Semi-Automatic Palletizer

Model 72SA

Automation for Low Volume Lines

The M72SA palletizer brings affordable automation to low volume packaging lines. This hardworking production machine is an easy upgrade from manual palletizing that delivers top reliability and efficiency to the packaging line.

A Simple Palletizing Solution for Low Volume Lines

This simple and economical palletizer makes it easy to upgrade your manual operation. You’ll have the flexibility of hand palletizing without the challenges of maintaining a manual operation. Just one operator is required to position cases on the transfer table and palletizing is automatic…layers are lifted, squared, and stacked into secure pallet stacks. This palletizer will boost your production and build strong and square pallet loads that will protect your product throughout distribution.

Although built for low volume production, the M72SA offers the same quality construction and proven production features that make A-B-C palletizers a valued addition to the packaging line. With our trademark robust design, counterweighted elevator table, variable frequency drive and layer squaring as standard features, you’ll be assured of top production and long machine life with less maintenance. With the option to upgrade to full automation, this palletizer will provide future-proof production on your packaging line.

Key Features That Benefit Your Production

All production at floor level reduces cost of operation

This palletizer replaces the tiresome task of manual palletizing, reducing costs and ensuring a safe production environment. The operator simply transfers the product from the conveyor onto the accumulation table, then activates palletizing. The layer is automatically lifted, squared, and placed precisely on the pallet stack.

Quality built to provide top production on your packaging line

- Heavy gauge steel frame

- Counterweighted and frequency driven elevator table removes load stress from the drive motor, ensuring smooth transport and long motor life

- Stainless steel, tapered stripper plate ensures stable layer transfer

- Elevator table is supported by crossbar reinforcing beams to reduce case friction and eliminate table load stress

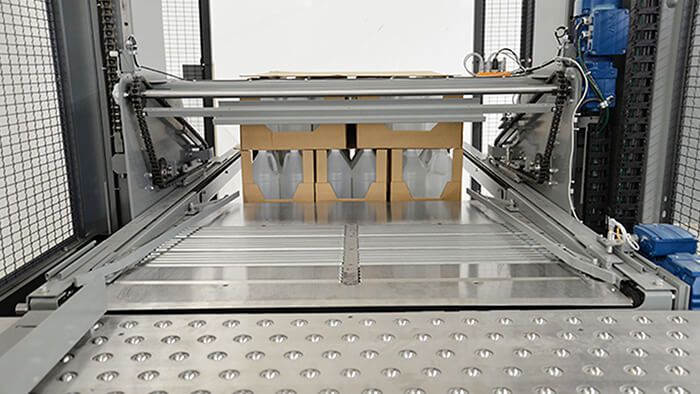

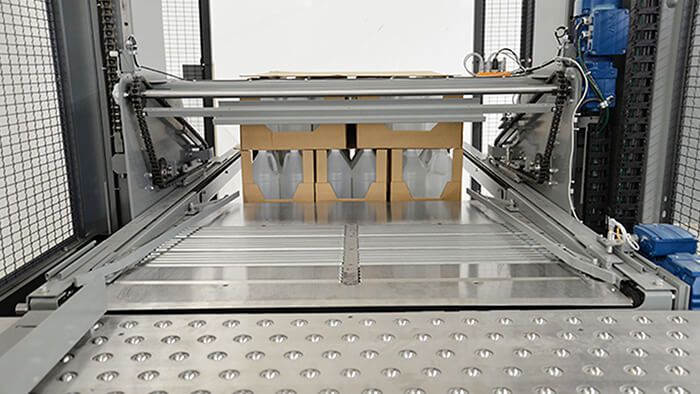

Rugged mechanical load transfer and counterweighted elevator table

Product layers are moved to the pallet by dual chain-driven transfer mechanisms that provide powerful and consistent load transfer.

The elevator table is crafted of stainless steel and reinforced to provide smooth operation for years to come. The heavy gauge stainless transfer plate is supported by crossbar reinforcing beams, reducing case friction and eliminating table load stress.

It is counterweighted to provide stable vertical transport with soft start and stop. This design maximizes drive motor performance to ensure long operating life.

A low friction roller table is available to allow easy handling of heavy and shrinkwrapped cases.

Accommodates product and layer variations to build perfect palletloads

The self-adjusting layer retainer sweep bar compensates for case load variations and ensures a positive sweep. Each layer is held firmly to retain it squarely during the deposit cycle. The sweep bar automatically centers each layer on the pallet, eliminating additional adjustments during changeover.

For some applications, a rear layer retainer plate and two side layer squaring plates are utilized to square the layer and ensure that it is centered on the pallet.

Layer squaring during layer placement builds strong and secure pallet loads for optimum product protection throughout distribution.

A system that grows with your needs

The M72SA has a modular design that allows product feed from any direction. New product and pallet configurations require no downtime or changeover…just feed the new product and the operator arranges the new pattern. If your production needs change, this semi-automatic palletizer can be modified to provide automatic operation.

Specifications, Standard Features and Options

High Performance Palletizing Features:

- Heavy steel frame construction- 7 gauge, 3/16" steel, welded and bolted for strength

- Stainless steel, reinforced elevator table with gravity design - Maximum tier weight 650 lbs.

- Counterweighted elevator table eliminates drive motor stress

- Stainless steel, tapered stripper plate for smooth load transfer

- Rear layer retainer plate and side layer squaring plates for square pallets

- Allen-Bradley PLC operation

- IEC motor starters

- Variable frequency motor drives

- High visibility guards with non-contact safety interlocks

Options:

- Low friction roller transfer table to accommodate heavy or shrinkwrapped cases

- Upgrade to fully automatic operation

- Powered pallet discharge conveyor

- CAT 3 Safety Circuits PL(d) or PL(e)

- Locking guard door switches

How Can We Help?

Do you need help finding the best palletizer for your packaging line?

Our packaging machine specialists are here to assist you in specifying the best palletizing solutions for your requirements, whether you are upgrading from manual palletizing, replacing an old palletizer or designing a new secondary packaging line. Our automatic and semi-auto palletizers suit a wide range of applications, with many options to customize your packaging equipment to your most exacting specifications. Whether your needs are simple or complex, we can help you specify the machines to meet your goals.