Bulk Depalletizer

Model 108 Low Level

Built to meet the most demanding production requirements, this depalletizer delivers a nonstop supply of containers to the processing line.

With gentle handling features to ensure container stability and integrity, flexibility to run multiple styles interchangeably, and convenient floor level operation, this depalletizer brings unmatched value and performance to the manufacturing line.

Depalletizing Productivity Redefined

- Run glass and plastic bottles, metal cans and composite containers on one machine

- Changeover requires no tools or change parts

- Multiple features to ensure optimum container stability

- Efficient design and quality production features ensure reliable, high volume operation

These versatile machines deliver top value and productivity and prove themselves every day on packaging lines in the food, beverage, chemical, and household products industries around the world.

Key Features That Benefit Your Production

Quality built to provide top production on your packaging line

Quality construction, with proven production features and attention to detail set A-B-C depalletizers apart and ensure top performance.

- Heavy gauge channel steel frames are welded and bolted for maximum strength and durability

- Large diameter drive shafts are utilized throughout, including the container sweep and conveying systems

- Dual heavy duty industrial roller chains transport the elevator table

- Quiet and efficient electric motor drives provide reliable performance

- Elevator tables are constructed of reinforced stainless steel to minimize friction with tapered edges to ensure stable unloading

- Over 1600 pounds of counterweight contained within the twin elevator towers, to ensure smooth, accurate and vibration-free performance, even at maximum layer load

Low level depalletizing keeps production at floor level for low cost of operation

The low level design keeps operation, control, and maintenance at floor level, for maximum convenience and low cost performance. A clean, open profile ensures high visibility on the plant floor.

The floor level access points of this depalletizer keep your line personnel safely at floor level, simplify routine maintenance, and eliminate the need for costly overhead platforms. Your plant personnel can easily monitor depalletizer operation while performing other tasks.

Intelligent machine control simplifies operation, changeover and maintenance

At the touchscreen, operation is one-touch easy. You can control all functions, diagnostics, and changeover settings, and set up daily, shift, or batch runs at the menu-driven interface. Real-time operating data is available at a glance. Preventive maintenance messages automatically flag periodic or routine tasks.

Secondary layer and tier sheet are held securely during sweep-off

Before a layer of containers is transferred from the pallet to the transfer table, layer-stabilizing mechanisms square both the transferring layer and the layer below.

During layer transfer, the layer below is held securely by side mounted friction plates and the tier sheet is retained in position by four tier sheet grippers.

Multiple features work together to maintain bottle integrity and stability

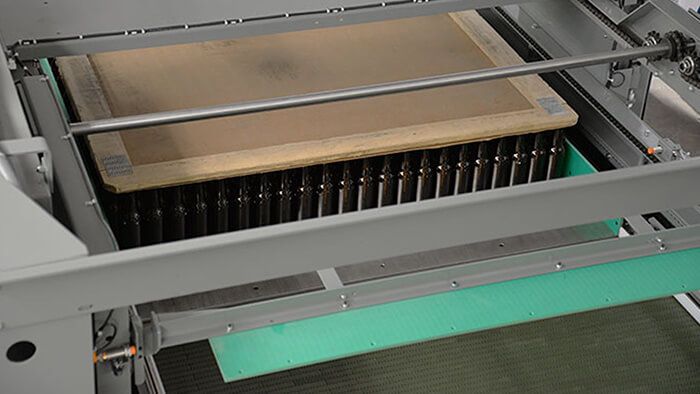

The sweep carriage that transfers containers from the pallet to the transfer table has four containment devices that ensure bottle stability; two adjustable side plates, a rear sweep bar, and front support bar.

The motorized support bar travels with the bottle load during sweepoff, preventing “sweep gap” and ensuring full containment throughout transfer. The sweep and support bars are operated by independent, frequency-controlled motors and encoders. The precision chain and sprocket sweep mechanism design is proven in hundreds of installations worldwide to provide reliable, long-term performance.

To deliver smooth and vibration-free operation

The elevator table is crafted of stainless steel and reinforced to provide smooth load transfer for years to come. The heavy gauge stainless transfer plate is supported by crossbar reinforcing beams, reducing case friction and eliminating table load stress.

The elevator table, which is guided with eight wide-faced roller bearings, is carried by heavy, high strength, industrial roller chain for exceptional performance.

A wide range of options offer enhanced automation

Many options are offered to customize automation for your needs, including empty pallet stacker, picture frame and slipsheet remover, full pallet conveyor, and container single filer. The depalletizer can be retrofitted with optional features at any time if requirements change.

Designed for your depalletizing needs today and in the future

The standard depalletizer runs plastic, glass, aluminum, steel and composite containers interchangeably, with no change parts required. It can handle loads up to 110” high.

Depalletize a range of styles and sizes, including reverse taper wine bottles, lightweight plastic bottles, jugs, F-style containers, and very small bottles and jars. Its modular design enables full adaptability for future requirements.

Specifications, Standard Features and Options

High Performance Features:

- Heavy steel frame construction- welded and bolted for strength

- Mechanical primary and secondary layer squaring before sweep-off

- Electro-mechanical dual chain-driven sweep bar

- Automatic container height detector

- Four side containment devices on sweep carriage: adjustable side plates, rear sweep bar and front stabilizer bar

- Stainless steel, reinforced transfer table with tapered stripper plate

Features for Reliable Operation:

- Counterweighted elevator table

- Adjustable guard rails on elevator table

- Programmable logic control of operation

- IEC motor starters

- Variable frequency motor drives

Reduced Maintenance Features:

- Quick disconnect non-contact sensing devices with LED indicators

- Non-contact sensors monitor machine operation

- Sealed bearings throughout

- Touchscreen control for machine jog, diagnostics, troubleshooting, changeover settings

- Elevated beacon fault light

- Safety light curtain machine guarding

- Grace Port PLC access

A-B-C's Intelligent Control:

Included in the base price of the machine, this package features:

- PLC electronics for precise control of machine operation

- Standard fault detection features

Touchscreen control panel provides:

- Set-up for daily, shift or batch runs

- Simple sequence for auto/manual functions

- Diagnostic status report screen

- Input/output machine status

Options:

- CAT 3 Safety Circuits PL(d) or PL(e)

- Multicolor machine status lighting

- Locking guard door switches

- Picture frame and slipsheet remover/ stacker

- Empty pallet stacker

- Powered full pallet feed

- Single filers

How Can We Help?

Do you need help finding the best depalletizer for your packaging line?

Our packaging machine specialists are here to assist you in specifying the best depalletizing solutions for your requirements, whether you are upgrading from manual depalletizing, replacing an old depalletizer or designing a new secondary packaging line. Our depalletizers suit a wide range of applications, with many options to customize your packaging equipment to your most exacting specifications. Whether your needs are simple or complex, we can help you specify the machines to meet your goals.