A-B-C Blog

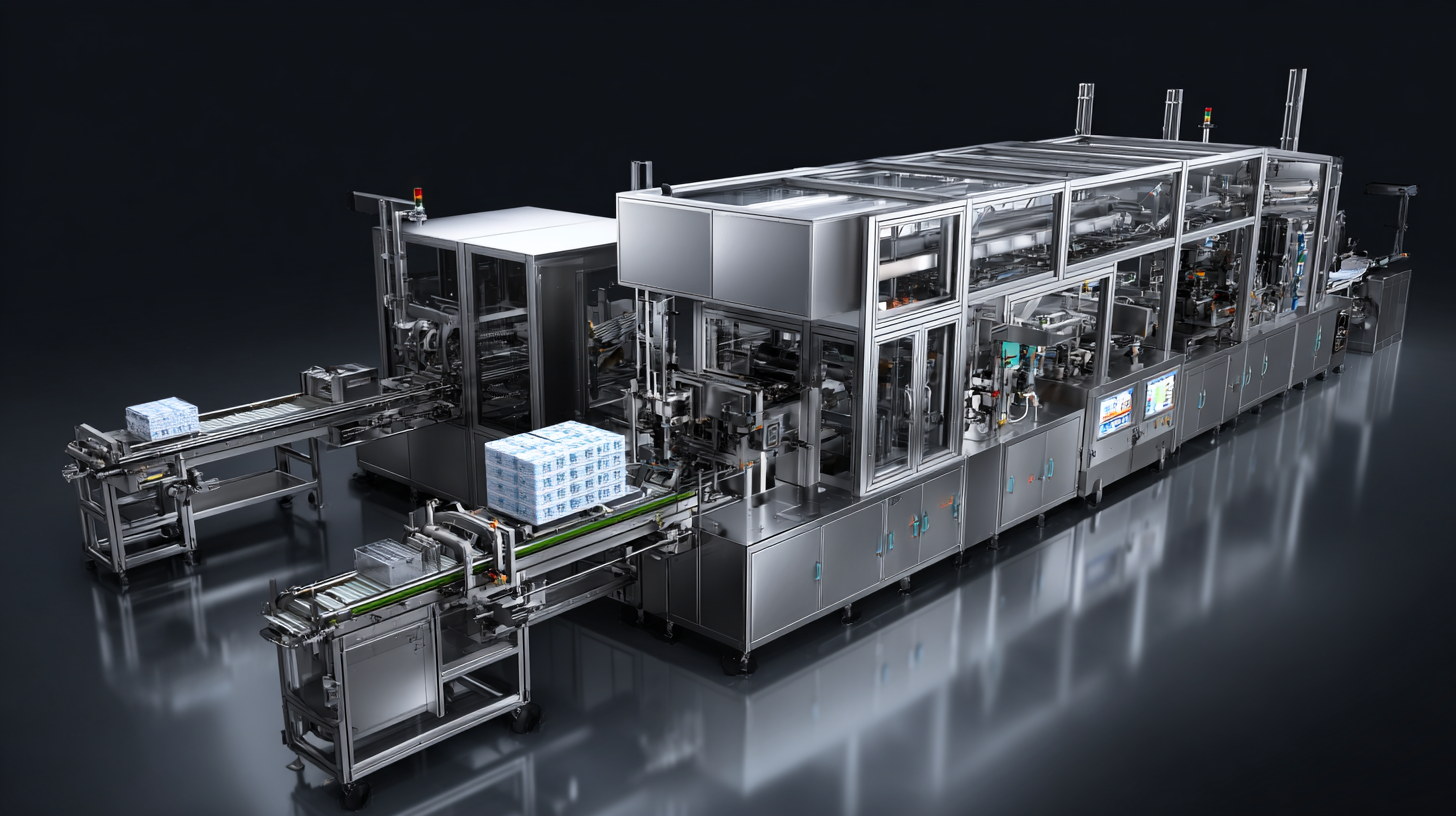

Elevating Global Standards with Best Package Machine from China

In today's rapidly evolving global marketplace, the demand for innovative and efficient packaging solutions has never been more critical. As businesses strive to meet the increasing expectations of consumers, the role of advanced Package Machines becomes paramount. China, recognized for its manufacturing prowess, is leading the charge in the development of state-of-the-art packaging technology that not only enhances productivity but also elevates global standards across various industries. This blog will delve into the intricacies of selecting the best Package Machine from China, offering a comprehensive guide on how to navigate the myriad options available, understand key specifications, and ultimately choose a machine that meets specific business needs. Join us on this journey to discover how leveraging China's expertise in packaging can transform operations and drive success in an ever-competitive landscape.

The Rise of Packaging Machinery: Transforming Global Industry Standards

The rise of Packaging 4.0 is fundamentally transforming the global packaging machinery landscape, driving improvements in efficiency, customization, and sustainability. As the world shifts towards more intelligent manufacturing processes, the packaging sector is witnessing a remarkable evolution. The global packaging machinery market is projected to grow from USD 57.74 billion in 2025 to USD 93.01 billion by 2033, reflecting a robust compound annual growth rate (CAGR) of 6.14%. This growth is largely fueled by the increasing demand for automation and advanced technologies that enhance operational efficiency.

Moreover, the explosive growth of e-commerce has significantly influenced trends in packaging solutions. The wrapping machine market alone is set to reach a valuation of USD 4.80 billion by 2033, driven by the need for flexible and efficient packaging solutions to meet consumer preferences and logistical challenges. In tandem, manufacturers are making targeted investments in digital and data capabilities, recognizing that these innovations will not only enhance production quality but also tackle the skills gap that many industries currently face. As companies navigate this dynamic environment, the integration of deep learning and machine learning techniques into supply chain management is proving essential in optimizing various operational facets, from supplier selection to inventory control.

Key Features of China's Best Packaging Machines: A Comparative Analysis

China's packaging machinery has made significant strides, positioning itself as a leader in the global market. With the packaging machinery market size projected to showcase a CAGR of over 4.5% from 2025 to 2032, reaching an estimated value of USD 69.58 Billion by 2032, China's innovations stand out in this competitive landscape. Key features of Chinese packaging machines include advanced automation, energy efficiency, and versatility, catering to various sectors such as food and beverage, pharmaceuticals, and consumer goods.

When comparing packaging machines, one must consider features like speed, precision, and adaptability to different packaging materials. The latest models integrate smart technology for real-time monitoring and maintenance, which enhances productivity and minimizes downtime. Additionally, energy-efficient designs help companies reduce their carbon footprint while lowering operational costs.

Tips for choosing the right packaging machine include evaluating the specific needs of your production line and considering future scalability. It's also crucial to look at the machine’s compatibility with existing systems and ensure that after-sales support is available for maintenance and upgrades. By focusing on these aspects, businesses can adapt to the evolving demands of the packaging industry and maintain a competitive edge.

Implementing Best Practices for Optimal Packaging Efficiency

In the ever-evolving landscape of global packaging, the emphasis on sustainable practices has never been greater. The implementation of best practices for optimal packaging efficiency is crucial for companies aiming to enhance their operations while minimizing environmental impact. A holistic approach to selecting sustainable packaging materials and strategies is essential; businesses must consider the entire lifecycle of their products and the preferences of their customers. As public awareness regarding packaging waste increases, organizations are incentivized to adapt innovative packaging solutions that not only meet eco-friendly goals but also elevate their brand image.

Emerging technologies play a pivotal role in optimizing packaging processes. With advancements in robotics and artificial intelligence, companies can feasibly enhance their packing efficiency while simultaneously pushing towards sustainability. By integrating Industry 4.0 technologies, a transformation in operational practices will streamline workflows, reduce waste, and further align packaging strategies with environmental stewardship. As organizations collectively strive towards a circular economy, there lies a unique opportunity to pioneer packaging solutions that resonate with both consumer expectations and the pressing need for environmental responsibility.

Elevating Global Standards with Best Package Machine from China - Implementing Best Practices for Optimal Packaging Efficiency

| Machine Model | Packaging Speed (units/min) | Energy Consumption (kW/h) | Operational Efficiency (%) | Maintenance Interval (days) |

|---|---|---|---|---|

| Packer 2000 | 80 | 5 | 95 | 30 |

| SpeedWrap 300 | 120 | 7 | 90 | 25 |

| FlexiPack 400 | 100 | 6 | 92 | 28 |

| EcoPack 500 | 75 | 4 | 88 | 35 |

Navigating Regulatory Standards: Ensuring Compliance in Global Markets

As global markets become increasingly interconnected, navigating regulatory standards is crucial for companies looking to succeed, particularly in industries like cosmetics and pharmaceuticals. The divergence in regulations, from strict labeling requirements to lengthy approval processes, presents both challenges and opportunities for businesses. Experts emphasize the importance of understanding local regulations to ensure compliance, as failing to do so can hinder market entry and affect brand reputation.

The landscape is further complicated by the lack of harmonization in regulations across different regions. Companies must adapt their strategies to align with varying health authority standards, especially when dealing with sensitive sectors such as medical textiles and cosmetics. Embracing compliance as a core operational strategy not only mitigates risks but also enhances competitiveness in an evolving market. Forward-thinking organizations are investing in regulatory expertise, recognizing that informed navigation of these complexities can lead to substantial growth and market expansion.

Future Trends in Packaging Machinery: Innovations from China and Beyond

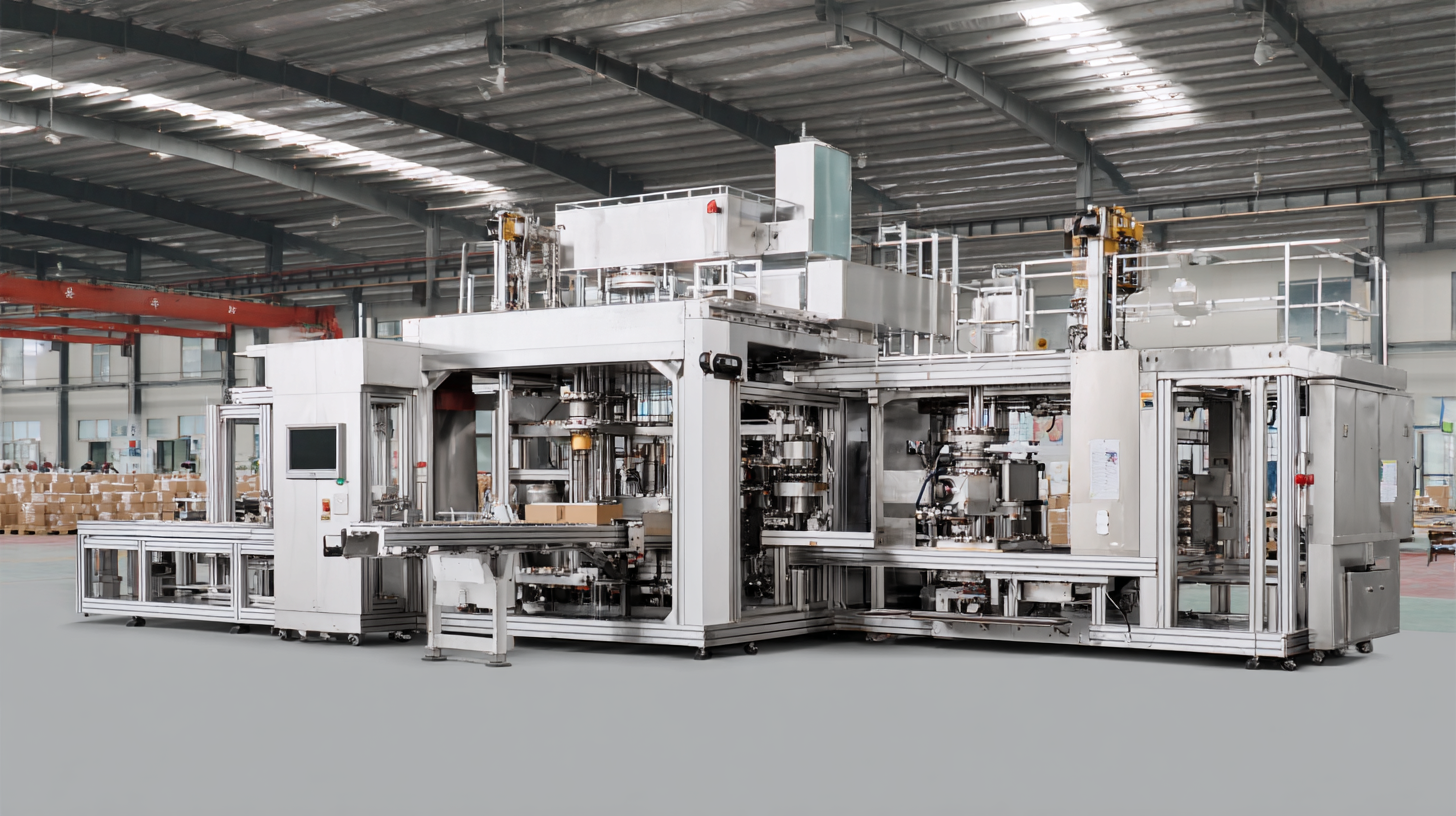

The global packaging machinery industry is undergoing a transformative phase, driven by significant innovations emerging from China and beyond. As reported, China's packaging machinery sector has seen rapid advancement, with production growth consistently surpassing expectations set during the "14th Five-Year Plan." In 2024, the added value of large-scale machinery industries in China is projected to grow by 6.0% year-on-year, highlighting the increasing competitiveness of Chinese manufacturers in this sector.

One noteworthy trend is the shift towards smart and automated solutions in packaging, which reflects a broader movement within the machinery industry. This transition is being spearheaded by advancements in technology that facilitate higher efficiency and lower operational costs. The market for packaging machinery is projected to expand, with targeted research indicating profitable investment opportunities in various sub-segments from 2025 to 2031. These innovations not only cater to domestic demands but also position Chinese brands to compete strongly on the global stage, as the pace of domestic substitution accelerates.

Amidst this evolution, policy support continues to foster industry growth, ensuring a broad and promising market outlook. Recently, events like the Shanghai International Food Processing and Packaging Machinery Exhibition have played a pivotal role in showcasing the latest advancements, gathering industry professionals to explore new collaborations and opportunities. The trajectory of China's packaging machinery sector is indeed set to revolutionize global standards as it embraces innovation and sustainability.