A-B-C Blog

Revolutionizing Your Production Line with Innovative Industrial Packing Machines

In today's competitive manufacturing landscape, efficiency and precision have become paramount for sustaining growth and meeting increasing consumer demands. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach USD 53.48 billion by 2027, growing at a CAGR of 3.5% from 2022. Among various technologies, the Industrial Packing Machine stands out as a transformative solution, enabling manufacturers to optimize their production lines and reduce operational costs. With advancements in automation and smart technologies, modern packing machines not only enhance productivity but also ensure the integrity and safety of products throughout the packaging process.

As innovations proliferate, businesses are recognizing the critical role that Industrial Packing Machines play in revolutionizing their production capabilities. These machines are designed to accommodate a wide range of products, from consumer goods to industrial supplies, with varying packaging requirements. The International Packaging Institute highlights the significance of investing in advanced packing technologies, noting that companies adopting such innovations can improve their throughput by 20-30% while minimizing waste. By integrating cutting-edge packing solutions, manufacturers can streamline their workflows and achieve greater sustainability, ultimately driving profitability and market competitiveness in a rapidly evolving industry.

The Impact of Industrial Packing Machines on Production Efficiency

In the fast-paced world of manufacturing, industrial packing machines play a crucial role in enhancing production efficiency. These machines streamline packaging processes, reduce labor costs, and minimize human error, allowing manufacturers to focus on their core operations. By automating the packing phase, businesses can significantly increase throughput, ensuring that products are packaged and shipped faster, thereby meeting customer demands and improving satisfaction.

The integration of advanced technologies, such as AI and Industry 4.0, further amplifies the impact of industrial packing machines on production efficiency. AI-driven systems can predict maintenance needs, optimize packing patterns, and even tailor packaging solutions to specific products. This adaptation not only boosts efficiency but also fosters resource conservation, such as reducing material waste and energy consumption. As a result, companies are better equipped to respond to market changes and enhance their competitive edge.

Moreover, innovations such as vacuum packing machines have emerged as essential tools in preserving product quality across various industries, particularly in food and pharmaceuticals. By extending shelf life and maintaining freshness, these machines contribute significantly to reducing spoilage and waste. As businesses continue to embrace these advanced packing technologies, the overall impact on productivity and sustainability will be profound, revolutionizing the way production lines operate in the coming years.

Impact of Industrial Packing Machines on Production Efficiency

Key Features to Look for in Innovative Packing Technologies

When considering innovative packing technologies for your production line, it's essential to focus on key features that can significantly enhance efficiency and productivity. First and foremost, automation is a game-changer in the packing industry. Advanced industrial packing machines equipped with automated systems can handle various packaging tasks, from filling and sealing to labeling and palletizing. This reduces the need for manual labor, minimizes human error, and speeds up the overall process, allowing businesses to meet higher demand without sacrificing quality.

Another crucial feature to look for in innovative packing technologies is flexibility. Modern packing machines should be able to accommodate a wide range of packaging materials and sizes, adapting to different products easily. This versatility ensures that companies can pivot quickly to market changes without needing to invest in multiple machines. Additionally, the ability to integrate with existing production systems can streamline operations, offering a seamless flow from manufacturing to packing.

Finally, sustainability is becoming an increasingly important factor in the selection of packing technologies. Innovative machines that use eco-friendly materials and reduce waste not only help companies meet environmental regulations but also appeal to consumers who prioritize sustainability. By investing in packing solutions that align with environmental goals, businesses can enhance their brand reputation while contributing positively to the planet.

Case Studies: Successful Transformations with Modern Packing Solutions

In today’s fast-paced manufacturing environment, the integration of innovative industrial packing machines can dramatically enhance efficiency and productivity on the production line. Several companies have successfully transformed their operations by adopting modern packing solutions tailored to meet their specific needs. Case studies of these transformations provide valuable insights into the immense benefits of embracing technology in packing processes.

One notable example is a leading beverage company that faced challenges with bottling and packaging speeds, leading to bottleneck situations during peak production times. By implementing a high-speed robotic packing system, they improved their throughput significantly. This innovative solution not only decreased labor costs but also minimized the risk of human error, ensuring the consistency and integrity of their packaging. The case highlights how investing in advanced packing technology can result in substantial operational improvements and cost savings.

Another compelling case involves a cosmetics manufacturer that struggled with varied package sizes and types, which complicated their packing processes. By introducing a flexible packing machine capable of handling different products without extensive reconfiguration, the company streamlined their operations. This machine's versatility allowed for quick adaptations to new product lines and seasonal promotions, thereby enhancing their market responsiveness. Such successful implementations underscore the power of modern packing solutions to transform production lines into agile, efficient systems that can better meet consumer demands.

Future Trends in Industrial Packing and Automation

The future of industrial packing is not just about efficiency; it’s about integrating innovative technologies that will shape the production landscape. As the world shifts towards automation, packing machines are evolving to incorporate advanced functionalities that enhance productivity and adapt to diverse market demands. With a growing emphasis on sustainable practices, industries are increasingly leaning towards smart packing solutions that minimize waste and maximize resource utilization, reflecting a significant trend toward greener manufacturing.

One of the pivotal trends driving this transformation is the fusion of automation and artificial intelligence in production lines. Manufacturers are investing in collaborative robots and autonomous mobile robots, streamlining logistics and reducing human error. The rise of smart packaging also signals a change; companies are adopting solutions that allow for real-time tracking and enhanced traceability, catering to consumer demand for transparency. As packaging becomes a crucial part of the supply chain, the need to innovate continues to grow.

Moreover, emerging markets are fueling the advancement of packaging technologies. As countries aim for increased production efficiency and economic resilience, the integration of advanced packing machines into their production lines is becoming a key strategy. Utilizing modular designs and versatile applications, these machines are set to revolutionize the packing process, ensuring that businesses remain competitive in an ever-evolving global market.

Revolutionizing Your Production Line with Innovative Industrial Packing Machines - Future Trends in Industrial Packing and Automation

| Technology | Benefits | Future Trends | Impact on Production |

|---|---|---|---|

| Robotic Packing Arms | Higher speed and accuracy | Increased integration with AI | Enhanced throughput and reduced errors |

| Smart Sensors | Real-time monitoring | Autonomous decision making | Minimized downtime |

| Automated Packaging Lines | Reduced labor costs | Customization to consumer needs | Greater flexibility in production |

| Eco-friendly Packaging Solutions | Sustainability | Increased regulatory compliance | Improved brand reputation |

| ERP Integration | Streamlined operations | Real-time data analytics | Optimized resource allocation |

How to Choose the Right Packing Machine for Your Production Needs

When it comes to optimizing your production line, selecting the right packing machine is pivotal. According to a report from MarketsandMarkets, the global packaging machinery market is expected to reach USD 66 billion by 2025, growing at a CAGR of 4.4%. With such rapid growth, manufacturers must carefully consider their operational needs and technological advancements when choosing the right equipment.

One key factor in selecting a packing machine is understanding the specific requirements of your production line. For instance, if your products vary in size and shape, look for machines that offer versatility, such as adjustable packing formats. A study published by Smithers Pira indicates that versatility in packaging can lead to a 15% boost in efficiency, as companies can easily adapt to changing market demands.

Furthermore, automation is becoming increasingly significant in the packaging industry. Research from Grand View Research highlights that automated packing solutions can reduce labor costs by up to 30% while enhancing production speed. Choosing a semi-automated or fully automated machine can dramatically streamline the packing process, ensuring consistency and reducing human error.

Lastly, consider the total cost of ownership beyond the initial purchase price. According to a report by PMMI, the Association for Packaging and Processing Technologies, maintenance costs can account for nearly 20% of the overall cost of ownership for packaging machinery. Investing in machines with longer life spans and better durability can help mitigate these costs in the long run. By aligning your packing machine choice with these considerations, you can significantly enhance the efficiency of your production line.

Revolutionizing Your Production Line: Packing Machine Efficiency

This bar chart illustrates the efficiency of different packing machines based on their output capacity (units per hour) and operational costs (USD). Choosing the right packing machine can significantly enhance your production line efficiency.

Related Video

-

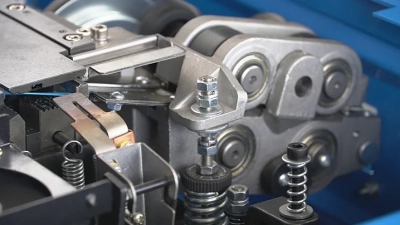

วิธีการปรับตั้งชุดลูกกลิ้ง แก้ปัญหาสายรัดออกมาเอง (ซ่อมเครื่องรัดกล่อง)

View: 39643Channel: WePackage -

Revolutionize Your Packaging with Factory Stand up Bag Pouch Making Machine

View: 504Channel: 1³ Machine -

Revolutionize Your Line with Advanced Filling Machines 🚀

View: 64Channel: Filling machine -shanghai paixie pack