A-B-C Blog

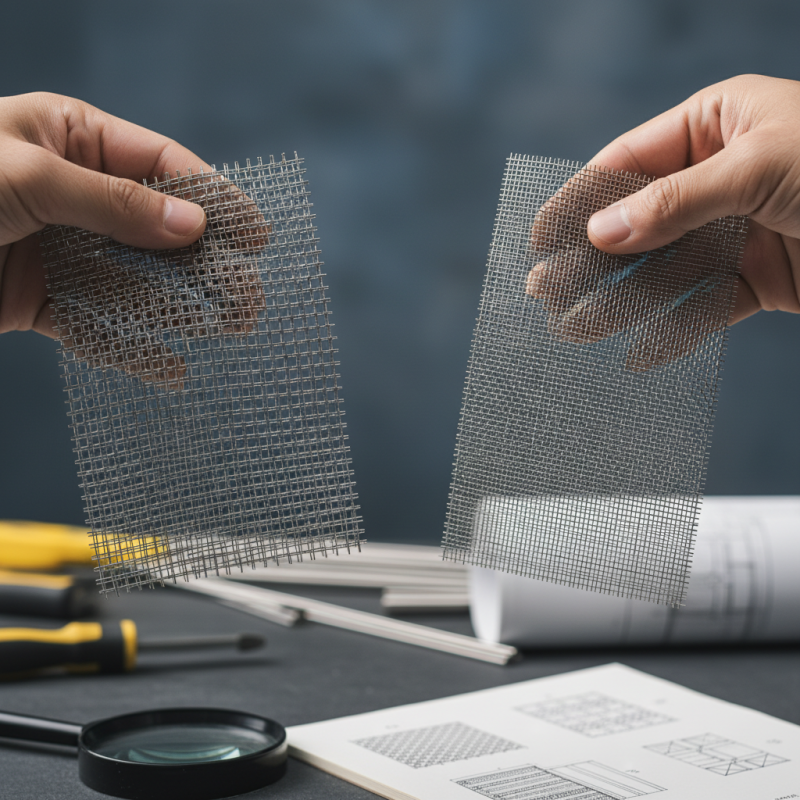

How to Choose the Right Stainless Steel Woven Wire Mesh?

Choosing the right stainless steel woven wire mesh can be challenging. There are many options available. Each type serves different purposes. It's important to understand the specifications that matter most for your project.

stainless steel woven wire mesh is durable and versatile. This material is widely used in construction, filtration, and various industrial applications. However, not all stainless steel woven wire mesh is created equal. Consider factors like wire diameter, mesh opening, and weave pattern. These elements can significantly affect performance.

Always reflect on your needs. What project requirements do you have? Will the mesh be exposed to harsh conditions? Analyzing your specific situation will lead to better choices. Ultimately, the selection process should be informed and insightful.

Types of Stainless Steel Woven Wire Mesh: An Overview

When considering stainless steel woven wire mesh, it’s important to understand the various types available. Plain weave is one of the most common types. It consists of alternating wires woven together, creating a balanced structure. This type is versatile and often used in filtration and sieving applications. However, it may not be the best choice for all situations.

Another type is twill weave, which offers a unique pattern. In this design, two wires are woven over two others. This creates a more flexible mesh, ideal for applications needing better airflow or drainage. It might not provide the rigidity some users require. The choice depends on the specific application and its demands.

Dutch weave is another option worth exploring. This type has a tight weave, with fine wires interwoven with thicker ones. It provides excellent strength but limits airflow. Users must reflect on their needs before making a decision. Each type serves different purposes, and understanding these nuances can aid in making the right selection.

Key Factors to Consider When Selecting Stainless Steel Mesh

When selecting stainless steel woven wire mesh, consider several key factors. The weave pattern can affect strength and flexibility. Common options include plain, twill, and Dutch weaves. Each serves different purposes. For example, plain weave is versatile, while Dutch weave offers higher strength.

Mesh size is crucial. Smaller openings provide fine filtration. Larger openings allow for better airflow. Think about what you need the mesh for. Is it for filtering, shielding, or structural support? This choice can influence the longevity and functionality of the mesh.

Tips: Always test samples if possible. Visualize your project and how the mesh fits into it. Also, consider the environment where the mesh will be used. Corrosive environments may require specific types of stainless steel. Reflect on these factors to avoid costly mistakes. Your choice should align with both practical needs and design aspirations.

Understanding Mesh Specifications: Wire Diameter and Open Area

Choosing the right stainless steel woven wire mesh involves understanding key specifications. Wire diameter directly impacts the strength and flexibility of the mesh. A thicker wire provides durability, while a thinner wire offers more versatility. Think about your specific needs. For heavy-duty applications, opt for larger diameters. But be cautious; too thick could hinder airflow and light passage.

Open area is another crucial factor. It refers to the percentage of space between the wires. A higher open area allows for greater fluid movement but may compromise structural integrity. Balancing these aspects is essential. Measure your requirements carefully. An incorrect open area can lead to inefficiencies. Consider the environments where the mesh will be used. For example, a fine mesh with a small open area may trap debris, while a larger one allows better flow.

Reflect on how these choices impact overall performance. Sometimes, designers overlook these details. Even slight variations in wire diameter or open area can change functionality. Testing different configurations may reveal unexpected results. Don’t rush the decision. Take time to analyze your application. The right mesh can make a significant difference in your project's success.

Applications of Stainless Steel Woven Wire Mesh in Various Industries

Stainless steel woven wire mesh plays a vital role in many industries. It is used in food processing, filtration, and construction. In the food industry, it ensures safety and hygiene. A fine mesh can filter out contaminants, maintaining food quality.

In construction, woven wire mesh is essential for reinforcement. It enhances the strength of concrete and improves durability. Architects often use it for design elements, creating visual appeal. However, not all projects require the same type of mesh. Different specifications can lead to both success and failure.

The mesh type should fit the specific application. Selecting the wrong mesh can cause complications. For instance, filters need to be precise in size. A little miscalculation can lead to inefficiency. It's critical to consider both the material and the wire diameter. This choice can impact the overall performance in unexpected ways.

Applications of Stainless Steel Woven Wire Mesh in Various Industries

Maintenance and Care for Longevity of Stainless Steel Mesh Products

Maintaining stainless steel woven wire mesh is essential for its longevity and performance. Regular cleaning can prevent the build-up of contaminants. Use mild soap and water for routine maintenance. A soft brush can help remove debris without damaging the surface. Rinse thoroughly to avoid residue that may lead to corrosion over time.

Check for signs of wear and tear regularly. Inspect welds and connections for any weaknesses. Rust can be a problem in humid environments, even for stainless steel. Ensure proper ventilation in storage areas to minimize moisture. Applying a protective coating occasionally can help, but ensure it’s compatible with stainless steel.

However, not everyone pays attention to these details. Over time, neglect can cause significant deterioration. Mesh that is not maintained properly may require costly replacements. It’s easy to overlook these tasks, but they are vital for preserving your mesh products. Taking these small steps can extend the life and functionality of your stainless steel mesh.