A-B-C Blog

2026 How to Use a Plaster Saw Effectively?

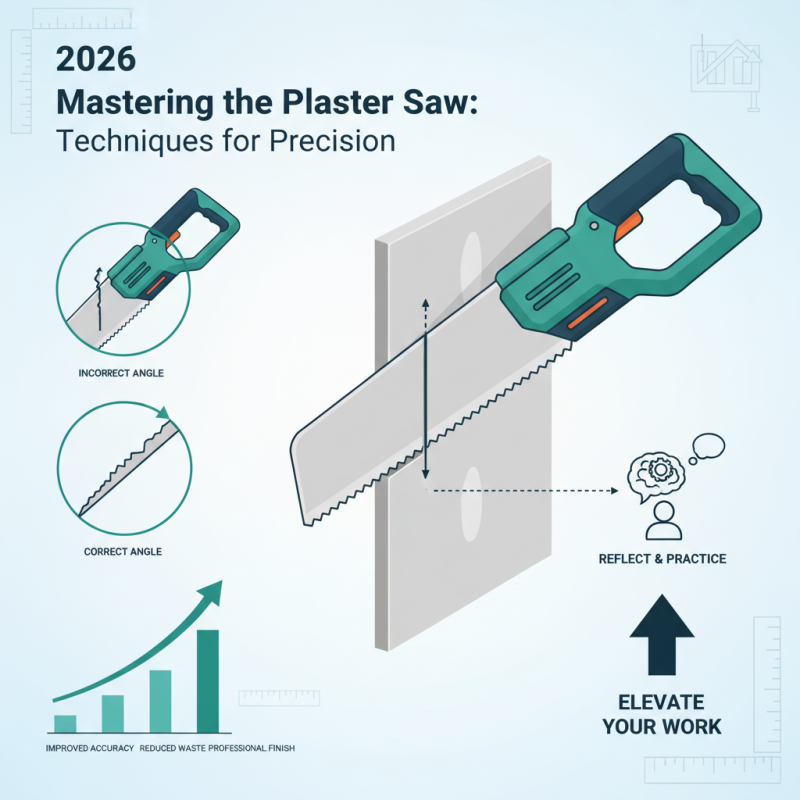

In the construction industry, the effective use of tools is paramount. The Plaster Saw stands out as a critical instrument for achieving precision in drywall and plastering projects. According to a recent industry report by the National Association of Home Builders, over 70% of successful plaster installations depend on the right tools. Expert Mark Thompson states, “A Plaster Saw not only enhances accuracy but also significantly reduces waste.” This highlights the importance of mastering this tool.

However, many tradespeople still struggle with the Plaster Saw's techniques. Common mistakes include improper handling and incorrect cutting angles. An efficient cut can mean the difference between a professional finish and costly repairs. Additionally, industry statistics reveal that 65% of novices miscalculate their cuts, leading to rework.

The Plaster Saw requires practice, but with the right approach, even beginners can improve. Reflecting on one's technique is crucial for success. Understanding the nuances of this tool can empower professionals to elevate their work standards. Embracing this learning process is key to leveraging the full potential of the Plaster Saw.

Understanding the Basics of a Plaster Saw and Its Components

A plaster saw is a vital tool for professionals and DIY enthusiasts alike. Understanding its components can enhance your efficiency. The primary parts include the blade, motor, and base. The blade's design allows precise cuts in plaster materials. The motor provides the necessary power for effective operation. The base stabilizes the saw during cutting, ensuring accuracy.

Tip: Always inspect the blade before use. A dull blade can lead to uneven cuts. Remember to wear safety gear to protect against debris. A well-maintained saw enhances productivity.

If you’re a beginner, practice cutting on scrap materials. This helps you understand the tool's behavior. Adjust your grip and stance for better control. Effective use of the saw requires patience and practice. Over time, you'll develop a rhythm, making your work easier. Mistakes will happen, but they are part of learning. Reflect on each attempt to improve your technique.

Tip: Clean your plaster saw regularly. A clean tool works more efficiently and lasts longer. After each use, make sure to remove plaster dust and debris. This simple step can prevent future problems.

2026 How to Use a Plaster Saw Effectively?

Choosing the Right Plaster Saw for Your Project Needs

Choosing the right plaster saw for your project can significantly impact your outcome. When selecting a saw, consider the blade type. A serrated blade is great for cutting through thicker materials. On the other hand, a fine-toothed blade works best for precise cuts.

Think about the size and weight of the saw. A lightweight saw is easier to manage but may lack power. A heavier tool often provides better strength and stability. However, you risk fatigue during extended use. Balancing these factors is crucial.

The length of the blade matters too. Longer blades can cut deeper but may be harder to control. A short blade offers more maneuverability, but it limits cutting depth. Ultimately, reflect on your project needs. What challenges are you facing? Take time to evaluate your options before making a choice. Making a hasty decision can lead to frustration later.

Preparing Your Workspace for Safe and Efficient Cutting

Preparing your workspace is crucial for using a plaster saw effectively. A clean, organized area minimizes distractions. Start by clearing any clutter from your workspace. This can help avoid accidents that stem from a chaotic environment. Lay down a drop cloth to catch debris and protect your flooring.

Next, ensure you have adequate lighting. Poor visibility can lead to mistakes. Natural light works well, but additional task lighting is a good idea. Position your saw on a sturdy table or platform. This will provide stability while cutting. If the surface wobbles, it can lead to uneven cuts.

Don't forget about safety gear. Use goggles to protect your eyes from dust. Wear a mask to prevent inhaling particles. Gloves offer grip while shielding your hands. Reflect on your cutting technique regularly. A small mistake in setup can lead to larger issues later on. Always check your setup before you begin. Planning ahead is key to efficiency and safety.

Step-by-Step Guide to Using a Plaster Saw Effectively

Using a plaster saw effectively requires practice and care. Start by securing the plasterboard on a stable surface. This prevents movement during cutting. Measure and mark your cutting line accurately. Use a pencil for clear visibility. If the line is not straight, it may lead to uneven edges. Cut slowly and steadily. Allow the saw to do the work. Pressing too hard can lead to accidents or rough cuts.

As you begin cutting, maintain a firm grip on the saw. This ensures better control. Be mindful of any resistance you feel. Adjust your angle or speed as necessary. If you find yourself forcing the saw, it may mean you're on the wrong path. Review your position. After each cut, inspect the edges. Are they clean? If not, consider going back to refine them. Mistakes are part of the learning process. Embrace them to improve your technique over time.

Maintaining and Storing Your Plaster Saw for Longevity

Proper maintenance and storage of your plaster saw can significantly extend its lifespan. According to industry reports, tools like plaster saws can last up to five years with the right care. This longevity is often overlooked by many users. Regular cleaning after each use is essential. Dust and plaster residue can accumulate, affecting the blade's performance. A simple brush or cloth can do wonders in keeping your saw clean.

When it comes to storage, temperature matters. A damp or overly humid environment can lead to rust, degrading the tool. Reports show that nearly 30% of tool damage comes from improper storage. Keeping your plaster saw in a dry, climate-controlled area is vital. Avoid storing it in a toolbox with other metal tools, as this can cause scratches and further damage.

Lastly, inspecting your plaster saw regularly is crucial. Look for signs of wear and tear. A chipped blade may lead to uneven cuts, affecting your project quality. Regular maintenance is not just about keeping the tool in shape. It’s about ensuring safety and efficiency. Users often underestimate the impact of small damages. Ultimately, a little effort can save time and money.