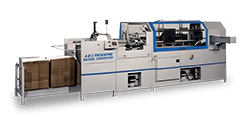

Case Erectors

Case and Tray Erectors for a Wide Range of Applications

Automatic case erectors (also called case formers and box erectors) open and seal corrugated cases with tape or hot melt adhesive and supply fully formed cases to the packaging line, ready for filling or packing. These versatile packaging machines can erect and seal a wide range of case sizes with quick changeover, increasing line efficiency and reliability.

A-B-C erectors have become a standard in many industries due to their workhorse reliability and simple operation. They feature robust tubular steel frames and powerful mechanical drives, ensuring minimal maintenance and a long machine lifespan. Exclusive features work in unison to provide continuous KD (knock-down) corrugated case feed, smooth opening, and precise transfer through sealing, consistently producing square cases for the packaging line.

Intelligent electronics simplify operation and control, allowing for seamless integration into the production line. Size adjustments for the complete case range can be quickly made in minutes, minimizing downtime. These erectors are preferred by packagers for their ability to handle less-than-perfect corrugated and valued for their proven performance on challenging packaging lines.

Our erectors are equipped with many standard features, and we offer a wide range of options to customize your equipment to your specific requirements.

|

|

|

|

|

|

| Model | 400 | 300 | 450 | 440 | 335 |

| Application | Versatile erector for a an expansive range of applications. Our best-selling erector. | For lower speeds, this erector delivers top performance and flexibility. | For high speed applications, this erector is an industry standard. | From large and oversized cases to small cases, this erector ensures top flexibility | Multipurpose case erector for Tablock, HSC, RSC and CSSC cases. Tablock bypass feature enables rapid flexibility. |

| Speed Range CPM | 400 Adhesive:10-30 400 Tape: 10-35 400HS Adhesive: 20-40 |

15-25 cpm | 20-50 cpm | 10-30 cpm | 10-35 cpm |

| Footprint | 15'-7"L 4'W 6'-3-1/2"H |

15'-7"L 4'W 6'-3-1/2"H |

16'-9-1/4"L 4'-1"W 6'-1/4"H |

19'-7"L 7'-9"W 5'-11"H |

19'"L 4'-6"W 6'-4"H |

| Sealing Styles | Hot melt adhesive Tape |

Hot melt adhesive Tape |

Hot melt adhesive | Hot melt adhesive Tape |

Hot melt adhesive |

| Case Styles | RSC HSC CSSC option |

RSC HSC |

RSC HSC |

RSC HSC |

Tablock RSC HSC CSSC |

| Case Range Min* | L 7" W 5.75" H 3" |

L 7" W 5.75" H 3" |

L 7" W 5.75" H 3" |

L 8" W 6" H 4" KD Blanks to 45"LX42"W |

L 8" W 6" H 4" |

| Case Range Max* | L 22.75" W 16" H 15" |

L 22.75" W 16" H 15" |

L 22.75" W 16" H 15" |

L 26.75" W 22" H 24" |

L 26.75" W 22" H 24" |

| Learn More | Learn More | Learn More | Learn More | Learn More | |

| *Contact A-B-C for out-of-range case requests. | |||||

How Can We Help?

Do you need help finding the best case erector for your packaging line?

Our packaging machine specialists are here to assist you in specifying the best case erector solutions for your requirements, whether you are upgrading from manual case erecting, replacing an old carton erector or designing a new secondary packaging line. Our automatic case erectors and case sealers suit a wide range of applications, with many options to customize your packaging equipment to your requirements. Call us and we will be happy to discuss your product and production needs.

How can automatic case erecting benefit your packaging line?

The current labor market poses unprecedented challenges for the manufacturing sector, particularly in recruiting and motivating workers. In the area of corrugated box erecting, the quality of your workforce can directly affect line productivity: poorly assembled cases can slow or halt packing operations and prevent the creation of stable, square pallets.

Automating this process can bring many production benefits. An automatic erector will ensure a consistent supply of well-formed cases for your line. This not only addresses the challenges posed by labor shortages but also enhances operational efficiency. Automatic forming creates smoother and more reliable manufacturing processes overall, improving productivity and reducing potential bottlenecks in your operations.

Another advantage is cost reduction. Automating your case erecting and sealing can lead to savings in labor and insurance expenses. Chances are, you’ll also reduce wasted corrugated by eliminating the source of poorly formed boxes.

The final benefit is enhanced line efficiency and product protection. We’ve said it before but it’s worth restating: A robust and accurately assembled box, facilitated by a reliable case erector, enhances performance all along the packaging line. Secure palletloads built from square, well-sealed cases provide superior protection to maintain product integrity from your packaging line to the end user.