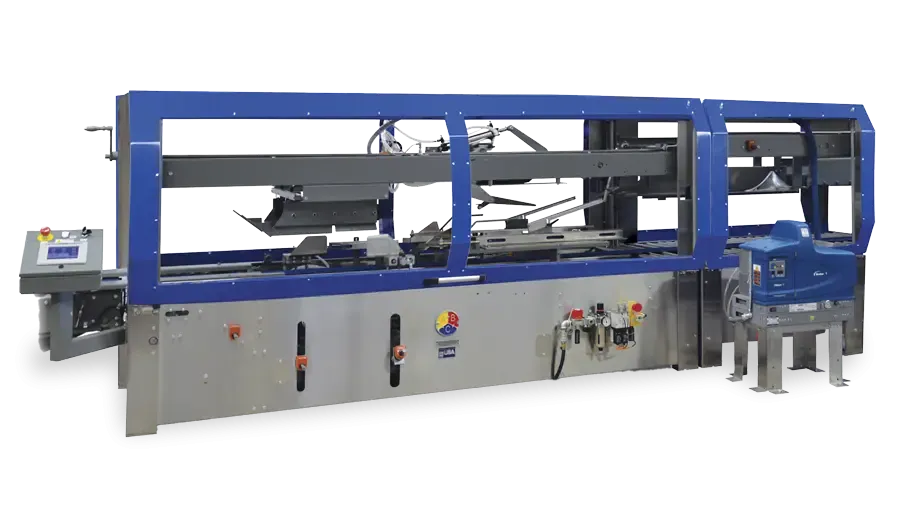

Tab Slitter / Case Sealer

Model 121

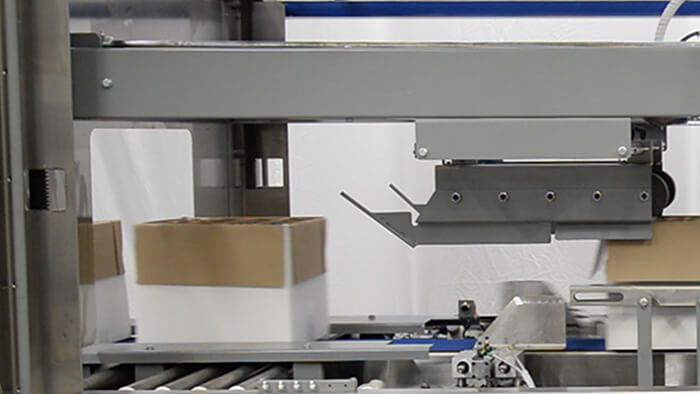

Slit Tabs, Fold Flaps, and Seal Cases, in One Compact Machine

This tab slitter and sealer brings high speed efficiency to the packaging line. Its continuous motion operation delivers top reliability, and the in-line design makes installation easy. Precision tab slitting, positive flap closing, and secure case sealing, all in one compact package.

Inline tab cutting and sealing, perfected

Accuracy and consistency are key in tablock case finishing and this machine delivers, utilizing moving tab slitters to precisely locate and slit the tabs without tearing. Unlike other systems, cases do not stop during operation. The mechanical, continuous motion drive keeps cases moving at line speed from slitting through sealing, ensuring top production.

A-B-C’s quality engineering and construction place this tablock case slitter/top sealer a cut above the competition. It’s built to provide years of reliable service and flexible to run many sizes of tablock cases to meet changing requirements. With its inline footprint, this slitter/sealer will fit into floor plans where space is limited.

For packagers who purchase bottles in tablock reshipper cases, this machine eliminates the need for manual tie-back tab cutting, increasing line speed and efficiency while reducing costs. It’s the perfect solution for packagers a range of industries from wine, distilled spirits and craft brew to household and industrial chemicals.

Key Features That Benefit Your Production

Quality construction for top performance and reliability

This slitter/ sealer's heavy gauge steel frame is welded and bolted for strength and vibration-free operation. The upper operating mechanisms are secured to the frame by a solid rack and gear system. Drive shafts are solid 1-1/4" steel.

Clear guard doors enclose the machine, keeping your line operators safe while allowing full visibility of operation. Safety interlocks stop machine operation when the doors are opened to allow full access to the machine.

For an inline machine, this slitter/sealer packs top performance into a compact footprint that ensures easy integration on the packaging line.

Product feed and line speed fluctuations are easily accommodated

The automatic metering belt infeed ensures proper spacing and control of cases, whether spaced or back to back, throughout high speed operation. High traction belting positively transfers cases from infeed through discharge.

Automatically adjust to case variations

The simple and forgiving tab slitters move inward to precisely contact the case, then lift and slit the tabs in continuous motion. The air actuated slitters smoothly contact the case body and easily accommodate case variations. This design is proven to ensure consistent tab slitting on every case.

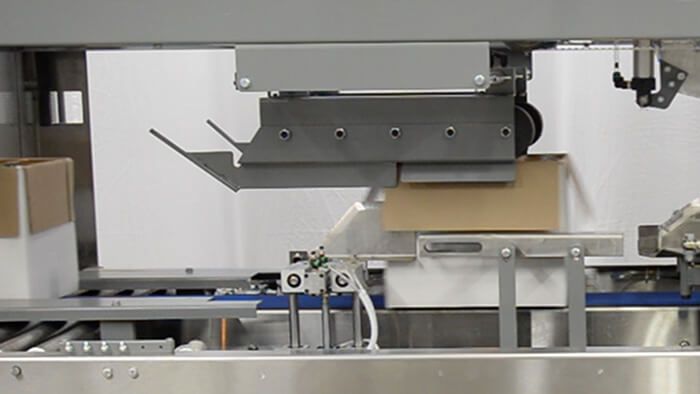

Flaps with memory resistance are handled with ease

Inner (minor) flaps are closed by a two-part system:

First, floating guides gently sweep the inner flaps upward, then they are closed by timed mechanical flap closers.

Outer (major) flap closing:

Outer flaps are guided upward by stationery guides as the inner flaps are closed. In the sealing section, A-B-C's production-proven contoured cast aluminum flap folders smoothly fold the outer flaps

A-B-C's exclusive features ensure square, well-sealed cases

The hot melt sealing model has a compression section with powered top and bottom belts backed by steel rollers that are designed to seal cases squarely. The top motorized compression belt is backed by spring-loaded rollers that ensure flap compression and sealing regardless of case variations.

The tape sealing model applies tape as cases exit flap folding and squaring. This method forms square, well-sealed cases that perform optimally in palletizing and throughout distribution.

Specifications, Standard Features and Options

Standard Features:

- Heavy steel box style frame

- Main drive motor: 1.5hp

- Inner flap lifters: (2) 1/2 hp motors

- Automatic gate release infeed feeds cases spaced or back-to-back

- CAT 3 Safety Circuits PL(d) or PL(e)

- Metering infeed

- High traction belt case drive

- Proprietary inner flap closing system

- Outer flap lifters and cast aluminum flap folders

- Adhesive model has powered compression with top and bottom motorized belts

- Flexible compression rollers provide secure adhesive seal

- Easy access tape roll for quick replenishment

- Adjustable leveling footpads (+/- 2”)

- Automatic water eliminator keeps air lines dry

- Quick changeover with rapid-adjust hand cranks

- Maintenance-free sealed bearings

- Automatic water eliminator

- Elevated beacon fault light

- Low voltage control circuit

- Clear, high visibility guards

- Locking guard door switches

How Can We Help?

Talk to our Packaging Machine Specialists

Our packaging machine specialists are here to assist you in specifying the best case sealing solutions for your requirements, whether you are upgrading from manual case sealing, replacing an old packer or designing a new secondary packaging line. Our automatic case sealers suit a wide range of applications, with many options to customize your packaging equipment to your most exacting specifications. Whether your needs are simple or complex, we can help you specify the machines to meet your goals.