A-B-C Blog

Envisioning Tomorrow: The Evolution of Case Erector Machines in Packaging Industries

Envisioning Tomorrow: The Evolution of Case Erector Machines in Packaging Industries

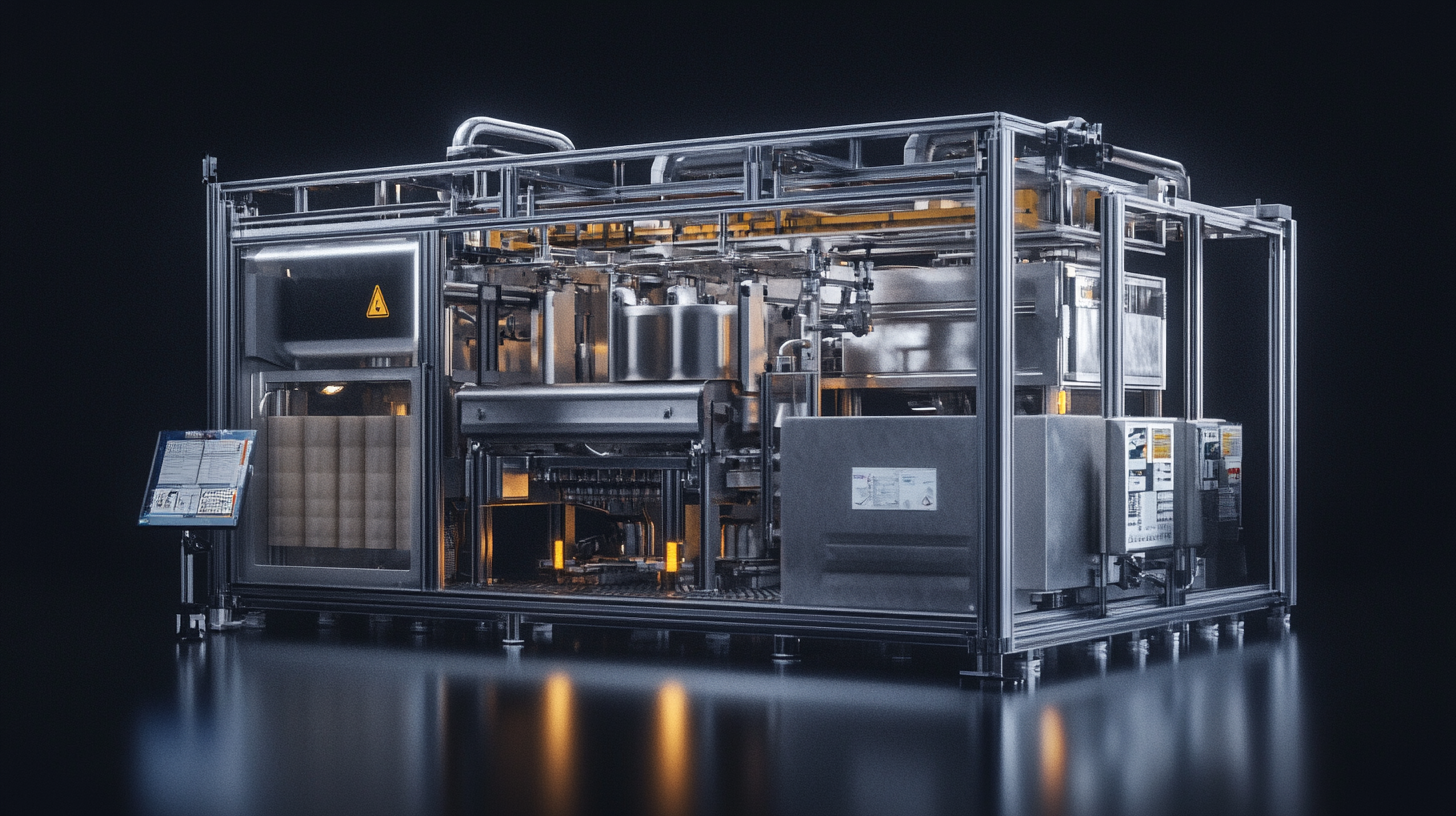

As the packaging industry continues to adapt to rapid technological advancements and changing consumer demands, the role of Case Erector Machines has become increasingly pivotal. According to a report by Smithers Pira, the global packaging market is projected to reach USD 1 trillion by 2024, driven largely by innovations in automation and efficiency. Case erecting machines, integral to this evolution, not only streamline the packaging process but also enhance product safety and integrity. With features like precise folding and high-speed operation, these machines cater to diverse sectors, including food and beverage, pharmaceuticals, and e-commerce.

Moreover, the demand for sustainable packaging solutions is reshaping the landscape, positioning Case Erector Machines as vital players in achieving eco-friendly goals. A report from Freedonia Group indicates that the use of automated packaging systems could lead to a reduction in material waste by up to 30%, aligning with global sustainability initiatives. As we delve into the transformative journey of Case Erector Machines, it becomes clear that their evolution is not just about technological advancements but is also a response to the packaging industry's need for efficiency, adaptability, and environmental responsibility in tomorrow’s market.

The Historical Development of Case Erector Machines in Packaging

The historical development of case erector machines in the packaging industry reflects a trajectory marked by innovation and efficiency. Initially, packaging was a manual task, labor-intensive and often inconsistent in quality. As industries grew and the demand for packaged goods surged, manufacturers recognized the need for automated solutions. The first case erectors emerged in the mid-20th century, primarily designed to improve productivity in bottling and canning operations. These early machines transformed flat cardboard sheets into fully formed boxes, setting the standard for bulk packaging processes. As technology progressed, so did the sophistication of case erector machines. The introduction of automation features in the 1980s allowed for better precision and speed, enabling companies to meet the increasingly rapid pace of production demands. Modern case erectors now boast advanced mechanisms for box folding, sealing, and integration with other packaging lines. These enhancements have led to drastic reductions in labor costs and increased output, making them indispensable in sectors ranging from food to pharmaceuticals. Furthermore, the rise of e-commerce has spurred new innovations in case erector design. Today’s machines not only cater to traditional packaging needs but are also equipped to handle varying box sizes and styles, accommodating the unique demands of online retail. The evolution of case erector machines exemplifies a broader trend in the packaging industry—balancing efficiency with evolving market requirements, while continually enhancing the quality and sustainability of packaged products.

Key Technologies Driving the Evolution of Case Erector Machines

The packaging industry has witnessed remarkable transformations over the past few decades, largely driven by innovations in case erector machines (CEMs). These machines are crucial for automating the process of erecting and sealing cardboard cases, a vital step in packaging that enhances efficiency and reduces labor costs. According to a recent report by MarketsandMarkets, the global packaging machinery market is projected to grow from $47.3 billion in 2020 to $65.4 billion by 2025, with case erectors playing a significant role in this growth.

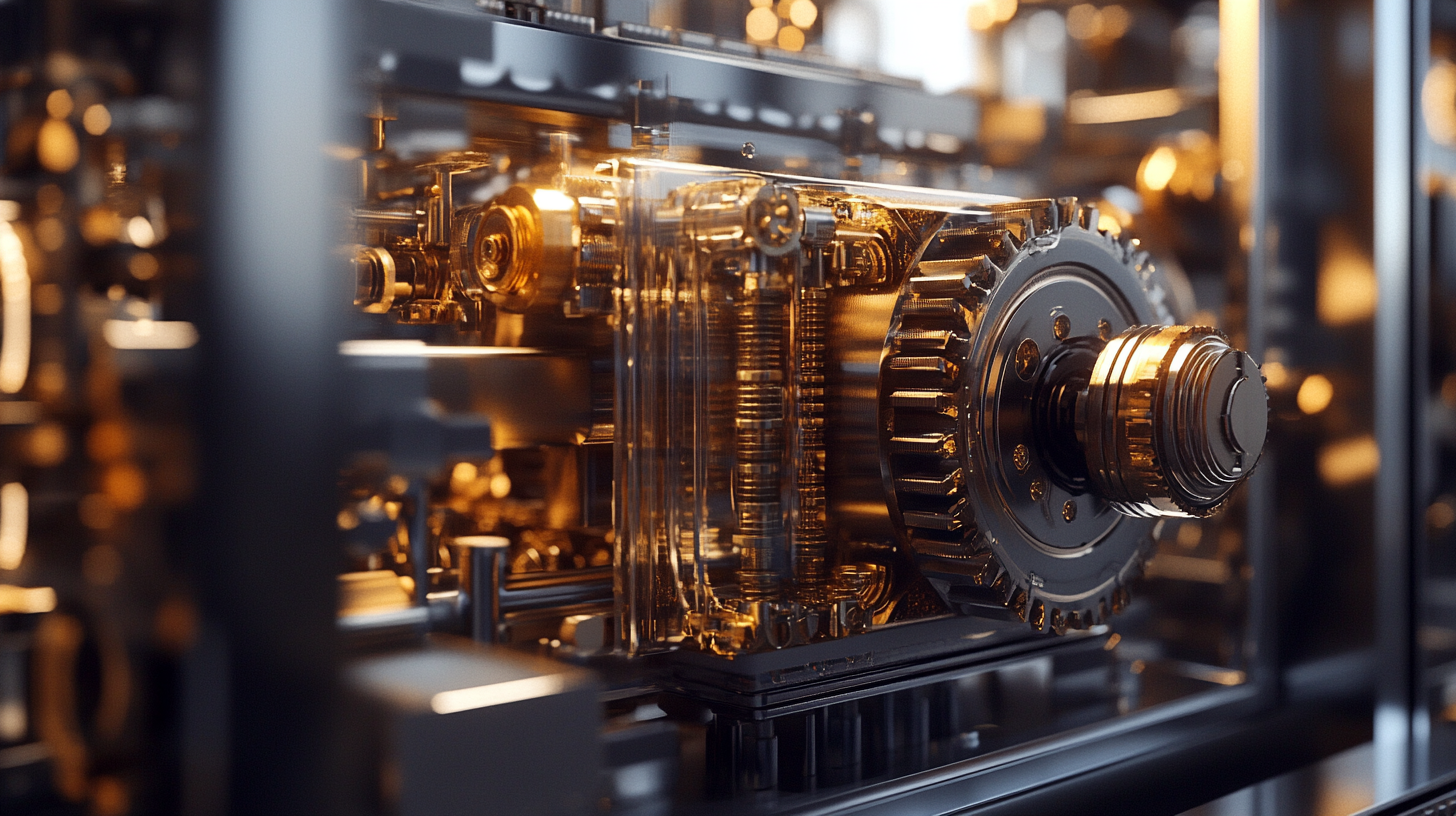

One of the key technologies propelling the evolution of case erector machines is robotics. Advanced robotic systems have improved precision and speed in case erection, adapting to various box sizes and shapes seamlessly. The integration of artificial intelligence (AI) allows these systems to learn and optimize their operations in real-time, leading to reduced downtime and increased productivity. A study from Research and Markets highlights that the demand for robotic packaging solutions is expected to reach a valuation of $5.8 billion by 2027, further emphasizing the importance of these technologies in the future of packaging.

Another technology advancing CEMs is the use of IoT (Internet of Things) capabilities, enabling machines to connect and communicate with each other. This connectivity facilitates predictive maintenance, allowing manufacturers to anticipate mechanical failures before they occur, thereby minimizing disruptions in production. A report from Statista indicates that the number of IoT-connected devices is estimated to exceed 75 billion by 2025, which will likely influence how case erectors are utilized in smart factories.

Overall, the evolution of case erector machines is marked by an infusion of robotics, AI, and IoT technologies. As the packaging industry continues to evolve, these innovations will play a pivotal role in enhancing efficiency and adaptability in packaging operations, ensuring companies stay competitive in a rapidly changing market.

Innovations in Automation and Their Impact on Packaging Efficiency

The packaging industry has undergone significant transformations in recent years, primarily driven by innovations in automation. At the forefront of this evolution are case erector machines, which have become indispensable for enhancing operational efficiency. These machines automate the process of creating and forming boxes, significantly reducing the labor intensity traditionally associated with manual packaging. As industries realize the cost savings and efficiency improvements afforded by these automated solutions, more businesses are integrating advanced technologies into their production lines.

The latest advancements in automation have not only increased speed but also improved accuracy in the packaging process. Modern case erectors are equipped with sophisticated sensors and software that enable precise box formation and alignment, minimizing the potential for errors that could lead to product damage or waste. This precision is vital in maintaining the integrity of goods during transit, ultimately elevating customer satisfaction levels. Furthermore, the ability to handle multiple box sizes and styles with ease offers flexibility that was previously unattainable with manual processes.

Additionally, these innovations have profound implications for sustainability in the packaging industry. Automated case erectors can optimize material usage by ensuring that boxes are dimensionally accurate to the products they hold, thereby reducing excess cardboard waste. Companies that adopt these automated systems often report not only greater productivity but also a commitment to environmentally responsible practices, aligning with the growing consumer demand for sustainable packaging solutions. As we envision the future, it is clear that automation and technology will continue to be game-changers in enhancing packaging efficiency across various industries.

Sustainability Trends in Modern Case Erector Design

In recent years, the packaging industry has witnessed a significant shift towards sustainability, particularly in the design and operation of case erector machines. As businesses increasingly prioritize eco-friendly practices, manufacturers are innovating their equipment to not only improve efficiency but also reduce their environmental impact. According to a report by Smithers Pira, sustainable packaging is predicted to grow at a CAGR of 9.2% from 2020 to 2025, indicating a clear market trend that demands a rethinking of traditional manufacturing processes.

Modern case erector designs are implementing several sustainable practices, such as utilizing recyclable materials and minimizing energy consumption. A recent analysis found that machines optimized for energy efficiency can reduce operational costs by up to 30%, while also cutting greenhouse gas emissions significantly. This combination of economic and environmental benefits is driving companies to invest in advanced machinery that aligns with their sustainability goals.

Furthermore, the incorporation of modular designs in case erectors allows for easy upgrades and adaptability, prolonging the lifecycle of the equipment. This flexibility not only supports manufacturers in meeting evolving regulatory requirements but also enhances their corporate responsibility initiatives. As the demand for sustainable solutions continues to rise, case erector machines will undoubtedly play a crucial role in shaping a more environmentally-conscious packaging landscape.

Future Prospects: The Role of AI and IoT in Packaging Solutions

As the packaging industry witnesses rapid transformations, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is paving the way for smarter and more efficient packaging solutions. These technologies are not just enhancing existing processes but are fundamentally changing the landscape of how goods are packaged, shipped, and delivered. By utilizing AI algorithms, manufacturers can optimize case erecting processes, minimizing material waste and reducing production costs while ensuring consistent quality.

IoT-enabled devices contribute significantly by offering real-time data collection and analysis. For instance, smart sensors can monitor machinery performance, predicting potential failures and allowing for predictive maintenance. This not only extends the lifecycle of equipment like case erectors but also ensures minimal downtime in production lines. Furthermore, the interconnectivity of smart devices enables better inventory management and supply chain visibility, facilitating a leaner and more responsive operation.

As we move towards a data-driven future, the potential applications for AI and IoT in the packaging domain are boundless. From automating routine tasks to providing insights that enable better decision-making, these technologies will help businesses adapt to market demands. The evolution of case erecting machines will, therefore, not only enhance operational efficiencies but also promise a future where packaging aligns more closely with sustainable practices and consumer expectations.