A-B-C Blog

Revolutionizing Supply Chains: The Future of Industrial Packaging Machines

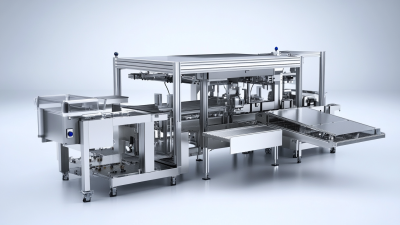

The landscape of supply chains is undergoing a transformative shift, driven by advancements in technology and the increasing demand for efficiency and sustainability. At the forefront of this revolution are

Industrial Packaging Machines, which play a pivotal role in optimizing packaging processes while minimizing waste and reducing operational costs. As industries strive for innovation, understanding

the integration of digital solutions into these machines becomes essential. This article explores the future of industrial packaging, highlighting key trends and offering practical tips for businesses looking to enhance their packaging systems.

With the right approach, companies can leverage Industrial Packaging Machines to not only streamline their operations but also meet the evolving needs of consumers and the environment, ultimately setting the stage for a more resilient and agile supply chain.

With the right approach, companies can leverage Industrial Packaging Machines to not only streamline their operations but also meet the evolving needs of consumers and the environment, ultimately setting the stage for a more resilient and agile supply chain.

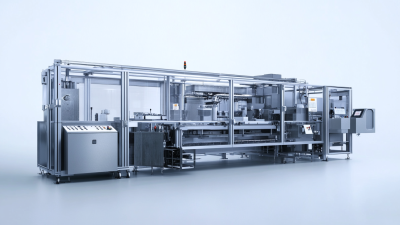

The Role of Automation in Enhancing Industrial Packaging Efficiency

The future of industrial packaging is increasingly intertwined with automation, as machines evolve to meet the demands of a rapidly changing supply chain landscape. According to a report by MarketsandMarkets, the global industrial automation market is projected to grow from $175 billion in 2020 to over $300 billion by 2026, reflecting an annual growth rate of around 10%. This surge is driven by the need for efficiency, accuracy, and a reduction in labor costs. Automation in packaging not only streamlines processes but also tackles the issue of labor shortages that many industries are currently facing.

Enhanced automation technologies, such as robotic arms and smart conveyors, are revolutionizing the way products are packaged. For instance, a study by Zebra Technologies revealed that 80% of manufacturers plan to implement advanced automation in their processes within the next two years. These technologies minimize human error and increase throughput, making it possible to respond swiftly to market demands. Additionally, integrating Internet of Things (IoT) capabilities allows for real-time monitoring and data analysis, which helps optimize packaging lines and reduce waste, ultimately leading to cost savings and increased sustainability in industrial packaging practices.

Revolutionizing Supply Chains: The Impact of Automation on Packaging Efficiency

This chart illustrates the enhancements in packaging efficiency due to automation across various sectors. The data shows the percentage improvement in packaging speed from 2018 to 2023.

Sustainability Practices in Modern Packaging Solutions

In the context of rapid advancements in technology and increasing environmental awareness, sustainability practices in modern packaging solutions have become paramount. According to a recent report by Grand View Research, the global green packaging market is expected to reach $1.2 trillion by 2027, growing at a CAGR of 5.7%. This growth reflects a significant shift towards eco-friendly materials and processes that minimize waste and carbon footprints. Industrial packaging machines are now being designed not only for efficiency but also for sustainability, incorporating materials that are recyclable, biodegradable, or made from renewable resources.

Tips for Sustainable Packaging Practices:

1. Evaluate Material Choices: Prioritize materials that are either recycled or easily recyclable. Sustainable materials can reduce emission levels during production and enhance the overall environmental value of your packaging.

2. Optimize Machine Efficiency: Invest in state-of-the-art industrial packaging machines that use less energy and produce minimal by-products. Efficient machines not only save costs but also contribute to a greener supply chain.

As industries evolve, the integration of sustainable packaging practices becomes not just a regulatory requirement but a market demand. Companies adopting these practices can benefit from reduced material costs, enhanced brand reputation, and increased consumer loyalty, ultimately driving a more responsible industrial packaging future.

Integrating IoT Technology for Smart Supply Chain Management

The integration of Internet of Things (IoT) technology into supply chain management is poised to reshape the future of industrial packaging machines. With the global supply chain management market projected to grow from $26.25 billion in 2024 to $63.77 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 11.7%, companies are increasingly adopting digital solutions to optimize their operations. The digital transformation facilitated by IoT and artificial intelligence (AI) not only enhances operational efficiency but also provides real-time insights that are crucial for effective decision-making.

Experts in the field emphasize that the application of data-driven strategies and AI technologies is critical during this transitional phase in supply chain management. The successful implementation of these technologies can lead to improved inventory management, reduced costs, and enhanced customer satisfaction. As seen in recent evaluations by the State-owned Assets Supervision and Administration Commission, companies that embrace digitalization and AI in their supply chains are being recognized as leaders in this evolving landscape, establishing benchmarks for others to follow. The emphasis on integrating smart technologies is not just a trend; it is becoming essential for companies aiming to maintain a competitive edge in an increasingly complex and dynamic market.

Revolutionizing Supply Chains: The Future of Industrial Packaging Machines - Integrating IoT Technology for Smart Supply Chain Management

| Dimension | Data Type | Example Metrics | Benefits |

|---|---|---|---|

| Operational Efficiency | Percentage (%) | 85% efficiency | Reduced Waste |

| Cycle Time | Time (minutes) | 15 minutes | Faster Turnaround |

| Cost Reduction | Dollars ($) | $10,000 savings | Improved Profitability |

| Product Quality | Rating (1-10) | 9.5 | Increased Customer Satisfaction |

| Supply Chain Visibility | Percentage (%) | 70% visibility | Enhanced Monitoring |

Customization Trends in Industrial Packaging Machines

The customization trends in industrial packaging machines are increasingly transforming the landscape of supply chains, driven by the need for enhanced flexibility and efficiency. As industries evolve, there is a marked shift towards machines that can adapt to varied product types and sizes, allowing businesses to respond swiftly to market demands. This shift is not merely about accommodating different package designs but also about integrating advanced technologies that enable real-time adjustments during production processes.

Moreover, the integration of artificial intelligence (AI) into packaging machinery is setting new benchmarks in customization. Through the use of machine learning, computer vision, and predictive analysis, companies can optimize packaging solutions tailored to specific customer requirements, thus minimizing waste and maximizing productivity. As the market for automated packaging solutions continues to grow, projected to reach over USD 140 billion by 2033, the emphasis will be on developing intelligent systems that support customized packaging efficiently, ensuring that companies can maintain a competitive edge in a rapidly changing industrial environment.

The Impact of Robotics on Packaging Workflow Optimization

The integration of robotics into industrial packaging processes is not just a trend but a fundamental shift that enhances workflow efficiency and reduces operational costs. According to a report by the International Federation of Robotics, the global market for robotic systems is expected to reach $23 billion by 2025, with packaging applications accounting for a significant portion of that growth. Automated systems, including robotic arms and collaborative robots (cobots), can operate around the clock, boosting throughput by an estimated 30-50% compared to traditional manual methods.

Furthermore, the deployment of robotics in packaging allows for greater precision and consistency, minimizing errors and waste in the supply chain. A study by McKinsey & Company revealed that companies using advanced robotics in their packaging processes saw an average reduction in operational costs by 20-25% while improving packing speed by up to 50%. This not only leads to faster delivery times but also enhances overall product quality, leading to increased customer satisfaction and loyalty. As industries continue to adapt to changing market demands, robotics will play a crucial role in redefining packaging workflows for the future.

Related Posts

-

Comprehensive Insights on Industrial Packaging Machines for Global Buyers

-

2025 Breakthroughs in Industrial Packing Machines: A Comprehensive Guide for Businesses

-

Unmatched Quality in Global Export of Premium Industrial Packing Machines Made in China

-

Global Quality Packaging Solutions Empowering International Trade from China

-

7 Essential Insights for Sourcing the Ideal Case Erector Machine Globally

-

Revolutionizing Your Production Line with Innovative Industrial Packing Machines