A-B-C Blog

Ultimate Guide to Choosing the Best Bottom Case Sealer for Your Packaging Needs

In today's fast-paced packaging industry, the efficiency and reliability of sealing processes are more critical than ever. With the global packaging market projected to reach $500 billion by 2025, according to Smithers Pira, companies are increasingly turning to advanced solutions to enhance productivity.

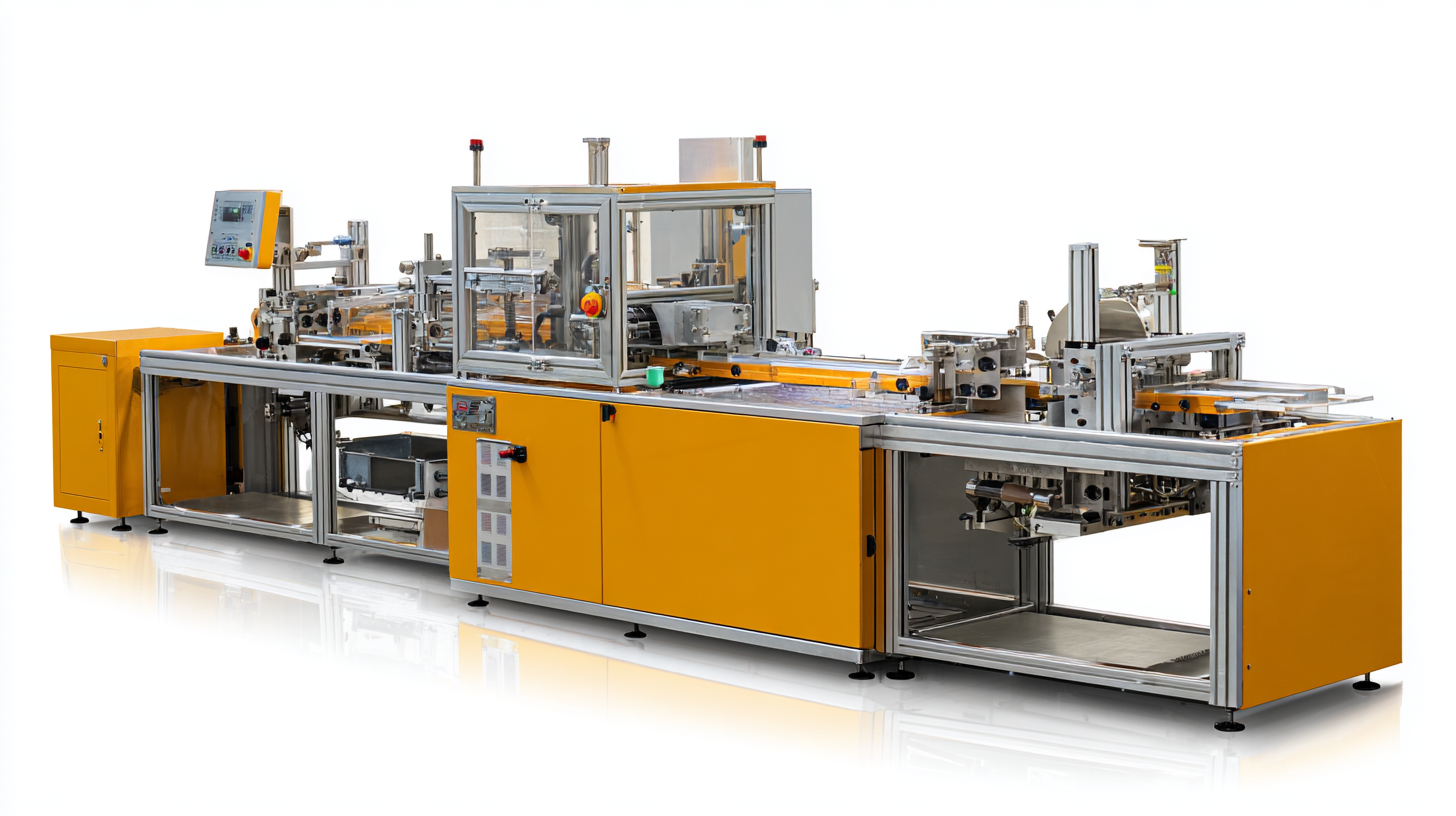

One essential component in this optimization is the Bottom Case Sealer, a vital investment for ensuring product integrity during transit. As demand for automated solutions rises—forecasted to grow by 7% annually—selecting the right Bottom Case Sealer becomes paramount. This guide aims to equip you with insights and considerations tailored to your unique packaging needs, ensuring you harness the best technology available, particularly from world-class Chinese manufacturing facilities that are renowned for their superior production capabilities.

One essential component in this optimization is the Bottom Case Sealer, a vital investment for ensuring product integrity during transit. As demand for automated solutions rises—forecasted to grow by 7% annually—selecting the right Bottom Case Sealer becomes paramount. This guide aims to equip you with insights and considerations tailored to your unique packaging needs, ensuring you harness the best technology available, particularly from world-class Chinese manufacturing facilities that are renowned for their superior production capabilities.

Understanding the Different Types of Bottom Case Sealers for Packaging

When it comes to selecting the right bottom case sealer for your packaging operation, understanding the different types available is crucial for optimizing efficiency and ensuring product integrity. There are generally three main types of bottom case sealers: manual, semi-automatic, and fully automatic. According to a report by MarketsandMarkets, the global packaging automation market is projected to grow to $82.3 billion by 2025, indicating a significant shift towards mechanized solutions. Manual sealers are ideal for smaller operations or businesses with low-volume needs, while semi-automatic sealers cater to medium-scale production, providing a balance of speed and labor efficacy.

Fully automatic bottom case sealers are increasingly favored in high-speed production environments due to their ability to operate continuously without the need for human intervention. The same MarketsandMarkets report highlights that fully automated systems can reduce labor costs by up to 30% while increasing throughput by 50%. Manufacturers need to consider these options based on their production volume and specific packaging requirements, as the right bottom case sealer not only enhances operational efficiency but also ensures consistent sealing quality, which is vital for product shelf life and consumer satisfaction.

Ultimate Guide to Choosing the Best Bottom Case Sealer for Your Packaging Needs

| Sealer Type | Key Features | Ideal Applications | Production Speed (cases/min) | Price Range ($) |

|---|---|---|---|---|

| Tape Sealer | Uses adhesive tape for sealing, adjustable for different box sizes | E-commerce, retail packaging | 10-30 | 500 - 2000 |

| Hot Melt Sealer | Uses hot melt adhesive, strong and durable seal | Food industry, bulk packaging | 20-50 | 800 - 3500 |

| Case Erector with Sealer | Automates case forming and sealing, highly efficient | High-volume production, manufacturing | 30-70 | 2000 - 7000 |

| Strapping Machine | Uses plastic or steel straps to secure packages, adjustable tension | Heavy-duty shipping, palletizing | 10-40 | 1000 - 5000 |

Key Features to Look for in a Bottom Case Sealer

When selecting a bottom case sealer for your packaging needs, there are several key features to consider that can significantly impact efficiency and effectiveness. First and foremost, look for adjustable height and width capabilities. This flexibility allows the machine to handle various box sizes without requiring additional tools or adjustments, streamlining the packaging process for businesses that deal with multiple product lines.

Another essential feature to consider is the sealing method employed by the machine. Bottom case sealers are typically available in tape or glue sealing options. Tape sealers are often more cost-effective and easier to maintain, while glue sealers provide a stronger bond, which is particularly beneficial for heavier or bulkier items. Evaluate your product specifications and shipping requirements to determine which sealing method aligns best with your operational goals.

Finally, consider the speed of the bottom case sealer. An efficient machine can significantly enhance your production rate, particularly in high-volume operations. Look for models that offer quick changeover times and are compatible with automation systems, ensuring seamless integration into your existing packaging processes. By prioritizing these features, you can choose a bottom case sealer that enhances productivity while meeting your specific packaging needs.

Evaluating the Efficiency and Speed of Bottom Case Sealers

When selecting a bottom case sealer for your packaging needs, evaluating the efficiency and speed of the equipment is crucial. According to a report by Smithers Pira, automated packaging solutions can increase productivity by up to 30%, significantly reducing labor costs and ensuring consistent sealing quality. Efficiency in a bottom case sealer is often measured in cases per minute (CPM), with top-performing machines reaching speeds of over 30 CPM. This capability not only optimizes production rates but also allows businesses to meet varying demand levels without compromising quality.

Moreover, the speed of sealing processes plays a vital role in maintaining a streamlined workflow. A case study published in Packaging Strategies highlights that companies using high-speed bottom case sealers reported a 25% reduction in bottlenecks during packaging operations. The synergy between speed and efficiency ultimately impacts the bottom line—effectively supported by research that reveals companies can realize ROI in less than 12 months after investing in advanced sealing technology. With packaging demands continually evolving, equipping your facility with a reliable, high-speed bottom case sealer is essential for staying competitive in the marketplace.

How to Choose the Right Size and Capacity for Your Packaging Needs

When selecting the perfect bottom case sealer, understanding the size and capacity necessary for your packing operation is crucial. Research from the Institute of Packaging Professionals shows that selecting the right equipment can lead to a 25% increase in packaging efficiency. This improvement is particularly significant when you consider the average operational costs associated with packaging, which can account for up to 10% of total expenditure in manufacturing. Assessing your current packaging volume and future projections will help you avoid bottlenecks or under-utilized machinery.

Tip: Always measure the dimensions of your boxes or products before making a selection. Many sealers are designed to handle a specific range of sizes, and opting for a model that offers versatility can save you both time and money in the long run.

Another critical factor is the capacity of the sealer, as some machines are better suited for high-speed production lines while others are designed for lower volume requirements. According to a 2022 report by Packaging Digest, businesses operating at high volumes should consider sealers that can handle over 30 cases per minute. Proper alignment with your production goals will ensure you maintain operational efficiency and flexibility as your packaging needs evolve.

Tip: Evaluate the total cost of ownership, including maintenance and potential downtime, when considering different sealer capacities to make a well-informed decision.

Maintaining Your Bottom Case Sealer for Longevity and Performance

Maintaining your bottom case sealer is crucial for ensuring its longevity and optimal performance in any packaging operation. Regular maintenance not only helps to prevent unexpected breakdowns but also maximizes the efficiency of the sealing process. Start by establishing a routine inspection schedule that includes checking and cleaning critical components such as the sealing pads, belts, and nozzles. Dust and residue can accumulate over time, potentially hindering the equipment’s function. A simple cleaning regime can extend the lifespan of your machine significantly.

Another essential aspect of maintenance is lubrication. Many bottom case sealers have moving parts that require regular lubrication to operate smoothly. Following the manufacturer’s guidelines on which lubricants to use is essential to avoid damage. Additionally, inspecting electrical connections and pneumatic systems for any signs of wear can prevent costly repairs. Keeping a log of maintenance activities can also help in tracking performance trends and identifying potential issues before they escalate, ensuring your bottom case sealer continues to perform at its best.