A-B-C Blog

Innovative Applications of Best Bottom Case Sealer in Global Packaging Solutions

In the ever-evolving landscape of packaging solutions, the Bottom Case Sealer stands out as a pivotal innovation that enhances efficiency and reliability in product packaging. As businesses strive to meet the demands of a global market, implementing cutting-edge sealing technologies has become essential. This ultimate guide delves into the transformative applications of the Bottom Case Sealer, exploring its versatility across various industries and its role in optimizing supply chain processes. From streamlining operations to ensuring product integrity, the Bottom Case Sealer not only addresses the challenges faced by manufacturers but also sets a new standard for packaging excellence. Join us as we uncover how this innovative technology is shaping the future of packaging solutions worldwide.

Revolutionizing Packaging: The Role of Best Bottom Case Sealers

In today's rapidly evolving packaging landscape, the introduction of Best Bottom Case Sealers is poised to revolutionize the industry. These innovative sealing solutions not only enhance the efficiency of packaging processes but also align perfectly with the growing demand for sustainability. As companies explore eco-friendly practices, such as the circular economy and the use of bioplastics, Best Bottom Case Sealers can play a crucial role in minimizing material waste and ensuring reliable closures that withstand transportation challenges.

Moreover, the integration of advanced technologies in packaging, including IoT and AI, complements the functionality of Best Bottom Case Sealers by optimizing production lines and promoting smarter, more responsive packaging systems. With the rising urgency for recyclable and sustainable packaging solutions, these sealers can significantly contribute to reducing the environmental impact of packaging operations. By facilitating a more sustainable and streamlined approach to packaging, Best Bottom Case Sealers are not just an innovation; they represent a necessary evolution in the quest for a greener future.

Key Features of Best Bottom Case Sealers for Global Applications

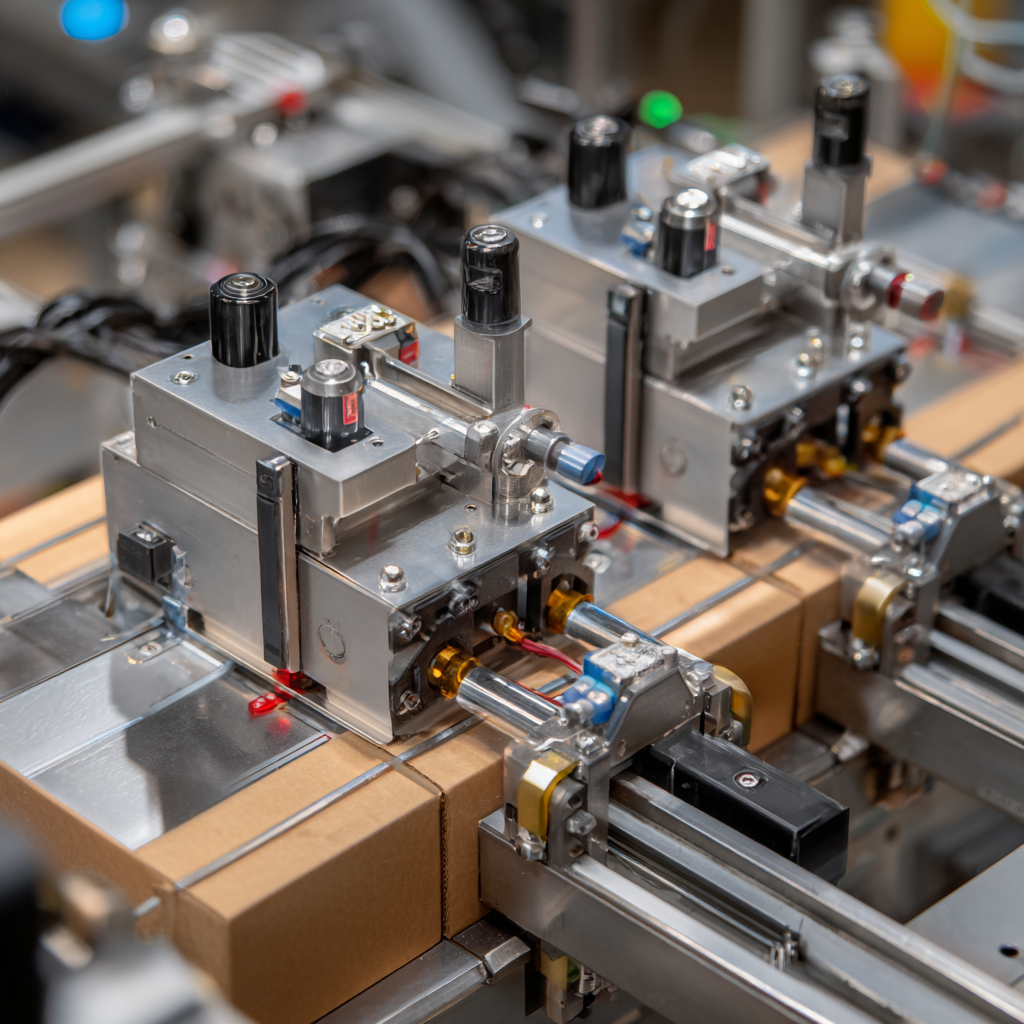

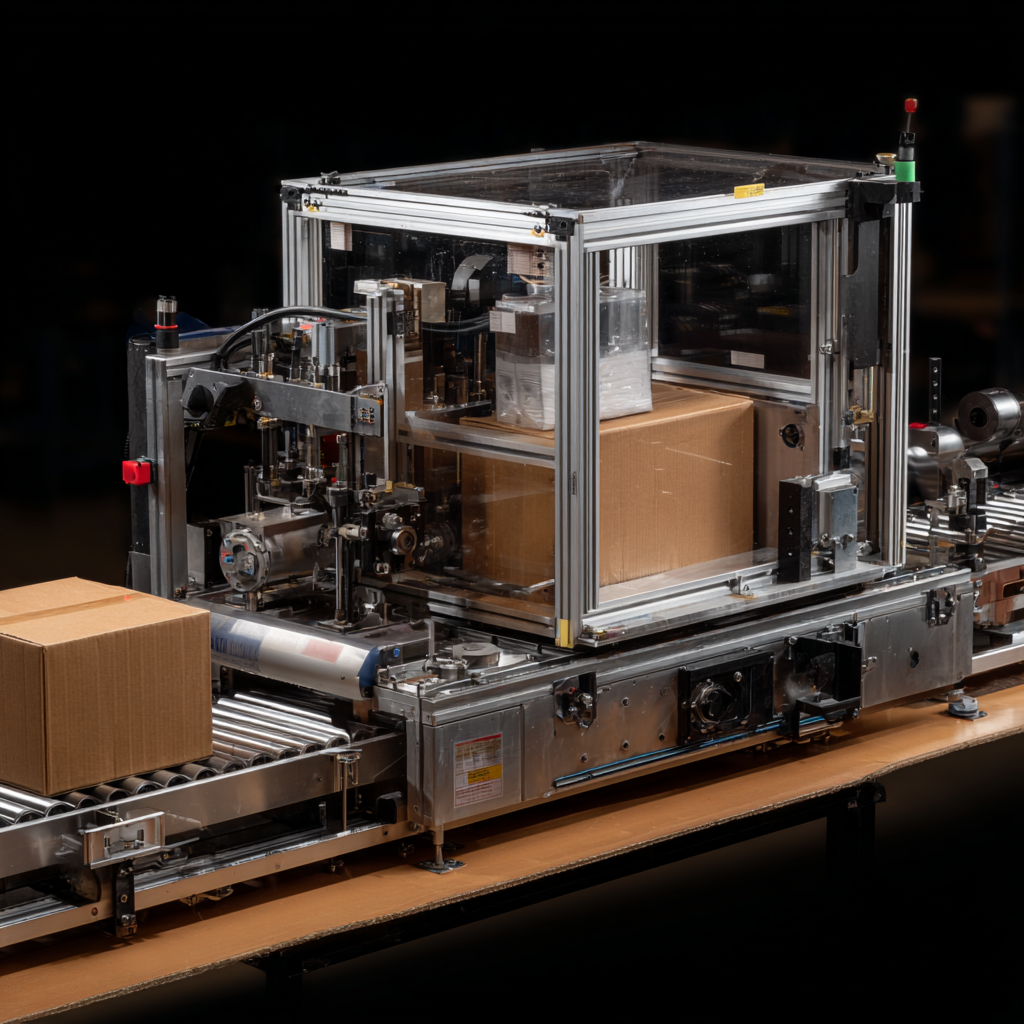

The Best Bottom Case Sealer has emerged as a crucial tool in modern packaging solutions across various industries. One of its key features is its versatility, enabling it to efficiently seal cases of different sizes and materials. This adaptability allows businesses to streamline their operations, improving overall productivity while maintaining high standards in product protection. Furthermore, its user-friendly design simplifies the sealing process, making it an ideal choice for companies looking to optimize their packaging lines without extensive training for their workforce.

Another significant aspect of the Best Bottom Case Sealer is its advanced sealing technology, which ensures watertight and tamper-proof closures. This is particularly vital for industries such as food and beverage, pharmaceuticals, and e-commerce, where product integrity is paramount. Additionally, many models are equipped with automatic adjustments, allowing for quick changeovers between different case sizes without compromising sealing quality. This feature not only enhances operational efficiency but also reduces downtime, making the Best Bottom Case Sealer an invaluable asset for global packaging applications.

Exploring Industry-Specific Uses of Bottom Case Sealers

In today's rapidly evolving packaging industry, bottom case sealers are becoming indispensable tools across various sectors. Their innovative applications not only enhance efficiency but also ensure product safety throughout the supply chain. Specifically, in sectors like consumer electronics and automotive, the demand for robust packaging solutions to protect sensitive components has surged. The battery cell structural component industry, for example, is experiencing considerable growth, with projections indicating a market size of approximately 78 billion yuan by 2026, driven by a compound annual growth rate (CAGR) of 30%. This upward trend emphasizes the necessity for reliable sealing solutions that can withstand the challenges posed by high-speed production lines and stringent safety standards.

Moreover, companies are increasingly utilizing bottom case sealers to form formidable barriers against contamination and damage, effectively safeguarding critical components during transportation. As the electric cell structural components industry faces a temporary dip in capacity utilization, advancements in sealing technologies are playing a pivotal role in stabilizing production processes. By integrating state-of-the-art bottom case sealers tailored to specific industry needs, manufacturers can not only enhance operational efficiency but also build a competitive edge against market fluctuations. The strategic deployment of these sealing solutions illustrates how industry-specific applications can lead to significant advancements in the overall packaging landscape.

Sustainability and Efficiency: How Best Bottom Sealers Enhance Packaging

The packaging industry is rapidly evolving, and sustainability has become a pivotal concern for businesses worldwide. Best Bottom Case Sealers play a crucial role in enhancing packaging efficiency while minimizing environmental impact. These innovative machines are designed to optimize the sealing process, ensuring that packaging is not only secure but also made from sustainable materials. By enabling companies to use eco-friendly substrates, Best Bottom Sealers contribute to reducing the overall carbon footprint of packaging operations.

Efficiency is another significant benefit of Best Bottom Case Sealers. They streamline the packaging process by automating the sealing of cases, which not only saves time but also reduces material waste. By implementing these sealers, businesses can optimize their production lines, allowing for quicker turnaround times and lower labor costs. This efficiency translates directly into cost savings, making sustainable practices more accessible to companies striving for eco-conscious operations. The combination of sustainability and efficiency makes Best Bottom Case Sealers an essential component of modern packaging solutions that meet global demands.

Future Trends in Packaging Solutions with Bottom Case Sealers

The evolution of packaging solutions is witnessing a remarkable shift towards sustainability and efficiency, particularly with the growing application of bottom case sealers. These innovations emphasize the need for environmentally friendly alternatives, as seen in the recent move towards paper-based designs in packaging. The simplification of the sealing process not only reduces material usage but also enhances the overall aesthetic appeal of product packaging, enabling brands to cultivate stronger connections with eco-conscious consumers.

As we look to the future, it is essential to consider how these advancements in bottom case sealers will shape the packaging industry. The technological improvements in sealing mechanisms enhance production efficiency while maintaining product integrity. However, the removal of plastic coverings raises concerns about the potential for counterfeit goods, especially in a market flooded with refurbishment activities. Addressing these challenges requires collaboration between manufacturers and retailers to ensure that sustainable practices do not compromise product authenticity, thereby fostering a responsible approach to packaging.