A-B-C Blog

Top 10 Tips for Choosing a Robotic Case Packer?

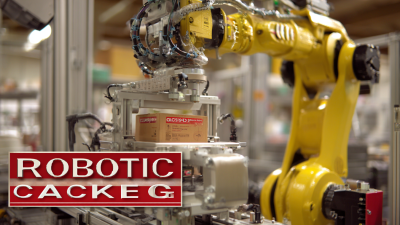

In the fast-evolving world of automation, the Robotic Case Packer has emerged as a pivotal solution. According to industry reports, the market for robotic packing solutions is expected to grow by 15% annually over the next five years. This surge highlights the increasing demand for efficiency in packaging processes. Companies are seeking more intelligent and adaptable solutions to optimize their operations.

Choosing the right Robotic Case Packer is crucial. Organizations must assess compatibility with existing systems. Data shows that businesses using advanced robotics reduce packaging costs by up to 20%. However, the selection process can be daunting, with numerous factors to consider. Common pitfalls include overlooking specific product types and neglecting scalability needs.

Many companies might rush their decisions, but haste often leads to regret. A well-informed choice involves balancing current specifications with future growth. Industry experts suggest taking the time to evaluate various models and technology. Success in automation hinges not just on initial investment but also on strategic alignment with overall operations.

Understanding the Basics of Robotic Case Packing Technologies

Robotic case packing technologies are transforming the packaging landscape. They offer precision and efficiency. Understanding the fundamentals is crucial for choosing the right solution.

When selecting a robotic case packer, consider the payload capacity. The weight of products can vary. Ensure the robot can handle your heaviest items. Look for flexibility in design. Robots should adapt to different case sizes easily.

It's essential to assess the system's compatibility with current processes. Robots need to integrate smoothly with existing equipment. This can sometimes be overlooked. Test the robotic system before full commitment. Observe its speed and precision in action.

Don’t forget about the support and training offered. Having good support can ease the transition. Training can help your team utilize the robot effectively. Reflect on your specific needs. Document what works and what doesn’t. Each facility has unique challenges, and a one-size-fits-all solution might fail.

Evaluating Production Needs and Facility Layout for Optimal Selection

When considering a robotic case packer, evaluating production needs is crucial. Understanding the types of products being handled can help determine the necessary features. For instance, if a facility handles diverse products, flexibility becomes essential. According to a 2021 industry report, 48% of manufacturers highlighted adaptability as a top consideration. If the robotic system cannot accommodate this, it's likely to fall short in efficiency.

Facility layout plays an equally important role. A streamlined workflow should minimize unnecessary movement and reduce bottlenecks. A report from the Association for Packaging and Processing Technologies emphasized that optimal layout can improve productivity by up to 30%. Space constraints can lead to poor equipment placement and may hinder performance over time. Cobbling together solutions often creates confusion, and inefficiencies linger if not addressed.

These considerations often present challenges. Facility managers may underestimate the impact of layout on robotic performance. Issues like inadequate power supply or unreachable areas complicate installation. It's vital to analyze these factors pre-purchase. Inadequate planning can result in unexpected delays and costs, which many have experienced firsthand. Balancing robotics with proper facility design takes careful thought and foresight.

Assessing Robotic Features and Specifications for Your Applications

When selecting a robotic case packer, focus on its features and specifications. Identify your packing needs based on product size and weight. A robotic case packer needs to adapt to different product types. Check if it can handle fragile items without damage. Some models may struggle with delicate packaging, which could lead to costly errors.

Evaluate the speed and precision of the robot. Each application requires specific throughput rates. If your production line is fast, opt for a model that can keep up. However, higher speed might reduce accuracy. Sometimes, the balance between speed and precision is tricky to find.

Consider the flexibility of the equipment. Can it be easily reprogrammed for new products? A robotic case packer with limited flexibility may become obsolete sooner. Maintenance and the availability of parts are equally important. Ensure the robot can be serviced without long delays. A lack of spare parts can halt production, causing issues down the line.

Considering Cost, ROI, and Maintenance Factors in Decision Making

When selecting a robotic case packer, considering cost, ROI, and maintenance is crucial. A recent report by the International Federation of Robotics states that automating packaging lines can reduce labor costs by up to 30%. This presents a compelling case for investment. However, upfront costs can be significant. Businesses should evaluate their budgets carefully. A robotic system may require a substantial initial outlay, but the long-term savings can be a game-changer.

ROI calculations are essential. Typically, companies see a return within three years. Sales growth often accelerates with faster packaging speeds. The automation also minimizes errors, which can lead to savings on waste and rework. However, businesses need to remember: not every process suits automation. An in-depth analysis of workflow is necessary. Sometimes, robotic solutions might not align perfectly with specific needs. For instance, high variability products could challenge robotic packers. Maintenance plays a vital role in overall cost management. Regular servicing is critical to prevent costly breakdowns. Skimping on maintenance can lead to unplanned downtimes. Balancing these factors is vital for making an informed decision.

Researching Vendors and Support Options for Long-Term Partnerships

When considering robotic case packers, it's crucial to research vendors and their support options. This exploration can lead to successful long-term partnerships. Look for companies that prioritize customer service. Responsive support can make a significant difference when problems arise.

One tip is to evaluate the vendor's track record. Look for reviews and case studies. These will give you insight into their reliability. Another important aspect is to examine training options. The right training can help your team operate the machines effectively. Don't overlook ongoing maintenance support. This is vital for ensuring the longevity of your investment.

Assess whether the vendor offers customization. Different operations have unique needs. A one-size-fits-all approach might not suit your line. A flexible vendor can adapt to your specific requirements over time. Keep in mind that not every vendor will meet your expectations. Take the time to ask questions and clarify details before making a commitment.

Top 10 Factors to Consider When Choosing a Robotic Case Packer

Related Posts

-

Unveiling the Best Robotic Case Packer with Impressive Specs and 5 Key Features

-

How to Optimize Container Packaging for Maximum Efficiency and Cost Savings

-

5 Essential Insights for Maximizing Efficiency with Case Packer Machines

-

Why Choose an Automatic Carton Sealing Machine for Your Packaging Needs

-

Navigating Global Standards for Food Packaging Machines: A Comprehensive Guide to Export Certification

-

How to Choose the Best Automatic Carton Sealing Machine for Your Packaging Needs