A-B-C Blog

Understanding the Role of Depalletizer Machines in Modern Automated Warehousing Solutions

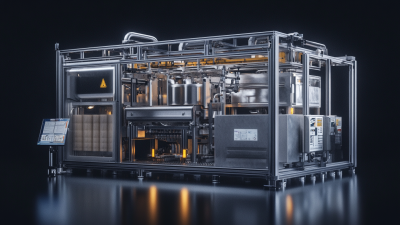

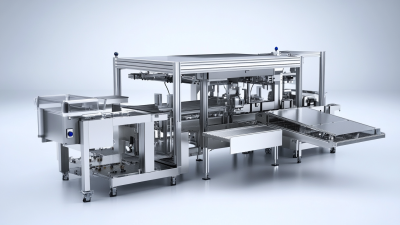

In the rapidly evolving landscape of modern automated warehousing, the role of the Depalletizer Machine has become increasingly critical.

According to a report by MarketsandMarkets, the automated warehousing market is projected to grow from USD 14.02 billion in 2020 to USD 30.99 billion by 2026, highlighting the demand for efficiency and advanced operational technologies in logistics.

Depalletizer Machines are at the forefront of this transformation, enabling the swift and accurate unloading of products from pallets, which is essential for streamlining inventory management and reducing labor costs.

A study conducted by Research and Markets indicates that warehouses employing automation technologies can improve order fulfillment speed by up to 33%.

As industries seek to optimize their supply chains and enhance productivity, understanding the integration and functionality of Depalletizer Machines emerges as a crucial component in the development of effective and efficient warehousing solutions.

In the rapidly evolving landscape of modern automated warehousing, the role of the Depalletizer Machine has become increasingly critical.

According to a report by MarketsandMarkets, the automated warehousing market is projected to grow from USD 14.02 billion in 2020 to USD 30.99 billion by 2026, highlighting the demand for efficiency and advanced operational technologies in logistics.

Depalletizer Machines are at the forefront of this transformation, enabling the swift and accurate unloading of products from pallets, which is essential for streamlining inventory management and reducing labor costs.

A study conducted by Research and Markets indicates that warehouses employing automation technologies can improve order fulfillment speed by up to 33%.

As industries seek to optimize their supply chains and enhance productivity, understanding the integration and functionality of Depalletizer Machines emerges as a crucial component in the development of effective and efficient warehousing solutions.

The Importance of Depalletizer Machines in Streamlining Warehouse Operations

Depalletizer machines play a crucial role in modern automated warehousing solutions by significantly enhancing the efficiency of warehouse operations. By automating the process of unloading bulk products from pallets, these machines reduce the need for manual labor, thereby minimizing human error and boosting overall productivity. With the increasing demand for faster and more accurate order fulfillment, depalletizers help streamline the logistics of handling inventory, allowing businesses to respond more swiftly to customer needs.

Moreover, the implementation of depalletizer machines leads to better space utilization within warehouses. By efficiently organizing products and eliminating the clutter associated with manual depalletizing, these machines help create a more structured and accessible environment. This not only improves worker safety but also facilitates faster inventory management processes. As businesses continue to adopt automation technologies, the importance of depalletizer machines in optimizing warehouse operations cannot be understated, shaping the future of supply chain efficiency.

How Depalletizer Machines Enhance Efficiency in Automated Warehousing

In the realm of modern automated warehousing, depalletizer machines play a crucial role in enhancing operational efficiency. As businesses face increasing demands for automation, particularly within the beverage and food industries, the integration of robotic depalletizers has become a strategic necessity. These machines streamline the unloading process of goods, significantly reducing manual labor and minimizing the risk of errors. As a result, warehouses can deal more effectively with the rising complexity of inventory, driven by an influx of SKUs and the prevalence of mixed pallets.

The efficiency gains provided by robotic depalletizers are evident in various applications, including feed mills and manufacturing facilities. By automating the handling of pallets, these systems not only improve productivity but also enhance safety for workers navigating busy environments. With continuous advancements in automation technology, the future of warehousing looks promising, as intelligent depalletizers contribute to faster processes and a more responsive supply chain. As industries adapt to the evolving landscape, embracing these innovations becomes essential for maintaining a competitive edge.

Key Features of Modern Depalletizer Machines for Optimal Performance

Modern depalletizer machines play a crucial role in enhancing the efficiency of automated warehousing solutions. Key features of these machines are designed to optimize their performance, ensuring that operations run smoothly and effectively. For instance, advanced vision systems allow for precise identification and handling of various product types, facilitating faster processing times. According to a report by MarketsandMarkets, the global automated material handling market, which includes depalletizers, is projected to reach USD 41.9 billion by 2026, highlighting the growing importance of automation in logistics.

Another significant feature is the adaptability of modern depalletizers to handle different pallet sizes and configurations. This flexibility is vital in today's fast-paced distribution environments, where businesses demand quick changes to align with varying product lines. Recent surveys indicate that over 70% of warehouses that have implemented automated systems have reported a decrease in operational costs by as much as 30%, largely attributed to the reliability and reduced labor dependency of automated machines. Additionally, the integration of IoT technology enables real-time monitoring and predictive maintenance, further enhancing the operational efficiency of depalletizers as part of a robust automated warehousing solution.

The Impact of Depalletizer Technology on Supply Chain Management

Depalletizer machines are pivotal in enhancing supply chain management by streamlining the process of unloading pallets in automated warehousing systems. They perform the critical function of converting bulk pallet loads into single items or smaller groups, facilitating efficient product flow. This automation reduces manual handling, minimizes the risk of injury, and allows for faster processing times, which is essential in today’s fast-paced logistics environment.

The integration of advanced depalletizer technology contributes to improved inventory accuracy and spatial efficiency within warehouses. By enabling precise sorting and distribution of goods, these machines not only optimize storage capacity but also enhance order fulfillment rates. As supply chains become increasingly complex, the ability to quickly and reliably process incoming shipments ensures that businesses can respond to consumer demands more effectively, ultimately driving competitive advantage.

Future Trends in Depalletizer Machines and Their Role in Automation

The future of depalletizer machines is intrinsically linked to the evolving landscape of warehouse automation. As companies increasingly adopt advanced robotic solutions, the demand for efficient depalletizing systems has grown significantly. Recent market reports indicate that the global automatic palletizer and depalletizer market is projected to expand from USD 1.70 billion in 2024 to USD 2.30 billion by 2030. This surge reflects a broader trend towards automation aimed at enhancing logistics efficiency and reducing labor costs.

In particular, flexible and gentle depalletizing equipment has become essential for industries such as beverage production, where careful handling is required to maintain product quality. The integration of cognitive robotics and smart machines is also on the rise, indicating a shift towards systems that not only perform repetitive tasks but also adapt to changing operational demands. Policymakers are recognizing the value of promoting robotic automation, seeing it as a critical strategy to boost productivity and resilience in logistics, positioning depalletizers as a vital component in achieving these goals.

Related Posts

-

Finding Quality Suppliers for Best Wrap Around Case Packers Essential Checklist for Global Buyers

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Pallet Dispenser for Your Business

-

Revolutionizing Your Production Line with Innovative Industrial Packing Machines

-

Envisioning Tomorrow: The Evolution of Case Erector Machines in Packaging Industries

-

Comprehensive Insights on Industrial Packaging Machines for Global Buyers

-

How to Choose the Right Container Packaging for Your Business Needs