A-B-C Blog

Understanding the Challenges Faced by Depalletizer Machines in Modern Warehousing

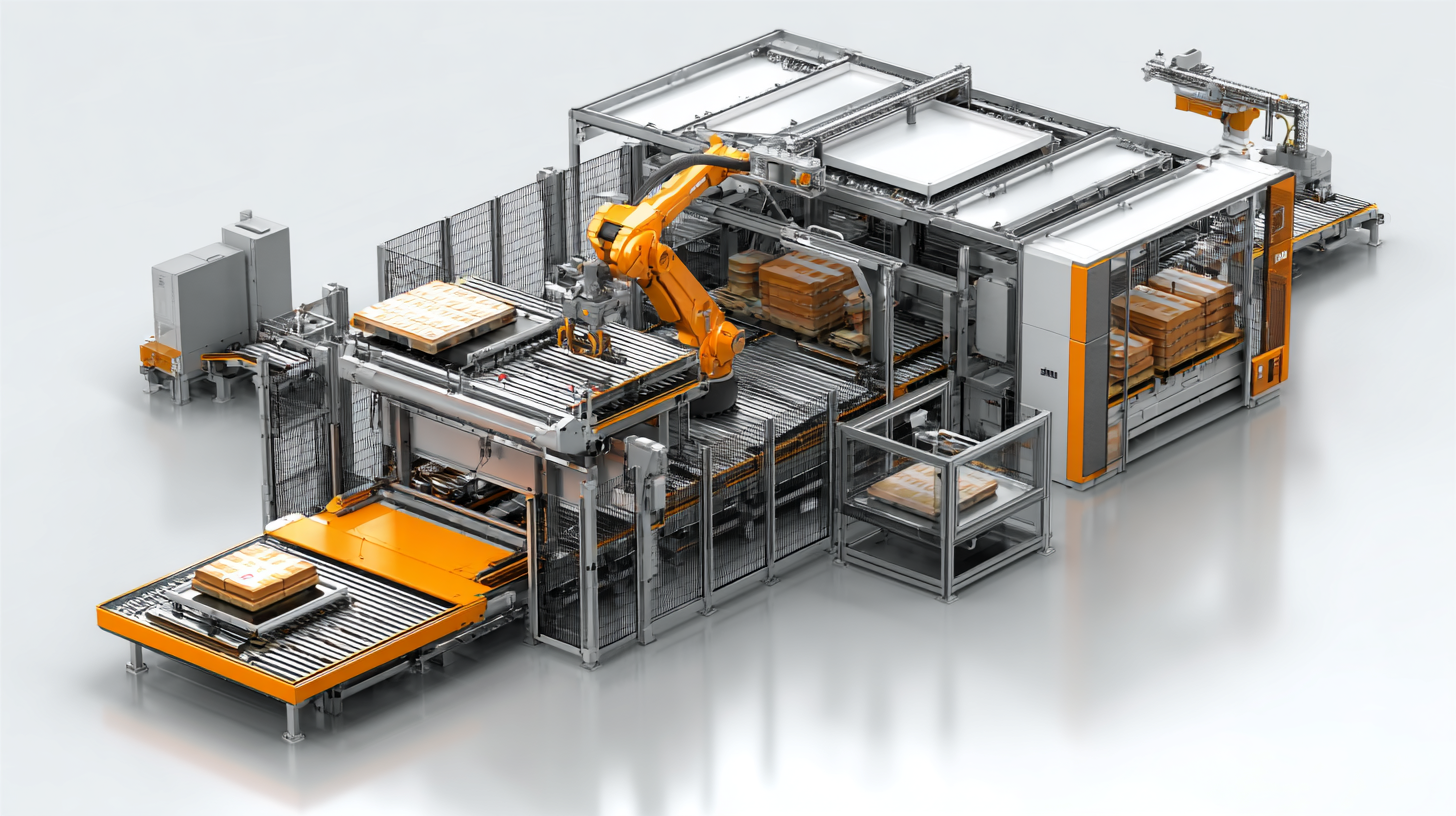

In the fast-evolving landscape of modern warehousing, the efficiency of logistics operations is greatly influenced by the performance of key machinery such as the Depalletizer Machine. According to a recent report by Mordor Intelligence, the global market for automated warehousing solutions is expected to grow at a CAGR of 14.90% from 2021 to 2026, highlighting the increasing reliance on automation to enhance operational effectiveness.

Despite their critical role in streamlining supply chain processes, depalletizers face several challenges, including variations in product types and sizes, demand for high-speed operations, and the need for seamless integration with existing systems. Understanding these challenges is essential for stakeholders aiming to optimize their warehouse operations and enhance productivity while maintaining flexibility in their logistics strategies.

Challenges in Automated Depalletizing: Data-Driven Insights

Automated depalletizing is a critical component in modern warehousing, particularly as companies strive for greater efficiency amid ongoing challenges in the supply chain. The insights from recent trends highlight that while automation presents significant advantages, it also faces numerous hurdles that businesses must navigate. Factors such as the need for skilled workers to manage and maintain advanced systems, alongside the unpredictability of supply chains, complicate the adoption of such technologies. The growing emphasis on sustainability means that depalletizer machines must integrate eco-friendly practices, which adds another layer of complexity.

Moreover, the evolving landscape of logistics technology, driven by AI, IoT, and robotics, requires continuous adaptation and innovation in automated depalletizing systems. As companies invest in smart warehousing solutions, they must ensure that their depalletizing systems can seamlessly work with other automation technologies. Understanding these challenges not only aids manufacturers in optimizing their operational processes but also prepares them for the future, where flexibility and data-driven strategies will be essential for success. Embracing these insights can lead to more effective implementation of automated solutions, ultimately driving growth and resilience in the face of uncertainty.

Understanding the Challenges Faced by Depalletizer Machines in Modern Warehousing

| Challenge | Description | Impact on Efficiency | Frequency of Occurrence | Mitigation Strategies |

|---|---|---|---|---|

| Product Variation | Diverse pallet sizes and shapes can complicate handling. | Reduces throughput by up to 25%. | High (60% of operations). | Implement flexible depalletizing solutions. |

| Mechanical Malfunctions | Breakdowns can halt operations, requiring maintenance. | Can cause complete stoppage for hours. | Medium (30% of operations). | Regular maintenance and quick-repair protocols. |

| Operator Training | Inadequate training leads to misuse of equipment. | Can reduce operational efficiency by 15%. | High (70% of new operators). | Comprehensive training programs. |

| Integration with Software | Compatibility issues with existing warehouse management systems. | Can delay order processing by up to 20%. | Medium (40% of systems). | Ensure smooth integration through testing. |

The Rising Demand for Efficiency: 70% of Warehouses Focus on Automation

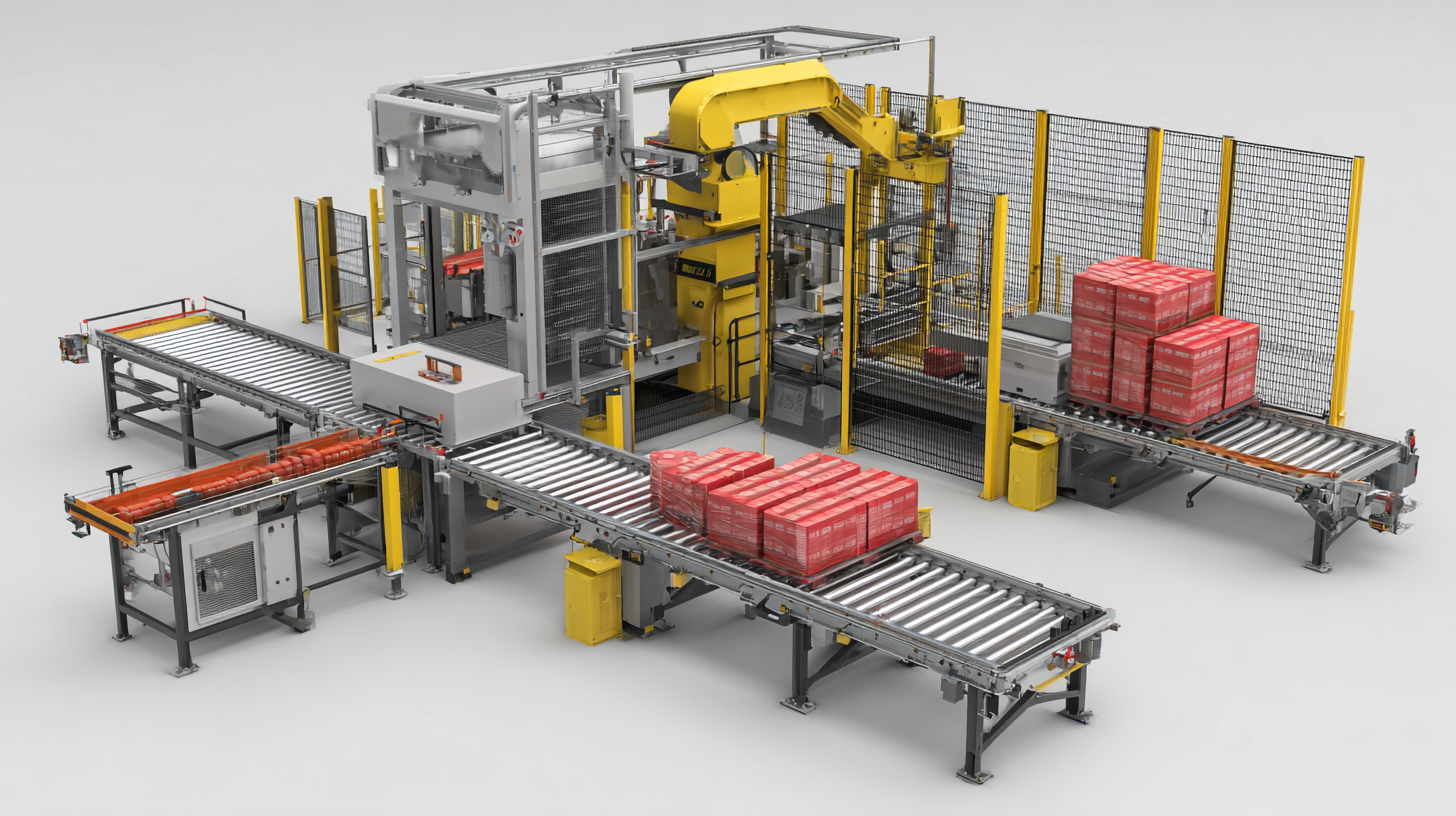

In today's fast-paced supply chain landscape, the demand for efficiency is driving an overwhelming 70% of warehouses to focus on automation. This shift is not merely a trend; it reflects the pressing need to meet increasing consumer expectations and streamline operations. According to a recent report by the Warehousing Education and Research Council (WERC), the adoption of automated systems can lead to a productivity increase of up to 30%, significantly reducing operational costs and minimizing human error.

As warehouses aim for greater efficiency, depalletizer machines are becoming critical components of automation strategies. These machines, designed to efficiently handle large volumes of products, face challenges that can hinder their performance. For example, a study by the Material Handling Industry (MHI) highlighted that 40% of warehouse operators encounter issues with machine reliability and maintenance. With the rising complexity of automated systems, ensuring that depalletizers function seamlessly is essential for sustaining warehouse productivity and maintaining the high efficiency that modern logistics demands.

Increased Downtime: How 25% of Depalletizer Machines Fail Regularly

In modern warehousing, the efficiency of depalletizer machines plays a crucial role in overall operations. However, industry reports indicate that approximately 25% of these machines experience regular failures, leading to increased downtime and operational disruptions. A study conducted by the Warehouse Automation Association highlights that unplanned downtime can cost warehouses over $1 million annually, primarily due to lost productivity and extended labor costs. This statistic underscores the critical need for robust maintenance protocols and timely upgrades to mitigate these challenges.

The reasons behind the frequent failures of depalletizer machines can be linked to various factors, including outdated technology and insufficient operator training. According to data from the Material Handling Industry (MHI), around 60% of warehouse professionals believe that their equipment lacks the necessary advancements to keep pace with the evolving demands of e-commerce. As businesses continue to adapt to high-volume order fulfillment, investing in newer, more reliable depalletizing solutions becomes essential to minimize downtime and enhance efficiency in an increasingly competitive landscape.

The Importance of Reliability: 60% of Warehouses Report Maintenance Issues

In today’s fast-paced logistics environment, reliability is paramount, with a staggering 60% of warehouses reporting maintenance issues related to their depalletizer machines. These machines, crucial for streamlining the movement of goods, face challenges that can lead to downtime and increased operational costs. According to a recent industry report, improper maintenance and outdated technology are significant contributors to these reliability concerns. As warehouses increasingly adopt automation, the pressure on depalletizer machines to perform seamlessly is higher than ever.

To enhance the reliability of depalletizers, it's essential to implement a proactive maintenance strategy. Regular inspections and timely component replacements can significantly reduce the risk of unexpected failures. Additionally, training staff on proper machine operation and troubleshooting techniques can further mitigate issues before they escalate. A report from Warehousing & Logistics International highlighted that warehouses investing in predictive maintenance technologies experienced up to a 30% reduction in machine-related downtime.

Furthermore, upgrading to newer models equipped with advanced diagnostics can provide real-time performance insights, allowing for immediate corrective actions. These innovations are not just trends but essential steps towards ensuring that depalletizers operate efficiently, maintaining the overall productivity of warehouse operations.

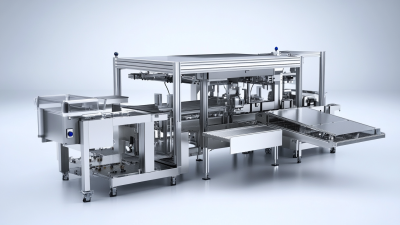

Technological Adaptation: 50% of Depalletizer Users Struggle with Software Integration

In modern warehousing, depalletizer machines play a crucial role in automating the process of unloading products from pallets. However, as highlighted by recent studies, 50% of depalletizer users face significant challenges with software integration. This struggle often stems from the rapid evolution of technology and the constant need for updates, which can lead to compatibility issues with existing systems. As warehouses aim to streamline their operations, the ability of depalletizers to communicate effectively with warehouse management systems becomes increasingly important.

Moreover, the complexity of modern software frameworks can create barriers for operators who may not have extensive technical training. Users frequently report frustrations with software interfaces that lack user-friendliness and intuitive functionality. These challenges not only hinder the efficiency of the depalletizing process but can also result in increased downtime and maintenance costs. As a solution, manufacturers must prioritize the development of more accessible software solutions, ensuring seamless integration that caters to the varying degrees of technical expertise among users.

Related Posts

-

How to Choose the Best Robotic Palletizer for Your Manufacturing Needs

-

How to Optimize Container Packaging for Maximum Efficiency and Cost Savings

-

Advantages of Using Box Taping Machines for Efficient Packaging Solutions

-

Global Quality Packaging Solutions Empowering International Trade from China

-

Selecting the Best Packing Machine Manufacturer by Analyzing Industry Standards and Innovations

-

Comprehensive Insights on Industrial Packaging Machines for Global Buyers