A-B-C Blog

Top 10 Benefits of Plastic Injection Molding for Your Business?

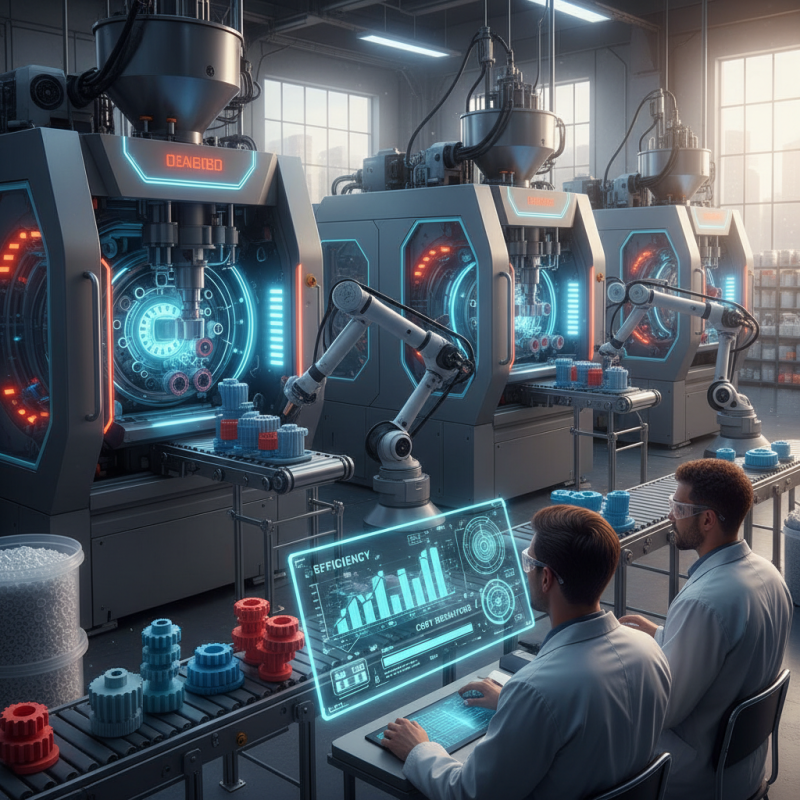

In the realm of manufacturing, the Plastic Injection Mold industry offers significant advantages. Renowned expert Dr. John Smith once stated, "Plastic injection molding is a game changer for efficiency and precision." This approach can reshape how businesses produce parts, minimize waste, and reduce costs.

One notable benefit is the ability to create complex designs with high accuracy. This process allows for versatile product development, leading to innovative solutions. However, not all companies leverage this technology effectively. Some may underestimate the initial investment required. The learning curve can be steep.

Additionally, the speed of production is impressive. Companies can produce thousands of parts quickly, satisfying market demands. Yet, the reliance on this method can lead to overproduction. Businesses must strike a balance between supply and demand. The Plastic Injection Mold process, while beneficial, requires careful planning and reflection on business goals.

Understanding Plastic Injection Molding: An Overview

Plastic injection molding is a manufacturing process that uses molten plastic poured into molds. This method is efficient, offering high-volume production capabilities. It allows businesses to create intricate designs with precision. As a result, it is important for industries that rely on accuracy.

Understanding this process reveals its complexity. The initial setup might require significant time and investment. Each mold must be carefully crafted to ensure quality. This can lead to delays if the design is not optimized from the start. Companies often face challenges when first implementing this technique, as mistakes can be costly.

Despite these hurdles, many businesses find immense value in injection molding. The material selection is vast, providing options for different needs. This can lead to innovations in product development. However, it demands continuous improvement and reflection on practices. Embracing these elements can enhance production efficiency and product quality over time.

Increased Production Efficiency Through Injection Molding Techniques

Plastic injection molding significantly enhances production efficiency. This method can create complex shapes quickly, unlike traditional techniques. Research shows that injection molding can produce parts at a speed 30% faster than machining. This rapid output directly translates to higher production rates and reduced labor costs.

Moreover, the precision in injection molding minimizes waste. A study from the Society of Plastics Engineers highlights that using injection molding can reduce material waste by up to 50%. Businesses often overlook this savings potential. The reduction in off-cuts means lower material costs, but initial investment in equipment can be high. This makes it important to analyze long-term benefits versus upfront expenses carefully.

In terms of versatility, injection molding allows for intricate designs and multiple materials. Recent trends indicate a growing demand for customized parts. Companies may struggle to adapt to this need without the right tools. While the efficiency of injection molding offers numerous advantages, evaluating the production cycles and machine maintenance is essential for sustainable success.

Cost-Effective Manufacturing: How Injection Molding Reduces Expenses

Plastic injection molding is a remarkable method for businesses seeking cost-effective manufacturing solutions. It reduces expenses in several ways. First, the process allows for mass production, which lowers the cost per unit. Larger volumes mean that fixed costs, such as machinery and setup, are spread across many products. This scaling effect is a powerful advantage for businesses.

Additionally, the ability to use less material per part is crucial. Designers can create thinner walls and complex shapes, maximizing material efficiency. This reduces waste and saves money. It’s important to note, however, that initial setup costs can be high. Businesses need to consider the trade-off between initial investment and long-term savings. Some might find themselves overestimating the benefits without proper analysis.

Moreover, timing can be a challenge when perfecting the production process. Adjustments to designs or materials may lead to delays. It is crucial for companies to remain flexible and optimize each run. While injection molding presents countless benefits, careful planning is still necessary for success. This complexity can sometimes overshadow its advantages.

Design Flexibility: Customization Opportunities in Injection Molding

Plastic injection molding offers incredible design flexibility. This method allows businesses to create complex shapes with precision. Customization options are virtually unlimited. Designers can modify dimensions, textures, and colors. This flexibility helps in meeting specific customer requirements effectively.

However, customization isn't always straightforward. Sometimes, adjustments to the design lead to production delays. It is essential to find a balance between creativity and manufacturability. Maintaining design integrity while ensuring cost-effectiveness can be a challenge. Collaboration between designers and manufacturers is crucial to address these concerns.

Moreover, the need for prototypes can complicate the process. Creating multiple iterations may result in increased costs and time. Businesses should carefully evaluate each design phase. Investing time in initial design discussions can save resources later. The journey of customization in plastic injection molding requires continuous reflection and adaptation.

Enhanced Product Quality and Consistency with Plastic Injection Molding

Plastic injection molding offers significant advantages for businesses, especially in product quality and consistency. This manufacturing method allows precise control over the injection process, leading to uniformity in dimensions and features. According to a report by the Plastics Industry Association, businesses utilizing this method report up to 30% lower defect rates compared to traditional manufacturing processes. This increased precision helps maintain brand integrity and consumer trust.

Moreover, the material selection in plastic injection molding adds to the enhancement of product quality. High-performance plastics can withstand various environmental conditions while maintaining their structural integrity. A survey conducted by the American Society for Quality found that companies leveraging advanced polymers improve their end products' durability by 25% on average. However, there are challenges in choosing the right materials and ensuring consistent output, which necessitates ongoing testing and quality checks.

While the benefits are clear, there is room for reflection. Not all plastic injection molded products meet the same quality standards. Issues may arise from equipment calibration or operator errors, potentially impacting output consistency. Businesses must invest in training and technology to minimize these risks. Balancing quality with production efficiency can be a tough line to walk, but the potential rewards are substantial.