, are they paper or poly? Are the contents settled or will bags need to be flattened for palletizing?

- How many SKUs do you palletize?

Line Layout

- Where will the palletizer be located in your plant?

- Will you feed multiple lines to the palletizer?

- How are products conveyed to the palletizer?

- How much floor space is available?

Pallet Requirements

- What are your current pallet patterns? How often will this change?

- Do you make display pallets? End-of-aisle displays? Label out loads?

- Do you make dedicated or mixed load pallets, or both?

- Do you require tier sheets, glue dots or full pallet shrink-wrap?

Speed Requirement: As the final piece on the packaging line, your line efficiency will be directly related to your palletizer’s speed and production. Mismatched speed capability and/or downtime at the palletizer can cause backups on the entire line. Make sure you are talking the same language as your supplier when discussing speed. Conventional high-level palletizers are generally rated at cases/minute, while low-level units are rated at layers/minute and robotic palletizers spec at cycles per hour.

Budget: No small consideration, your budget can help to define your selection. If your budget is tight, look for palletizers with modular designs, which allow you to add future upgrades as your budget allows.

conventional low-level palletizers require about 30% less space.

Selection Guidelines

Once you have all of your specifications and production goals in place, it’s time to talk to suppliers. Here are some basic guidelines that are applicable to palletizer selection today — keeping in mind that with advancing technology on all fronts, these guidelines may not be applicable for every situation. That is why it is important to have all of your specifications for potential suppliers, so they can evaluate your operation and help you choose the best technology for your line.

Speed: Conventional high-level palletizers are still king for high-speed lines. Conventional low-level and robotic palletizers excel on mid-range lines, and semi-auto palletizers are a solid choice as an upgrade from manual labor. When determining your required speed, it is best not to inflate your speed requirement as this can increase your machinery expenditure for speed capability you do not need. More importantly, make sure the machine you are buying has a good track record of performance and buy the speed capability you actually need.

Budget: High-level conventional palletizers have typically been more costly than low level, due to the cost of the catwalks, stairways and accessory equipment. Both high- and low-level machines typically can be programmed for new products at the operator station. Robotic palletizers usually are in line with high-level palletizers. However, their price will depend on the complexity of the application and programming required, with a simple, one-axis robot at a lower price point. Semi-automatic, low-level machines are typically one-third the cost of high-level palletizers.

Maintenance: Conventional palletizers require regular maintenance; however, the maintenance can be performed by a qualified plant mechanic. Low-level palletizers can be serviced at floor level, where high-level machines that operate at ceiling height can be more challenging to service or repair. Robotic palletizers have fewer mechanical components and extended duty cycles, but need regular lubrication and maintenance of end of arm tools (EOATs), which typically is best performed by a specially trained mechanic. However, as robots continue to enter the palletizing space, this specialty work will become mainstream.

Flexibility: All palletizing styles offer a great deal of flexibility, and most offer pallet configuration programming at the control panel. Robotic and hybrid palletizers can be fitted with a great variety of EOATs to handle a wide variety of sizes and shapes and can assemble mixed load pallets and “rainbow” loads with different products on each layer for specialized shipments to retailers and club stores.

Floor Space: This is an important concern, with floor space at a premium in many plants. Conventional high-level palletizers typically occupy the most floor space due to their construction and related catwalks and conveyors, conventional low-level palletizers require about 30% less floor space. Robotic palletizers can fit in smaller spaces, depending on the configuration and conveyor requirements. If floor space is an issue in your plant, this should be covered in your initial discussions with suppliers to determine whether a small footprint conventional palletizer or robotic palletizer will best suit your line layout.

Bulk Container Depalletizer Selection Considerations

Your depalletizing solution can literally make or break your production line, as consistent and reliable empty container feed is essential to packaging your product and meeting your production goals. Whether you are transitioning to bulk from reshipper cases or planning a new line, careful consideration of these key points will help you to avoid problems and reach your productivity goals.

Container Specifications: Bulk depalletizers run a wide range of container types including glass, plastic, steel and aluminum cans, and composite containers, in standard and many non-standard shapes and sizes. Once unloaded from the pallet, the discharge and line feed configuration will be determined by your actual container size and orientation requirements, so it is important to discuss this with your potential suppliers and provide samples for evaluation. You can rely on their expertise to help you determine the best line feeding solution: whether a simple single filer or laning device, to a row stripper that maintains container orientation, or possibly a bottle unscrambler to orient and single file small or lightweight plastic containers.

Line Speed: The industry-accepted standard is to spec your depalletizer volume at 20% higher than your filler volume. In evaluating depalletizers, it is important to look at layers/hour, not layers/minute, because different manufacturers rate their equipment by sweeps/minute and may not include cycle time between pallets. For companies that run slow speeds, a manual depalletizer may be the first step to automating this operation.

Plant Layout: Your decision between a low-level and high-level depalletizer will likely depend on your line layout. If you are planning to depalletize at the receiving dock and transport containers overhead to the production line, a high-level depalletizer is a solid choice. However, low-level depalletizers can also discharge containers at ceiling height so this is best discussed with potential suppliers. If your depalletizer will be positioned before the bottle cleaner, a low-level machine with line elevation discharge will save you the expense of overhead conveyor and lowerator that would be required with a high-level machine.

Budget: The purchase price and installation costs are typically higher for high-level depalletizers, due to the platforms, catwalks and lowerator required to transport containers back to line elevation. Low-level depalletizers require less time for installation fitting to existing line conveyors.

Additional Considerations: Many companies plan machinery upgrades to reduce costs. This makes perfect sense, as reducing production costs through automation can generate increased profits. Considering that the cost of automating your depalletizing and/or palletizing operations can easily reach hundreds of thousands of dollars, it can be appealing to look for the least cost solution to realize a quick payback. However, some would consider this a shortsighted approach, as the typical packaging machine has a projected operating life of 20 years. It is important to evaluate more than the original purchase price. Also factor the costs of installation, operation, training, maintenance, change-

over, upgrades/spare parts and even utilities, as all of these costs will impact your ultimate return on investment.

By Bryan Sinicrope, published in Packaging Strategies magazine

]]>Habit 1: Define Your Needs

Take control from the start by proactively evaluating your overall automation needs. Talk to your key people, including line operators and technicians, to get their views based on their valuable real-world experience. Consider your budget, timeline, and available floor space. Account for any special requirements for your product with regards to handling or storage, as well as how it will be shipped and displayed by the end user. Think about your required automation and the level of human intervention you plan to maintain. Speed is crucial — in specifying secondary packaging machinery, speed is determined by the maximum speed of your cartoner or filler, with at least a 10-15% cushion for unplanned production events. Plan for near-future upgrades, but be realistic, as faster equipment typically comes with a higher price tag. Evaluate your current product lineup and any anticipated changes to ensure your equipment is flexible enough to handle these demands. Most equipment has a good degree of flexibility, but if you anticipate major changes, you should discuss this with prospective suppliers.

Habit 2: Choose the Right Partner

Automating your packaging line is not a one and done deal. As you will be in a continued partnership, finding the right supplier is the cornerstone of your packaging line’s success. To narrow the field, do your research in industry forums and trade publications, and talk to people in your industry. Check their financial stability and after-sales support. Ask potential suppliers for references and talk to these customers about their experiences. These insights, good and bad, can help you find a vendor that you can trust.

Habit 3: Think About Ongoing Costs

Look past the machinery purchase price and consider the long-term costs of your packaging line including maintenance, parts and service. While an attractive purchase price is tempting, focus on the long-term value of your machinery investment. Quality equipment paired with robust support can enhance reliability, uptime, and efficiency. Invest in training for your staff to give them the skills they need to confidently operate and maintain your equipment. Schedule follow-up training if needed, to reinforce key concepts and consider service contracts to address any issues. Plan for spare parts and establish preventive maintenance practices to avoid unplanned downtime. Remote troubleshooting and repair options are available on many packaging systems giving you a direct connection to your OEM’s service department to quickly resolve any issues that may arise.

Habit 4: Build a Strategic Partnership

Consider your supplier as a partner. Think long-term when looking for solutions and stay flexible…don't fall into the trap of solely focusing on a specific technology or finding the cheapest option. Find what best fits your goals and production needs and customize where it makes sense. With a close relationship with your supplier, leverage their experience to create solutions that meet your individual requirements.

Habit 5: Tap into Expertise

Open communication with your chosen supplier is key to a successful packaging investment. Listen and learn from their sales team to understand their technology, best practices, and applications. Ask about their past projects that apply to your industry and if possible, visit a customer’s plant, where you can get a first-hand view of the machinery and talk to the end users. Be open with your supplier about your needs; provide more than just your specifications. Discuss your goals, ongoing challenges, any issues with other technology, potential line layout conflicts. With this full picture, your supplier can help you avoid problems and make sure your machines are the right fit for your production situation.

Habit 6: Work Together

By combining the strengths of your team with that of your supplier’s, you create a collaborative environment that results in a competitive, goal-aligned packaging process. Multiple viewpoints and conversations are extremely beneficial in the long term, but it is also important to designate a key contact at your company and your supplier. This simple step can help keep the teams on task for all post-order actions, eliminating potential miscommunication and ensuring that there are no unfulfilled promises on either side.

Habit 7: Keep Improving

Investing in packaging equipment is an ongoing journey rather than just a one-time event, especially as your needs evolve. Consider modular machinery that can be easily reworked at a lower cost if you anticipate changes, such as adding a product line or altering product packaging. With today's rapidly advancing technology, having a supplier that efficiently provides control and software updates is essential. Look for remote troubleshooting and repair options to connect directly with your OEM’s service department and quickly resolve any issues. By continuously seeking ways to improve your operations, you ensure that your packaging line remains competitive and efficient, keeping your company adaptable to evolving market dynamics.'

Conclusion

By enacting these seven habits, you can ensure that you are making a smart packaging investment that will meet your needs and exceed your initial expectations. Remember, your packaging machinery supplier is a partner in this journey towards improved productivity. Choose wisely and you’ll be on the right path to reach your automation goals.For more tips on buying packaging equipment, inquire about A-B-C’s full purchasing checklist here.

A Final Word

Taking the time to analyze your needs and identifying exactly what suits your requirements can pay dividends, as a good quality, well-maintained machine can provide reliable service for many years. We hope that the information in this article will help you achieve that goal. At A-B-C, we build hardworking packaging machines that stand the test of time, supported by our comprehensive service, parts and support for the life of your equipment. With over seven decades of serving the industry, we have earned many loyal customers, and repeat business is the cornerstone of our success. When it comes to packaging machines, we know the business. We would appreciate the opportunity to earn yours.

Utilize our user-friendly RFQ tool for tailored solutions, to streamline the process of defining your requirements. With just a few clicks on our website, you can input your specifications and receive expert recommendations from our seasoned team of packaging specialists. With customizable solutions tailored to your specific needs, seamless integration, and ongoing support, A-B-C is your trusted partner in packaging, committed to maximizing your productivity and success.

A-B-C Packaging Machine Corporation is in no way connected to Stephen or Sean Covey or their estate. This article is in no way endorsed by “The 7 Habits of Highly Effective People” or the Franklin Covey team.

]]>Today's smart Depalletizers and Palletizers are up to the Challenge.

As packagers embrace the Industrial Internet of Things (IIoT) to improve their processes and productivity, there have been bumps in the road to success. In a recent survey of consumer packaged goods companies (CPGs) by PMMI (Packaging Machinery Manufacturers’ Institute), respondents had some strong opinions how original equipment manufacturers (OEMs) can help them achieve overall equipment effectiveness. With goals of maximizing productivity and ensuring product quality while reducing production costs, CPGs said control technology was a top priority–and they think OEMs can do better.

Packagers want machines that are easy to set up and control. They want real-time operating data and historical trends available to evaluate OEE (Overall Equipment Effectiveness), and supported remote connectivity with their OEMs to minimize downtime. They want reliable technology, equipped with monitors to ensure machine health, and simple diagnostics to minimize unplanned downtime. These requests are not luxuries, but necessities for manufacturers to remain competitive in the ever-changing marketplace.

The good news is that OEMs have been building this functionality into depalletizers and palletizers for some time, making these machines some of the smartest on the packaging line. The network of smart components and sensors designed and built into these machines are key to keep them operating at top performance, preventing unplanned downtime, and providing the data that is essential for obtaining top productivity in the day-to-day operation. These systems efficiently protect products, minimize waste, and maximize OEE on the packaging line. Furthermore, in operating these smart machines, employees are empowered to become invested in their successful production.

Optimizing product setup and changeover

Reducing downtime for product changes is one area that can significantly enhance line productivity, especially for packagers running multiple stock keeping units (SKUs). Changeover settings for depalletizers and palletizers are implemented right at the operator control panel. Product specs are programmed in the PC, so the operator simply selects the desired product. If manual adjustments are required for conveyor or pallet size changes, the required actions are typically a part of the product setup shown on screen. They are shown as action-confirmation steps that the operator completes through the touchscreen sequence. Also available are automatic changeover packages with motorized adjusts that are activated with the new product selection. Pallet building software is typically included in standard palletizer models allowing packagers to quickly implement new product and/or pallet configurations from the factory floor. Depalletizing is similarly simplified with most machines able to unload multiple SKU’s interchangeably, often with no setting change at the control station for quick transition between products. This functionality can help packagers reduce their capital investment by feeding multiple packaging lines from one depalletizer.

Smart components to avoid unplanned downtime

Both depalletizers and palletizers and their close-linked conveyors utilize a variety of motors, variable frequency drives, and pneumatic actuators plus a battery of sensors that monitor virtually every aspect of operation, as well as safety devices. The control systems bring together all the data from these individual elements to ensure that each is operating consistently to ensure synchronized operation. For machine functions that are controlled by pneumatics, such as layer squaring and slipsheet removal in depalletizing and product positioning/layer squaring in palletizing, smart pneumatics are key to maintaining top performance. Compared to prior pneumatic technology that could slowly fail over time, these new devices monitor vacuum pressure, air flow and actuation speeds, and precisely pinpoint any device that is not performing at full capacity.

Motor sensors work similarly, sending signals to the control station with any deviation from accepted operation. By monitoring components with a known cycle life, operators have the data they need to determine if preventive maintenance is needed. These smart components and sensors continuously monitor operation, and deviations or faults are flagged at the operator panel and factory automation center, alerting staff to take proactive action. The device that is underperforming is pinpointed, eliminating downtime to troubleshoot and detect the problem. The ability to take action when issues are first detected can prevent larger problems and unplanned downtime.

Profitable maintenance efficiency and laser-focused diagnostics

These smart machines reduce downtime for predictive maintenance as the scheduled actions and required procedures are communicated to the operator through the control panel. When maintenance is due, the operator is alerted and can easily access the required actions. Inexperienced operators can view step-by-step instructions on completing these tasks. For example, many manufacturers furnish their equipment with self-lubricating bearings, however, there are some areas that will need lubrication such as metal to bearing connections and chain drives.

Efficient service with remote diagnostics

Not only has open connectivity changed the way packagers analyze machine performance and address machine maintenance, it has also opened the door to faster, more efficient service calls. Using point-to point communications technology, such as a secure I-O link through VPN, an OEM service tech can remotely visualize the performance of individual components and sensors, troubleshoot issues and get the problem resolved without the expense and time required for an in-person service call. Security for remote connectivity must be built into both devices that use the IIoT, upper-level applications that accept data from them, and remote access applications. For this, packagers can rely on automation providers to help design security architecture that will protect their network throughout the plant and enable secure connectivity to trusted OEMs.

Depalletizers and palletizers have long been important automation that can significantly improve packaging line productivity. The smart machines on the market today have the potential to greatly increase the power of these packaging technologies.

]]>The Best Options and Methods for Modern Winery Packaging ~ By Alyssa L. Ochs

Many people view packaging as a functional and practical aspect of the wine business. Still, it is also an opportunity to get creative and help your wines stand out from the competition. These days, there are many different ways to package wine for consumption, especially if you’re looking to go eco-friendly, be innovative or uniquely build your brand. In this article, we are looking at the importance of modern wine packaging, as well as the most significant considerations to keep in mind and new ideas to possibly add to your current business strategy.

Types of Wine Packaging

There are many different options for packaging wine, so many wineries choose a combination of methods to save money, entice customers or preserve the best quality. There are various sizes and shapes of wine bottles to consider, as well as wine barrels and wine closures, such as natural and synthetic corks, bar toppers and screwtops. Wineries use other packaging products, such as shrink wrap, Tetra Paks, Styrofoam, cartons, labels and pallets. Miscellaneous packaging supplies that wineries may need include tape, cushioning, newsprint and mailing tubes.

Beyond these basics, there are bag-in-box wine packaging products, paper wine bottle bags, bottle carriers and sampler gift boxes as packaging options. Molded fiber shippers and case pack trays can accommodate different bottle sizes, shapes and quantities. Foam shippers come in stand-up, lay-down, and large format options, while airline totes are good six-bottle options. To provide customers with a unique and personalized experience, it may also be worth looking into custom-printed wine totes, custom wooded presentation boxes and custom printed bags with tissue paper.

Machinery Used to Package

Wine In addition to all of these miscellaneous supplies useful for packaging wine, there are also machines available to help automate the process and increase efficiency. There are pros and cons to using automatic vs. manual means of packaging, but something to remember is that you may be able to either buy or lease packaging machinery based on your needs.

Types of machines used for packaging are case sealer machines, palletizers, automatic stretch wrappers, conveyors, case erectors, sealers and inkjet printers that print directly onto boxes. When shopping for wine packaging machinery, it is also beneficial to choose suppliers with factory-trained technicians, service contracts and a full line of replacement parts for future repair needs.

One company specializing in winery packaging is A-B-C Packaging Machine Corporation in Tarpon Springs, Florida. This company supplies packers, case sealers and palletizers for end-of-line wine packaging and has several options available to wineries.

Bryan Sinicrope, the VP of marketing and integrator sales, told The Grapevine Magazine, “From our perspective as a secondary packaging machine supplier, we are seeing an increased interest in automation from wineries of all sizes. Traditionally it was difficult for smaller wineries to justify the capital equipment expenditures to upgrade, but the current emphasis on ergonomics and worker safety, combined with labor shortages, has changed this perspective. There are multiple options for upgrading end-of-line packaging, including robotics and semi-automatic machines that have a lower cost of entry.”

Sinicrope also said that many wineries are looking for more flexibility in their packaging lines to serve new market segments.

“We are having requests for machinery that easily accommodates different package styles, such as small bottles, cartons and cans, as well as multiple secondary packages, including display cases and trays, in addition to traditional packaging.”

Sinicrope said that A-B-C Packaging stands out in the industry for wine packaging because its equipment ensures reliable performance and low maintenance, which reduces the cost of ownership. He also said that A-B-C’s machines have great flexibility and quick changeover and that the customized solutions they offer from the standard line of equipment keep costs down and minimize delivery time.

Product Recommendations and Highlights

Sinicrope from A-B-C- Packaging told The Grapevine Magazine that for bottled wine, his company generally uses robotic and pick-and-place machines.

“For pouch-packaged or cartoned wine, our robot packer provides maximum flexibility to pack into cases or trays, with a servo-powered product feed, gentle robotic packing and quick changeover at the operator station,” he said. “We also offer a semi-automatic carton packer for smaller operations that package wine in cartons, at speeds up to 10 cases per minute.”

A-B-C Packaging offers case sealing machines for a range of speeds to seal the top case flaps with adhesive or tape. The company provides conventional low-level, robot and semi-automatic palletizers for palletizing based on a winery’s budget, available space, flexibility requirements, speed and personal preference.

“Our low-level machines offer easy installation, and the floor-level control and maintenance keep operating costs low,” said Sinicrope. “A-B-C’s robot palletizers offer high flexibility to handle multiple product types with minimal hardware. Finally, our semi-automatic palletizers offer economy and flexibility for small wineries looking to upgrade.”

A-B-C has been supplying end-of-line packaging to the winery industry for over 50 years and understands the importance of maintaining the primary package integrity because many consumers will not select a bottle with even minor label or seal damage.

“Our decasers and depalletizers unload single-file bottles with minimum contact to eliminate potential damage that can cause failure on the bottling line or in distribution,” Sinicrope said. “Case erectors have exclusive features to ensure square cases for top performance at the packer. And all our packers are no-drop to ensure soft loading while protecting the labels and closures.”

Another company specializing in this industry is Custom Wine Packaging, a husband and wife team who have been in the corrugated box and custom packaging industry for over 30 years. They shifted their focus toward serving wineries and vineyards in 2014, starting with their home state of Texas and then branching out to reach wine businesses all across the U.S.

Garry Clark, the owner of Custom Wine Packaging, told The Grapevine Magazine, “We supply everything from shipping cartons to gift packaging and, of course, wine totes. The wine totes are commonly used for wine club pick-up or customer carry-out. These boxes usually display a winery’s logo, address, website, and other information.”

Packaging Considerations

There are a lot of questions that winery owners must ask themselves before committing to a particular packaging strategy. For example, there are questions about how many units are needed, how many variations you would like, how packaging can be an extension of your brand and if you can implement any innovations.

In terms of budget, wineries need to think about the upfront costs for design and products and potential future costs for breakage, additional fillers and other unforeseen needs. It may be beneficial to buy packaging products in bulk for production costs, storage and transportation handling. Also, wineries may benefit from getting professional artistic help with their packaging design if there isn’t a skilled person with extra time to commit on the staff.

Clark from Custom Wine Packaging said, “Wine packing is super important for the wines to make it from point A to point B without breakage. The totes are, in my opinion, a traveling billboard seen by many people, especially at parties and events. A lot of information can be printed directly on the totes.”

A consideration that Sinicrope from A-B-C Packaging pointed out was whether you choose to buy bottles in bulk or reshipper cases.

“Bulk bottles are less expensive per unit, but you will need a much larger initial investment with a depalletizer, case erector and partition inserter,” Sinicrope said. “With reshipper cases, one necks-down decaser or necks-up unpacker can unload and single-file your bottles. Do the math and then decide what is best for your winery.”

He also said that when looking at machines, consider how much automation you need.

“It can be a costly mistake to buy machinery for projected speeds or sizes that you may never utilize,” Sinicrope said. “Better to make sure the machinery you buy suits your line now and offers a reasonable degree of flexibility.”

Innovations and Advice

Both new and well-established wineries of all sizes understand how important wine packaging is for product preservation, brand awareness and positively differentiating a product. This can be accomplished with a custom logo, marketing slogan that resonates with customers or appearance that is classic, minimal or colorful. Many people choose a wine based on its packaging, so this is a great chance to show off your creativity with custom shapes, styles, themes and materials.

Lately, there has been a lot of innovation in the wine packaging industry with everything from QR codes that link to wine information to double insulation to keep the wine cool without refrigeration. Recyclable bottle designs and other types of eco-friendly packaging are trending, as well as augmented reality wine labels connected to a smartphone app for enhanced engagement. New glass shapes and textures can make your products stand out and engage the senses, such as flat wine bottles that are compact, eco-friendly, unique and very shippable. Another eco-friendly idea for wine packaging is eliminating foil seals or replacing them with seals from renewable sources. Buying shippers with high recycled content and packing in tight-pack shippers to eliminate the need for case partitions can also help a winery be more environmentally conscious.

Clark from Custom Wine Packaging said that his company developed a few solutions for shipping wine during the hot season, including cold pack shippers that have been a big hit. This product works by allowing the wine to pop the corks when it reaches a specific temperature.

“We have also come out with this year and are about to introduce our new wine sleeve shipping box that uses a sleeve instead of a pulp tray,” Clark said. “Many of the smaller wineries don’t have a lot of storage space, and this new method will help in that area. The package is a bit smaller than the commonly used box with pulp trays, and it may be cheaper for shipping.”

Clark shared, “We also have several types of gift boxes that hold a bottle of wine and a couple of wine glasses, which make great gift ideas. There is another gift box we offer that holds a wide variety of wine glasses, cheeses and whatever else the mind can run with.”

Sinicrope from A-B-C Packaging advises wineries to define their packaging goals before talking to suppliers so that they can help you find the best solution for your winery.

“You can learn from your potential suppliers, as they live packaging machinery every day,” Sinicrope said. “They may offer important insights that can really help you when designing your line layout, specifying your machines and getting the most out of your packaging automation.”

]]>

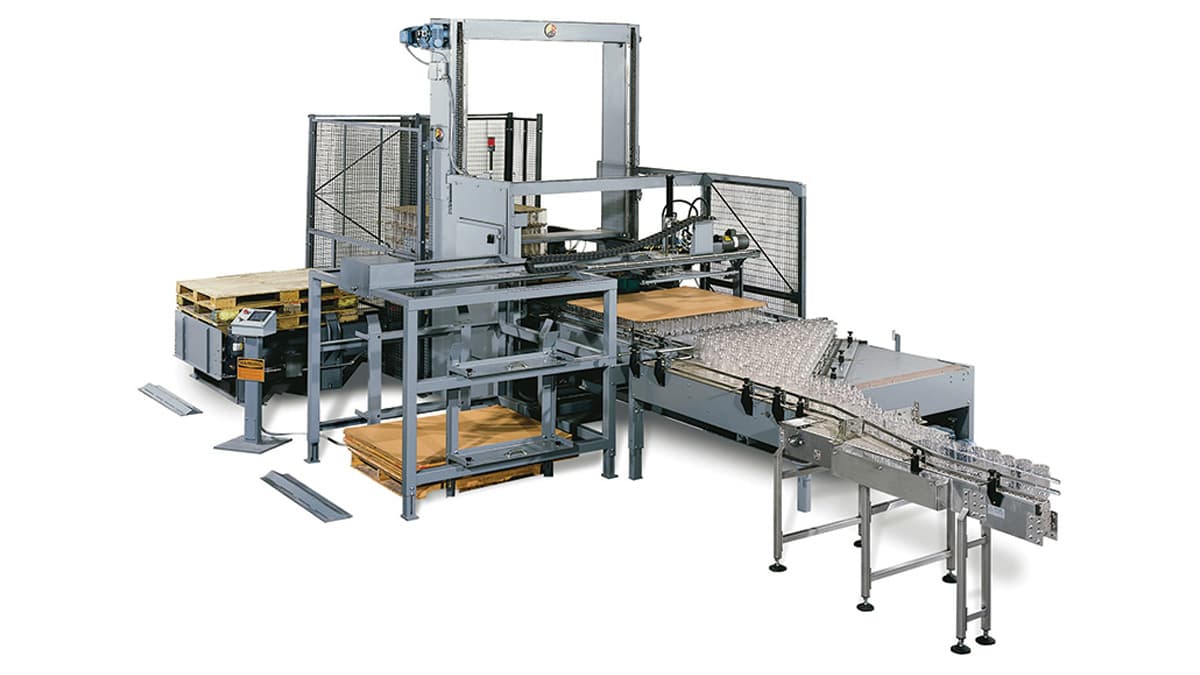

Selecting a simple packaging machine such as a case erector can be a complex process. Why? There are many factors to consider and methods to accomplish the task of setting up a corrugated KD, sealing it, and supplying it to your packaging line. Different suppliers have various reasons for their machinery designs, and it is up to you, the end-user, to determine the right machine for your application.

This guide can help you with the selection process. In our many years of building case erectors, we know the right machines can help manufacturers increase production and reduce their costs. And we’ve also seen what can go awry when the wrong machine is installed. Considering these key factors will give you the knowledge to find the best case erector for your application.

Considering an automatic case erector

for your line?

Investing in a quality case erector can streamline your packaging process, prioritize operator safety and efficiency,

and improve your overall operation. This investment can also significantly reduce long-term costs by reallocating

existing staff to higher value tasks. Additionally, with the rise of e-commerce and online shopping,

efficient shipping processes have become crucial for businesses to stay competitive.

Here are four key factors to consider to make the right decision.

Factor One: Your Corrugated

The only job of the case erector is to feed a KD, open it, fold the flaps and seal them securely. In a perfect world, this job would be simple and repeatable. But in today’s world, there are variables that you may not be able to control, so it is important that your case erector can accommodate them. If you don’t, you may be facing machine jams, misfed cases, or unsealed cases resulting in unplanned downtime and lost production. Some common culprits include:Off-spec board: Defects include misaligned slots, poor score lines, incorrect manufacturer’s joints, or over-glue on the joints that seals the KD shut

Recycled board: Can often vary in consistency. Also it can be difficult for hot melt to penetrate recycled fiber and form a secure seal

Plant conditions: Temperature, humidity, storage conditions and handling that can create warped or damaged KDs

Variations in liner board: All major corrugators inter-ship liner board to save on freight costs. Thus, cases from one supplier can have a wide range of porosity which can affect performance.What can you do?

Back in our perfect world, you’d ask your corrugated supplier for consistent board with no manufacturing defects, and control your plant to ensure proper storage and handling. But in the real world your best bet is to make sure your case erector can overcome these obstacles and keep on running. Here are some things to look for:KD feed design A KD feed that contacts the case at multiple locations is typically best at accommodating warped and band-marked cases. KD stack style is another issue. Vertical magazines require back pressure to hold the stack in place, which can cause misfeeding of cases affected by humidity. A horizontal feed magazine that lifts cases from the top of the stack eliminates back pressure requirements.

Case opening mechanism Cases with off-spec manufacturer’s joints can create problems with minor flap closing and cause sealing section jams. Ask potential suppliers how their erectors handle this potential problem.

Case squaring Out-of-spec KDs often form unsquare cases and belt drive case transfer can amplify this effect. Look for a case transfer that precisely controls the case during transfer and squares it during sealing.

Factor Two: Your Specs

Although you may know your current case erecting specs, it can be difficult or impossible to predict what you need next month or next year. How to be sure to have the capability to meet your near-future needs without costly upgrades or a new machine, and yet not “over spec” the machine you are buying today? Plus a few more observations....

What can you do?

Realistically evaluate your current needs If your line is running at 10 cases per minute, you probably don’t need expansion capability to 30 cpm unless that need is on the immediate horizon. While a high speed case erector can certainly do the job at a lower speed, high speed machine technology is more expensive and you may be paying for features that you don’t need.

Then, build in a cushion It’s good practice to purchase an erector at 10-15% more cases/minute than your line is currently running. This will give you a cushion for unplanned production events. If your plans include a line upgrade, add your near-future speed projections to this number. Having a discussion with your prospective suppliers about your needs gives you the benefit of their experience in this area.

Buy a standard model Most case erectors run a wide range of cases so it's fairly easy to find a standard model for most cases. However, if your specs are outside the norm, bring this up early in the discussion with your potential suppliers. This will help you to narrow your selection to standard machines that suit your needs. Optional equipment and custom engineering will cost more, but if that's the only option, you can discuss this with the OEM to minimize the impact.

Reduce human intervention Typically you need an attendant to load the KD magazine. A machine with a large capacity, easy-load magazine will minimize this need and related cost, and extended magazines are available. Consider a low-case warning beacon/alarm as a refill reminder to prevent case runout and loss of production.

Consider your sealing method Your sealing method will affect your cost of production, so here are some facts if you have the option to make this choice:

Tape

• Lower initial machine cost

• Higher expendable (tape) cost

• More frequent intervention to replace tape rolls

• Not optimal for high speeds

• Tape quality can affect performance (higher cost)

Hot Melt Adhesive

• Higher initial machine cost

• Lower expendable (hot melt) cost

• Hot melt unit will require maintenance

Factor Three: Your Packaging Line Operation

Downtime is required for changeover and maintenance, but there are ways to manage these activities and their related costs.

What can you do?

Analyze quick changeover claims Virtually every case erector manufacturer will tell you their machines are quick changeover. It will be up to you to decide what “quick” is in your plant. Look for no-tools changeovers to really speed up your case size changes. Also, adjusting mechanisms with position indicators can ensure precise adjustments and minimize tweaking.

If your line will require frequent changes, it may be cost-effective to look for automatic changeover. This option allows the new case size to be selected at the operator panel, which activates motors that adjust the machine to the new case size.

Make changeover training a priority The simplest task can be difficult without understanding. Most suppliers will offer training, but ask for PMMI certification for their trainers. PMMI- certified trainers will ensures that your staff have complete understanding of the equipment. Teach your plant personnel and everyone will benefit.

Buy a machine built for your requirements Slow speed lines put less stress on operating mechanisms so typically low speed case erectors are built with lighter gauge steel and simpler operating mechanisms. These features keep the costs low and are well-suited for conservative line speeds. As you go from midrange to high speed lines, the machine structure and technology will increase incrementally along with the cost. In evaluating machines, make sure the construction and components are rated for your true requirements and you will optimize your maintenance expenditures.

Talk about maintenance Of course you know your case erectors will require maintenance at some point- but better to discover how often it is needed before you buy. Talk to suppliers about their recommended maintenance schedules. Ensure that maintenance information will be readily available in a format that suits your needs, whether electronic, print, or both.

Look for maintenance-reducing features Ask suppliers if their machines have features or options such as lube banks or auto lube systems. These features can minimize maintenance and save significant time and money over the long term.

Factor Four: Hidden Costs

Hidden costs can be caused by an unexpected situation that affects your line’s productivity or a chronic issue that plagues your production line every day. Avoiding these problems will save you time, money and headaches!

What can you do?

Understand the costs of unsquare cases While poor cases will not cause most production lines to fail, these effects become more pronounced as you move down the line. Unsquare cases can cause issues with product alignment at your packer and pallet forming at your palletizer. At the end of the line, if you have unsquare or unstable pallets, your product safety can be compromised. Cases that are not formed and sealed squarely lack the stacking strength of correctly formed cases. These are good reasons to confirm that the erector you choose can reliably and consistently deliver square cases to your line.

Know the real consequences of case erector failure Jams are the most common cause of case erector downtime which can bring your production line to a standstill without notice. Through the case erecting process, there are many points where the case can jam so it is important to evaluate the design of the case erectors you are considering to be sure that cases are under full control from infeed through sealing and compression.

There are different methods of controlling the case and some work more reliably than others. So plan to discuss case handling and control with your prospective suppliers and ask for user data. If possible plan to see the machine in operation, and run a test of your cases on the machine. Taking these steps will ensure that you get the operation you expect at your line speeds and ensure the future success of your line.

Consider the costs of poor or no training We said it before, but it bears repeating...your case erector is likely one of the simplest machines on your line, so machine training may not be a priority. Yet we find that a great majority of operating issues stem from improper setup and/or adjustment, improper maintenance or sealing system issues. Use your OEM’s resources to make sure your people are well trained and it will pay many dividends over the life of your machine.

Realize the true cost of your equipment What your equipment costs goes beyond the purchase price. Factor in output yield, uptime (run ready), parts and maintenance (type and frequency) to calculate your real cost. This is termed Cost of Ownership: your actual out-of-pocket costs over the life of the machine. This evaluation will help you determine whether a low cost machine actually has a higher cost aside from the purchase price.

A Final Word

Taking the time to analyze your needs and specify an erector that suits your requirements can pay multiple dividends, as a good quality, well-maintained machine can provide reliable service for many years. We hope that this guide will help you achieve that goal. At A-B-C, we build hardworking packaging machines that stand the test of time, supported by our comprehensive service, parts and support for the life of your equipment. We're here to answer your case erecting questions and provide expert consultation, including detailed information on our case erector floor plan specifications. Call 800-237-5975, or contact us for a consultation with our packaging equipment specialists. To see case erector application videos, visit our YouTube channel.

Case erectors increase line flexibility and reduce changeover downtime

As package design has become a marketing tool to attract consumers, packagers are challenged to implement new materials, containers, and package types, and often in very short timeframes. Packaging machines that can easily adapt to new production parameters reduce the cost and time for product changeovers, providing a marketing edge.

An end-of-line packaging operation with highly flexible, separate but integrated components–case erector, robot packer, top case sealer and palletizer–offers a complete solution that readily adjusts to product changes. These machines can be reconfigured without capital expenditures for retooling that can be required to run new product styles on all-in-one erector-packer-sealers and wraparound packers.

Case erectors can erect and seal a broad range of KD sizes and styles including trays and display cases. They can be adjusted to run different size KDs in a matter of minutes. For packagers running multiple KD sizes or who change products frequently, automatic changeover can be implemented. Auto-changeover packages typically include motorized adjustments that are activated by selecting the new package dimensions at the operator station.

Square cases are critical to line productivity and product integrity

Another benefit of case erector automation is improved case quality. Case erectors are designed with features to make square cases, even if your KDs are improperly slotted, band-marked or warped from poor storage. (read more here) Case erectors are designed to accommodate KDs from recycled stock and form them into square, strong, well-sealed shippers.

Why are square cases so important? Square cases enable the packer, whether a human, robot, drop packer or place packer, to easily insert the primary packages into the case. Unsquare and poorly formed and sealed cases can cause product damage and/or lost production if they cause equipment jams.

Square cases are also basic to pallet integrity. Pallet strength, and ultimately the protection of your products, rests on the strength and unity of your pallet loads. Pallet contents can shift during transport and settle in storage, and square cases provide the structural strength to protect the products inside. Pallets built from unsquare corrugated cases have up to 30% less structural strength with the potential for failure to the detriment of the product load.

Ease of operation and maintenance

Today’s case erectors are smart machines. Most erectors on the market (and all A-B-C case erectors) have sensors that monitor functions and controllers that automate operation. They are equipped self-diagnostics that pinpoint machine issues for quick resolution. They are designed for efficient hot melt adhesive and/or tape replenishment and routine maintenance can be managed by the line operator.

Case erectors are a practical upgrade for low speed lines

When evaluating a manual line for automation opportunities, case erecting is a logical choice. Setting up and sealing corrugated cases by hand is repetitive and tedious, and the average manual case erecting speed ranges between 3-5 cases per minute. Once that speed is exceeded, it makes sense to automate. Other justifications include reduced reliance on the labor pool and improved case quality for better product protection. Low speed case erectors’ conservative price tags make them easy to justify and their compact footprints take up little space on the packaging line. Typically packagers can expect a 6-12 month return on investment with this upgrade.

What’s the future for case erectors?

Case erectors continue to be essential to end-of-line packaging automation. They are easily integrated components that enable line flexibility, improve production and deliver quality cases to the packaging line. Machines are available in a wide range of speeds from entry-level to high volume production to suit many industries and applications. Over time, case erectors will continue to evolve to offer even more features to address packagers changing requirements and deliver ever more flexibility, ease of use, and value to the production line.

- Bryan Sinicrope, VP marketing and integrator sales, A-B-C Packaging Machine Corporation, Originally appeared in Packaging Strategies magazine, updated 5/2024

]]>

Square, securely sealed cases are more important than ever, as end users and ecommerce giants set new rules for CPG compliance.

But how can you get more from your case sealing operation?

We've identified 5 key factors you can manage in selecting or upgrading your case sealing equipment.

With these under control, you can deliver consistently high quality cases and improve your case sealing line productivity.

A-B-C's production-proven features deliver superior case sealing performance:

A-B-C case sealers utilize exclusive features to address 5 important case sealing factors, giving you consistent, reliable sealing and square, well-sealed cases.

Consistent case feed is ensured whether spaced or continuous. The pacer belt infeed separates and spaces the cases precisely for flap closing and sealing.

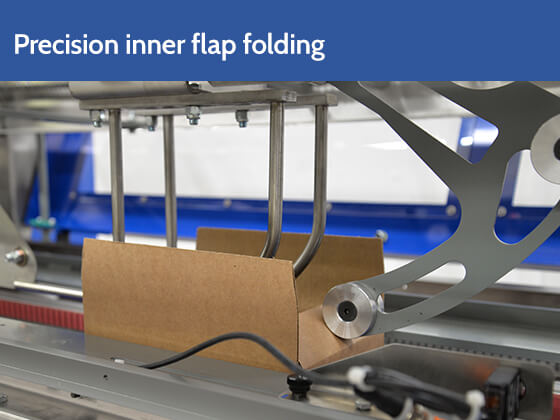

Inner flaps are closed by either a reciprocating or rotary tucker, depending on the speed and application. The robust mechanisms precisely break the scores and positively fold the inner flaps to facilitate outer flap closing.

High traction, bottom belt drive provides positive transport and control. All cases are precisely indexed through flap closing and sealing.

Outer flaps are guided closed by contoured folders while a squaring bar eliminates flap overlap. This design is proven to deliver square cases for stable palletloads.

Case flaps are compressed by flexible rollers to secure the hot melt bond. The rollers accommodate case height variations to ensure a secure seal on every case.

Their palletizing lines run 4 cases per minute, so their needs can be easily managed by a manual palletizing crew. But the company’s management was concerned about employee safety and potential for injury when stacking the layers of bulky, heavy cases. They also wanted to palletize stacks that were 92-93” tall, as this would optimize their shipping truck capacity, but this was physically impossible with a manual operation.

With ten lines to automate, they were looking for an economical solution that would upgrade their line and eliminate the potential for employee injuries. As they began their search, it was immediately apparent that they would need heavy duty palletizers that could handle the weight of the layer loads and the bulky cases and provide dependable production for the long term. They also wanted the flexibility to further increase the height of their pallet stacks, run different sizes, or upgrade to fully automatic machines to accommodate future sales and expansion. A-B-C analyzed the company’s production lines and goals, and determined that the M72SA semi-automatic palletizer would be the best solution to address the customer’s needs both immediately and in the future. The proposed solution offered the following advantages:

- No more lifting cases and related liability

The attendant simply slides cases from the infeed conveyor into the pallet pattern. The accumulation table’s roller ball construction allows easy and efficient transfer of the heavy cases into the pallet patterns. - Complete layer flexibility

As the pallet layers are arranged by the attendant, no downtime or changeover parts are needed to run different pallet configurations or even different products. When running a different case size, the palletizer automatically senses the new case height and places each layer in the correct position. - Maximum height pallets are easily built

Layers are palletized automatically after the attendant arranges them in the pattern and activates layer stacking. The palletizer was designed for their current pallet height, however it can form taller palletloads if their needs change. - Rugged workhorse machine construction

This palletizer is built for production with a heavy gauge steel frame that is welded and bolted for maximum strength. The elevator transfer table is counterweighted to minimize load stress, and designed with crossbar reinforcing beams to ensure maximum load support. It utilizes a soft start-soft stop motor drive to ensure smooth vertical load transport and motor drive longevity. - Low cost solution

The palletizer’s floor level design and rugged construction are key to reducing the palletizer’s operating costs. The electric motor drive provides precise performance and efficient operation for long term production. The pushbutton operator panel offers simple and direct control of the machine operation without the expense of sophisticated electronics. For this customer, the palletizer was an economical solution to upgrading their packaging lines and reducing liability.

Retail ready packaging (RRP) is on the mind of most packaged goods companies today. In some cases, it is a requirement for distribution in large retailers and big box stores. Yet RRP can also offer sustainability rewards in reduced material consumption.

What is retail ready packaging?

In the simplest sense, it is packaging that arrives at the end user ready for display. No corrugated cutters, no unloading individual items, no arranging products on shelves. The product is placed on the shelf right in the shipper, saving time and making restocking more efficient. In addition, retail ready packaging makes it easy for the consumer to identify your brand, select an item, and leave the remainder intact ready for the next person’s selection.

Making the transition to RRP

First and foremost, it is important that your product is shipped safely and damage-free from your plant to the end user. There are many different product variables and packaging options to consider, including perforated wraparound cases, 2-part trays, trays with top pads and shrink-wrap, and more.

Full height display cases combine economy and flexibility

Full height display cases combine full product visibility and primary package protection. They can be shrink-wrapped or not, depending on the primary product requirements. At the retail level, they provide both stocking convenience and broad on-shelf visibility for the primary package. Yet possibly the greatest advantage is the low cost of conversion to display cases utilizing your existing downstream production equipment and an A-B-C case erector.

A-B-C erectors are designed from infeed, through opening, and sealing, to run RSC cases, HSC cases, and display cases interchangeably. No change parts are required; only dimensional adjustments if the display case size is different than your other case sizes. Therefore, an A-B-C case erector can eliminate the need for a line reconfiguration requiring major capital equipment expenditures while meeting most retailers’ display requirements.

Here’s how our unique machine design accommodates display cases:

- Top of stack KD feed with dual grippers and slidebar accommodates case cutouts- no tension is required for KD feed

- Case is opened on the major bottom flap–not the sidewall

- Cases are squared by the walking beam transfer through adhesive or tape application

- Display cases are squared during tape application or adhesive compression, forming square and secure cases for smooth packing and palletizing

Whether you need the flexibility to make RSC cases and display cases to meet retail requirements, or need to run only display cases, your A-B-C erector can supply your needs, and reduce your corrugated consumption by up to 30% with strong, secure packaging that will protect your product during transport and display it proudly at the end user.

View the video to see display case and RSC erector operation

{vimeo} 343004745 |600|400{/vimeo}

We’d be happy to discuss your requirements and options, as well as other retail ready solutions.

Call 800-237-5975 or send your specifications and goals to receive a quote at the link below.

]]>A renewable resource

Corrugated is manufactured from multiple sources including timber from managed forests, reclaimed materials and fibers and recycled paper. The virgin timber utilized is typically from fast-growing pine trees that benefit the environment by absorbing carbon dioxide during the growth cycle. Many consumers recognize the benefits of paper as a natural and renewable material, which makes it a good choice from a public perspective.

Corrugated offers full life cycle accountability

According to the latest data from the EPA (2015), the most-recycled or composted products and materials in the U.S. were corrugated boxes (28.9 million tons). In addition, many people save and reuse empty corrugated boxes as they offer a good combination of strength and durability.

Recycled corrugated has a smaller environmental footprint

While the paper industry has been maligned in the past for the energy and water consumed in paper manufacture, use of recycled materials has greatly reduced this impact. Recycled paper has already been transformed by initial manufacturing processes and it is estimated that one ton of recycled paper requires 31% less energy and over 9,000 gallons less water than production from virgin fiber.

Corrugated can reduce overall packaging requirements

Whether sealed with adhesive or tape, corrugated boxes offer provide security and protection for products from the manufacturer to the end user. Corrugated cases provide superior stacking strength and protection for products throughout shipping and warehousing. Companies looking to reduce their packaging are finding that right sizing their corrugated cases or trays through packaging optimization technology can reduce the amount of primary packaging required, saving money, resources and cutting shipping costs.

Around the globe, from Amazon to Alibaba, from luxury goods retailers to Walmart, companies are seeking responsible packaging solutions. The Walmart Sustainable Packaging Playbook sets three packaging priorities:

- Optimized design

- Sourced sustainably

- Designed for recycling

Corrugated shippers can fulfill all of these requirements. While corrugated may not be the solution for every packaging need, it offers many advantages that make it a top consideration as a sustainable packaging solution.

Click to discover A-B-C packaging machines for corrugated boxes.

Click to read more from the Fibre Box Association.

]]>

Learn how our erectors are designed to keep your line operating at top productivity and see our erectors in action.

The horizontal stack-squaring magazine ensures proper KD alignment.

Your operator simply loads cases against the magazine's squaring corner. Stacks automatically index into position providing a reliable and continuous case feed.

The top feed magazine reliably indexes warped and band-marked cases.

Cases are lifted by dual floating grippers from the top of the stack, eliminating back pressure issues and ensuring reliable feed from uneven case stacks caused by warped and band-marked corrugated.

Upper and lower vacuum cups provide positive case opening.

The case is secured from below by vacuum grippers while the mechanical opening arm lowers to firmly grip and pull it open. The robust vacuum grippers deliver reliable case erecting even on cases with excess manufacturer joint adhesive that can deter opening.

The overhead grippers "over open" case flaps for smooth minor flap closing.

This design allows ample space for the minor flaps to fold inward, and eliminates the common issue of jams during flap closing when running cases with misaligned scores or off-spec manufacturer's joints.

Case-squaring transfer for accurate sealing.

The better the case going in the sealing section, the better the product coming out. Our erectors maintain tight control of cases throughout the process, utilizing our "walking beam" case transfer that squares cases as they travel. For adhesive sealing, squaring lugs on the sealing ram ensure that cases are squared and sealed securely. Our erectors are designed to deliver top quality cases regardless of your real world production challenges.