A-B-C Blog

Ultimate Tips for Choosing a PU Foam Lamination Machine?

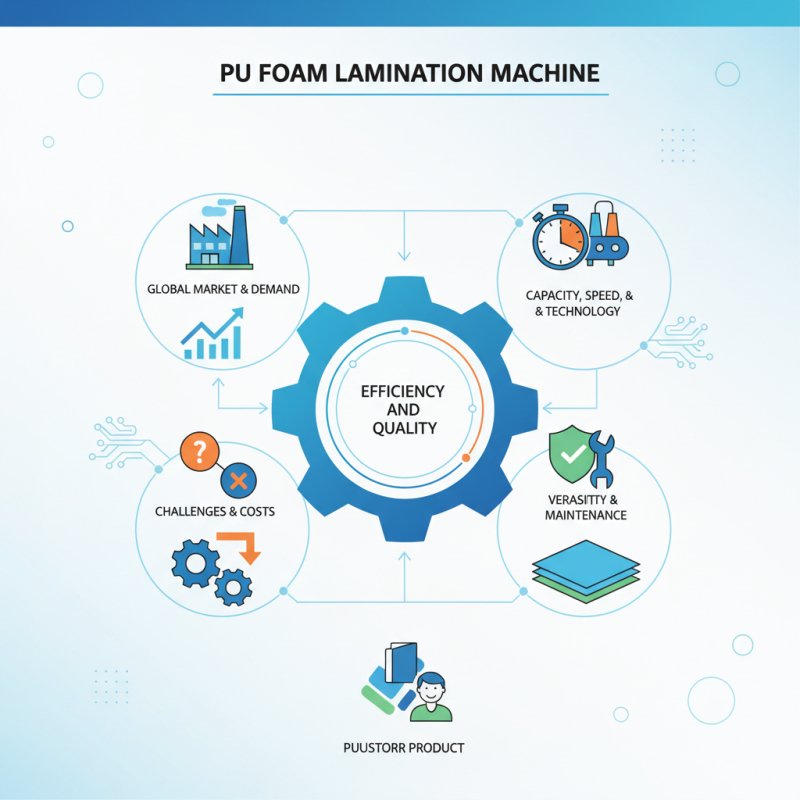

The PU foam lamination machine plays a crucial role in various industries. With the global market for PU foam expected to reach $60 billion by 2026, these machines are in high demand. Companies increasingly seek efficiency and quality in their production processes. Proper selection of a PU foam lamination machine can significantly improve output and reduce costs.

However, choosing the right machine is not straightforward. Factors like machine capacity, speed, and technology must be considered. Research shows that around 30% of businesses face challenges due to inappropriate equipment choices. This often leads to production delays and increased operational costs. Companies must weigh their options carefully to make informed decisions.

Inadequate research may lead to poor investments. A PU foam lamination machine that does not meet operational needs can become a liability. Thus, understanding industry trends and technological advancements is essential. Businesses should look for machines that offer versatility and ease of maintenance. A well-chosen machine can enhance product quality and ensure customer satisfaction.

Understanding the Basics of PU Foam Lamination Machines

PU foam lamination machines are essential in various industries. They provide efficient lamination of polyurethane foam, enhancing durability and appearance. Understanding their basics can help you make informed decisions.

When choosing a machine, consider the type of foam. Not all machines handle every foam variety well. Some may struggle with thicker materials. You could face quality issues if the machine isn’t compatible.

Look into the machine's speed and efficiency. Higher speed can increase output, but may sacrifice quality. Testing a machine's minimum and maximum speed is prudent. Ensure it fits your production needs without compromising lamination quality.

Also, don’t overlook the maintenance aspect. Machines require regular upkeep. A neglected machine can lead to breakdowns and delays. Always check maintenance records and user reviews. Reflecting on these factors will guide your choice wisely.

Key Features to Consider When Selecting a PU Foam Lamination Machine

When selecting a PU foam lamination machine, key features play a critical role. The efficiency of production must not be overlooked. Advanced machines can laminate up to 500 square meters per hour. This capability significantly boosts productivity, especially for large-scale manufacturing. Not all machines, however, maintain this level of efficiency. It’s essential to evaluate performance data from industry reports. Some machines reportedly fall short of expected outputs, affecting overall production timelines.

Quality control is another crucial feature. Look for machines with built-in monitoring systems. These can provide real-time feedback on the lamination process. According to a 2022 industry study, around 35% of production defects arise from poor lamination quality. A reliable machine minimizes these issues, leading to better product integrity.

Tip: Always check the machine’s specifications. Compare them with your production requirements. Consider energy efficiency, as some models consume excessive power. Choosing a machine that balances quality and energy efficiency can save costs in the long run. Additionally, assess the maintenance needs. Some machines require more frequent servicing, which may disrupt production. Reflecting on these aspects can lead to a more informed decision.

Evaluating the Performance and Efficiency of PU Foam Machines

When evaluating the performance and efficiency of PU foam lamination machines, it's essential to consider several factors. According to industry reports, the efficiency of these machines can vary significantly. Machines with higher output rates tend to utilize advanced technology. This leads to more consistent lamination. However, the cost of such machines is often higher. Many manufacturers struggle to balance cost and performance.

Durability also plays a critical role. A machine might perform well initially but could lead to issues over time. Frequent maintenance may be required. Reports indicate that performance degradation impacts productivity rates. Up to 30% of manufacturers experience downtime due to equipment failure. This statistic highlights the need for thorough evaluations.

Energy consumption is another vital factor. Machines that use excessive energy can inflate operational costs. Some reports suggest that companies could save up to 25% in costs by choosing energy-efficient models. Yet, these options might come with a higher upfront expense. It creates a challenge for businesses when aiming for sustainability and cost-effectiveness. Choosing the right PU foam lamination machine is not just about performance; it requires a comprehensive assessment of all these factors.

Maintenance and Support Services for PU Foam Lamination Machines

When selecting a PU foam lamination machine, maintenance and support services are critical factors. Regular maintenance can enhance machine performance and longevity. According to a recent industry report, proper maintenance can increase equipment life by up to 30%. Neglecting maintenance may lead to costly repairs and downtime. A machine that isn’t well cared for will have lower efficiency and higher operating costs.

Many manufacturers offer maintenance packages, but they vary significantly. Some companies provide comprehensive services including preventive checks and rapid response teams. Others may only offer basic support. A lack of quality service options can be a problem. Reports indicate that 25% of users experienced significant delays due to insufficient support for their machines. Ensuring you have reliable service is vital for operational continuity.

Access to support services can also influence your purchasing decision. It’s essential to evaluate not only the machine but the after-sales support. Consider how fast technicians can respond to an emergency. Additionally, think about whether you can source spare parts easily. These factors greatly influence your potential productivity. Skipping over them might result in unforeseen challenges down the road.

Ultimate Tips for Choosing a PU Foam Lamination Machine - Maintenance and Support Services for PU Foam Lamination Machines

| Feature | Description | Importance Rating (1-5) | Maintenance Frequency | Support Services |

|---|---|---|---|---|

| Machine Efficiency | Measure of the output versus energy consumption | 5 | Monthly | 24/7 support availability |

| Material Compatibility | Ability to work with different foam types and thicknesses | 4 | Quarterly | Technical assistance for material selection |

| User-Friendly Interface | Ease of use for operators with minimal training | 5 | As needed | User training sessions available |

| Durability | Longevity of machine components and overall build quality | 4 | Annually | Warranty and repair services |

| After-Sales Support | Availability of assistance after purchase for optimal performance | 5 | Ongoing | Scheduled check-ups and rapid response |

Cost Considerations: Budgeting for Your PU Foam Lamination Investment

When budgeting for a PU foam lamination machine, consider all factors carefully. The initial purchase price is just the starting point. Additional costs can quickly add up. For instance, maintenance expenses can reach up to 15% of the machine's cost annually. It's crucial to account for these ongoing expenses in your financial planning.

Studies indicate that companies often underestimate operational costs. A report from the International Journal of Manufacturing indicates that labor, energy, and materials can collectively amount to an additional 30-40% of the machine's base price. Therefore, always factor these into your budget calculations.

Choosing a machine also involves reflecting on efficiency. Higher efficiency can lead to cost savings. However, machines with advanced features may have a higher upfront cost. Evaluating the return on investment (ROI) is essential. Are the long-term benefits worth the initial expense? Each business will have different needs, making personalized assessment vital.