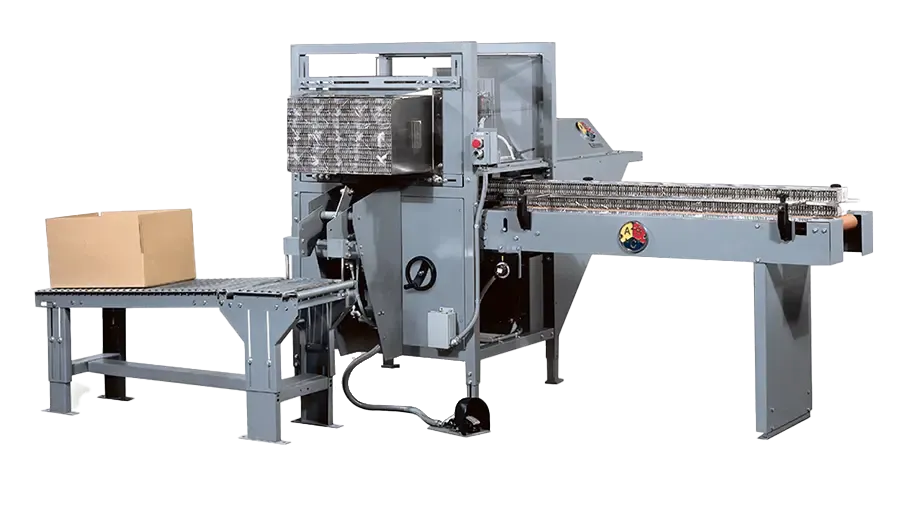

Semi-Automatic Packers

M19 and M29

These labor-saving packers are an easy upgrade from hand packing, offering compact footprints and modular designs. They are an ideal automation solution for low volume packaging lines.

Labor-saver packers for low volume lines

Step up to a semi-automatic packer to gain increased production and low-cost operation. These systems eliminate the challenges and related expense of maintaining a manual case packing crew. All accumulation and packing is automatic, the operator simply supplies cases.

Offered in two models to accommodate small and large cases, these packers are a great case packing solution bringing economy, flexibility and reliability to low-volume packaging lines.

- Pack rigid or semi-rigid containers, cartons, tubes, single or multipacks

- Pack into RSC, HSC and Display cases

- Automatic product orientation, accumulation and packing

- Top precision and accuracy unmatched by hand packing

Key Features That Benefit Your Production

Boost your packing speed to 15 cases per minute

The packer automatically handles product accumulation and packing. The operator simply opens knock-down cases and positions them on the packing funnel. They are held firmly as the product load is inserted through tapered funnels that that ensure smooth transition into the case. After packing, the full case is automatically lowered to a powered or gravity feed takeaway conveyor for sealing and palletizing.

The packer automatically matches the packing sequence to your product feed and line speed.

Packer handles products with gentle precision

Infeed conveyors and accumulation devices are engineered for gentle product handling, delivering precision and accuracy unmatched by manual packing.

Stainless steel is utilized in all areas where products contact the machine, promoting a clean product environment and ensuring smooth transfer of products with coated graphics or overwrap.

The standard models are easily adjustable to pack multiple container styles into a variety of case sizes and styles.

Only two steps: Place the case on the funnel and push the button

This packer offers simple operation with minimal operator training. The operator controls the load stroke with either pushbutton or foot pedal activation. Integrated protection includes No Case-No Load, and No Product-No Load as well as high visibility guarding that halts machine operation when opened.

Packer runs a wide range of products and package styles

Easily transition between packing RSC, HSC and Display cases to supply the needs of retail customers. Cases may have their bottom flaps unsealed or sealed.

The standard models can pack rigid and semi-rigid containers, cartons, tubes, single or multipacks.

The small footprint of these packers makes them ideal for packaging lines where floor space is an issue. The compact, all-in-one units include infeed and takeaway conveyors and can link directly to a case sealer without additional conveyor.

An optional overhead packing arm is offered to further minimize the floor space requirement.

Specifications, Standard Features and Options

Standard Features:

- Powered infeed conveyor

- Powered or gravity takeaway conveyor

- Product access door - for immediate access to accumulation chamber

- Clear, high visibility guards - electrically interlocked to stop the machine when opened

- No case, no load protection

- No product, no load protection

- Operator push buttons to activate load cycle and E-stop

Options:

- All-mechanical operation

- Adjustable funnel to accommodate extended case range

- Overhead packing arm to minimize space requirement

How Can We Help?

Do you need help finding the best packer for your packaging line?

Our packaging machine specialists are here to assist you in specifying the best packing solutions for your applications, whether you are upgrading from hand packing, replacing an old packer or designing a new secondary packaging line. Our conventional and robot packers suit a wide range of applciations, with many options to customize your packaging equipment to your requirements. Whether your needs are simple or complex, we can help you specify the machines to meet your goals.