A-B-C Blog

How to Choose the Best Ball Screw for Sale?

Choosing the right ball screw for sale is crucial for optimal performance in numerous applications. According to a recent report by MarketsandMarkets, the global ball screw market is expected to grow significantly, reaching USD 6.6 billion by 2026. This growth indicates a rising demand for efficient linear motion solutions across various industries, including manufacturing and robotics.

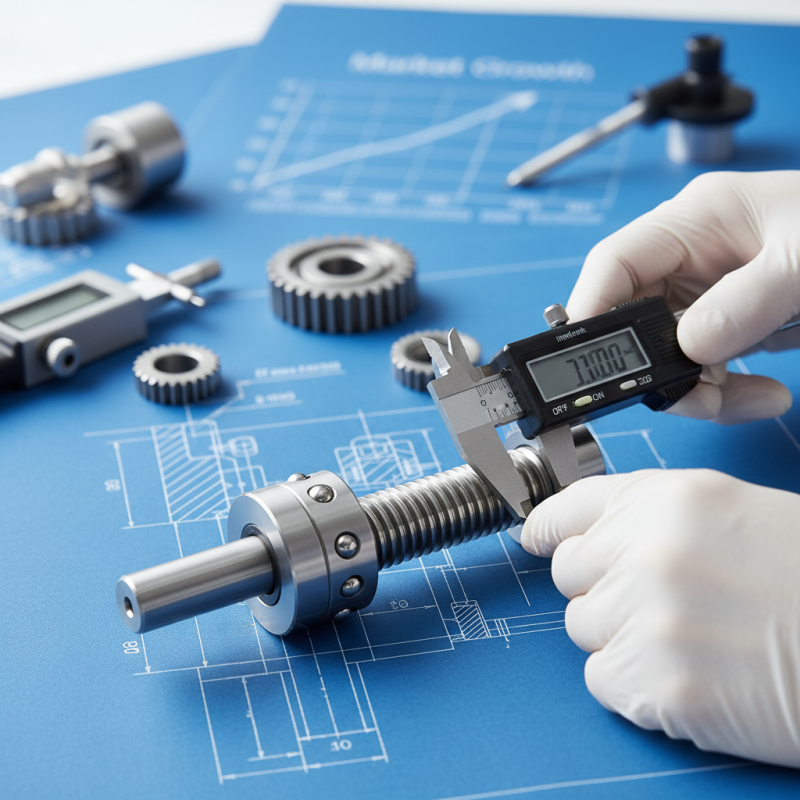

When selecting a ball screw, various factors come into play. Precision, load capacity, and installation compatibility are essential. A study by Grand View Research emphasizes that precision-engineered ball screws improve accuracy in machinery, enhancing productivity. However, many buyers underestimate these details, leading to suboptimal choices that could affect machine performance.

Understanding the specific requirements of your application is key to making the best selection. Evaluating options helps in avoiding common pitfalls. For instance, a mismatch between screw diameter and application load can cause premature failure. When searching for ball screws for sale, thorough research and application analysis are necessary to ensure long-term success and reliability in operations.

Understanding the Basics of Ball Screws and Their Applications

Ball screws are critical components in many mechanical systems. They convert rotary motion into linear motion, providing high precision and efficiency. Typically made of steel, they minimize friction through ball bearings. This results in smoother operations and longer service life. They are widely used in CNC machines, robotics, and automotive applications. Yet, understanding their specifications can be complex.

Choosing the right ball screw requires knowledge. You need to consider load capacity, diameter, and lead. Each parameter affects performance. For instance, a larger diameter can support heavier loads, but may not fit in compact spaces. Pay attention to the environment as well. Dust and moisture can impact functionality. In some cases, opting for a protective cover is necessary.

It’s common to underestimate the impact of quality. Low-cost options might seem attractive, but they may lead to rapid wear or failures. Reflect on the long-term costs versus initial savings. Spending a bit more on a durable option can save money and time later. Finding the right balance can be challenging, but vital for successful operations.

How to Choose the Best Ball Screw for Sale? - Understanding the Basics of Ball Screws and Their Applications

| Dimension (mm) | Load Capacity (N) | Lead (mm) | Speed (m/s) | Application |

|---|---|---|---|---|

| 20 x 40 | 5000 | 5 | 3 | CNC Machines |

| 25 x 50 | 7000 | 10 | 4 | 3D Printers |

| 30 x 80 | 10000 | 12 | 5 | Robotics |

| 15 x 30 | 3000 | 4 | 2 | Automated Systems |

Key Factors to Consider When Selecting a Ball Screw

When selecting a ball screw, precision is vital. Consider the load capacity first. Different applications demand different strength levels. A heavy-duty system needs robust ball screws. If you underestimate this, you might face equipment failure.

Next, assess the screw diameter and length. A larger diameter can handle more load, but also adds weight. This can impact installation and performance. Length affects travel distance and space requirements. Balancing these factors is crucial.

Don't overlook the lead, which determines speed and efficiency. A high lead allows quicker movements but can sacrifice torque. It’s a trade-off to consider. Always test and validate your choices. An oversight here can lead to higher costs down the line. Think carefully about the specifications before making a decision.

Factors Considered When Selecting a Ball Screw

Comparing Different Types of Ball Screws Available for Sale

When selecting a ball screw, it’s important to understand the various types available for sale. Ball screws mainly differ in their design and application. Rolled ball screws, which are often more cost-effective, but offer lower efficiency. On the other hand, ground ball screws provide higher precision. They might be pricier, but they deliver superior performance in demanding applications.

Another aspect to consider is the lead of the screw. It influences speed and accuracy. A larger lead allows for faster movement, but it may sacrifice precision. Smaller leads enable finer control, which can be crucial in specific tasks. Additionally, consider the material and finish. Different materials affect durability and friction. A stainless-steel option might resist corrosion better, but could be heavier.

Installation and maintenance matters too. Some ball screws require more intricate setups. This complexity can lead to mistakes during assembly. The ease of maintenance can’t be overlooked either. Frequent lubrication is a must for optimal performance, which is often neglected. Remember, every choice comes with trade-offs. Reflecting on your specific needs can help illuminate the best option for your project.

Quality Indicators: How to Evaluate Ball Screw Manufacturers

When evaluating ball screw manufacturers, quality is crucial. Look for certifications that demonstrate adherence to industry standards. These certifications ensure that the manufacturer maintains consistent quality control processes. However, not every certification guarantees the best product. Some manufacturers may prioritize paperwork over genuine quality.

Inspecting the materials used in ball screws is equally important. High-quality steel and precise machining significantly impact performance and lifespan. A manufacturer should provide detailed specifications about the materials used. If this information is lacking, it may warrant further investigation. Ask about the production process. Transparency in manufacturing shows the company has nothing to hide.

Finally, consider customer reviews. They offer real-world insight into a manufacturer's reliability. But beware of overly positive or negative reviews. It's essential to look for patterns rather than isolated opinions. A consistent issue reported by multiple customers could indicate a deeper problem. Balancing these factors may require some trial and error.

Sometimes, a manufacturer with a good reputation might not meet specific needs. Reflecting on your experiences will guide your future decisions.

Cost vs. Performance: Finding the Right Price for Your Ball Screw

When considering the cost versus performance of ball screws, it’s crucial to focus on specific needs. Ball screws are critical for applications that require precision and efficiency. According to industry reports, performance can differ significantly based on material quality and design specifications. The price may seem attractive initially, but long-term reliability often outweighs short-term savings.

Tips: Look for high load ratings. A well-rated ball screw can significantly enhance operational efficiency. Also, consider life expectancy. A ball screw with a longer lifespan can reduce costs in the long run.

The balance between cost and performance can be tricky. Sometimes, cheaper options do not deliver required accuracy. Some low-cost models may have limited capabilities. They can wear out quickly, leading to higher maintenance costs. It’s essential to evaluate the specifications thoroughly. Choose a solution that fits your machinery and workload.

Tips: Don’t ignore reviews from trusted sources. They provide insight into real-world performance. Furthermore, consider potential compatibility issues. A good fit can enhance performance and reduce unforeseen expenses.