A-B-C Blog

2026 Top Innovations in Pallet Stacking Machine Technology?

The pallet stacking machine industry stands on the brink of innovation. Experts predict advancements that could redefine efficiency. John Smith, a leading figure in automation, states, "The future of pallet stacking machines is about adaptability and intelligence." These machines are evolving, integrating AI for smarter operations.

Recent trends showcase significant improvements in design. Enhanced safety features are emerging, reducing workplace accidents. Companies are focusing on energy efficiency. However, challenges remain. High costs of advanced technology may deter small businesses. Moreover, the gap in knowledge about proper implementation needs to be addressed.

Innovations are vital, yet not every trend will succeed. Industry leaders must critically evaluate what truly benefits operations. As the pallet stacking machine market expands, reflecting on past mistakes will guide future decisions. Balancing ambition with practicality is essential. The journey of innovation is just beginning.

Emerging Trends in Pallet Stacking Machine Technology for 2026

The pallet stacking machine technology is evolving rapidly. In 2026, automation and AI integration will lead the charge. These innovations will improve efficiency and precision in warehouse operations. With smart sensors, machines will adapt to different types of pallets. This flexibility will reduce waste and save time.

Tips for implementing new technology: Always test equipment in a controlled environment first. Understand the learning curve for your staff. Seek feedback from your team regularly to address issues early.

Another emerging trend is the focus on sustainability. Environmentally friendly materials and energy-efficient designs will become standard. This shift will meet consumer demand for greener practices. However, consider the cost implications. Sometimes, cheaper alternatives may lead to higher long-term expenses. Ensure all investments align with your company’s values and goals.

Tips for sustainability: Conduct a thorough cost-benefit analysis before any change. Collaborate with experts to choose the best materials. Involve every department in the transition process for better adoption.

2026 Top Innovations in Pallet Stacking Machine Technology

| Innovation | Description | Benefits | Expected Impact |

|---|---|---|---|

| Automatic Height Adjustment | Machines that automatically adjust stacking heights based on pallet size. | Increased efficiency and reduced risk of damage. | Higher throughput and operational flexibility. |

| Smart Sensors Integration | Integration of IoT sensors for real-time monitoring and data collection. | Improved maintenance scheduling and reduced downtime. | Prolonged machine life and lower operational costs. |

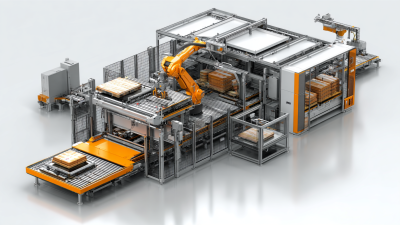

| Robotic Palletizers | Use of robotic arms for precise stacking of varied pallet loads. | Enhanced accuracy and speed in palletizing. | Lower labor costs and improved safety. |

| Energy Efficiency Solutions | Machines designed to consume less power, incorporating green technology. | Cost savings on energy bills and reduced carbon footprint. | Contributes to sustainability goals. |

| Modular Stacking Systems | Customizable modules that can be adjusted or replaced as needed. | Scalability and flexibility to adapt to changing needs. | Future-proofing operations. |

Key Innovations Enhancing Efficiency in Pallet Stacking Operations

In 2026, pallet stacking machine technology is evolving rapidly. Key innovations focus on enhancing efficiency and safety. Automated systems are becoming standard. They reduce human error and improve productivity. These machines use advanced sensors to optimize stacking patterns. This minimizes space and maximizes load capacity.

Implementing smart algorithms plays a crucial role. They analyze data in real-time. As a result, businesses can adjust stacking processes instantly. Predictive maintenance helps detect issues before they escalate. Downtime is significantly reduced, ensuring smooth operations.

Tips: Train your staff on new technologies. A well-informed team is essential for success. Regularly review stacking patterns for optimal performance. Consistent evaluation leads to better outcomes. Keep an eye on emerging trends. Adaptability is key in this fast-changing industry. Reflect on performance regularly to identify areas for growth.

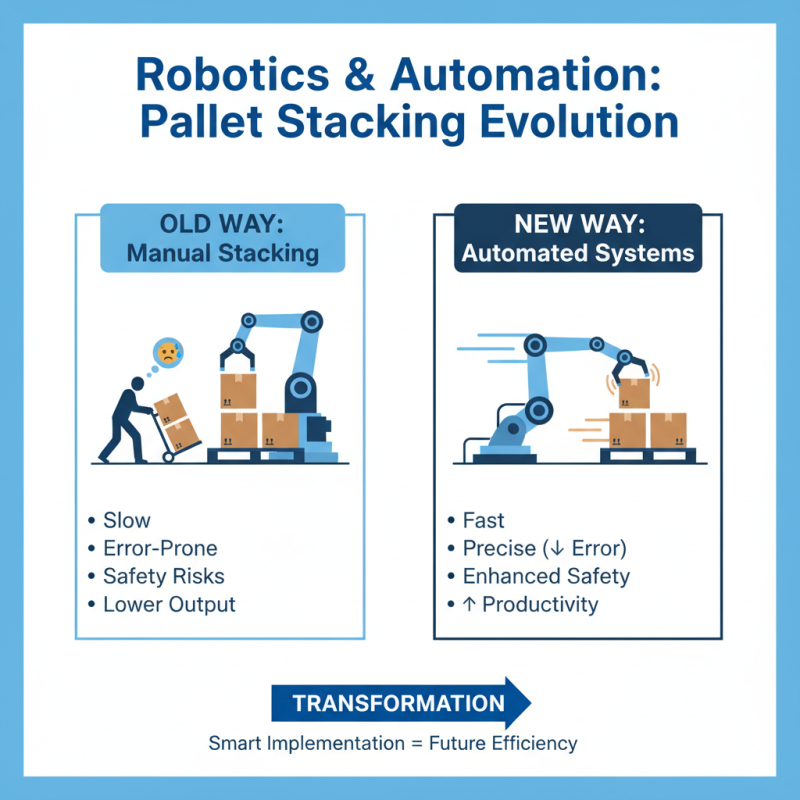

Impact of Robotics and Automation on Pallet Stacking Machines

Robotics and automation are transforming pallet stacking machines. These technologies improve efficiency and safety in warehouses. Automated systems can stack pallets with precision, reducing human error. They operate faster than manual methods, which can increase overall productivity. However, implementing these systems requires careful thought.

The integration of robotics can face challenges. Workers may feel uncertain about job security. Adaptation to new technology can be overwhelming for some. Training is essential but can be time-consuming. Companies need to invest in their workforce alongside technology. Balancing automation and human labor is critical.

Data management plays a key role in this transition. Smart pallet stacking machines collect data on stacking patterns and inventory levels. This information helps optimize processes. Yet, relying heavily on data can lead to issues if the data is incorrect or misinterpreted. Companies must continually assess their systems to prevent potential pitfalls. Reflecting on both benefits and drawbacks is important for sustainable growth.

Sustainability Features in 2026 Pallet Stacking Technologies

The 2026 innovations in pallet stacking machine technology focus heavily on sustainability. With growing environmental concerns, companies are turning to eco-friendly solutions. Electric-powered machines are becoming more common. They reduce carbon emissions significantly compared to diesel alternatives. The shift to renewable energy sources in production is also gaining traction.

Implementing recyclable materials in machine construction is a key trend. For instance, frames made from aluminum and other recycled components enhance durability. This approach not only helps the planet but also improves the overall efficiency of the machines. Users can expect lower energy consumption in the long run.

Tips: Always consider energy efficiency when selecting equipment. Look for certifications that indicate lower environmental impact. It's also wise to monitor usage patterns. Adjustments in operational strategies can lead to substantial savings and reduced waste. Improving these practices requires ongoing evaluation and adjustments. Continuous feedback is essential for sustainable practices.

Future Challenges and Solutions in Pallet Stacking Machine Design

The design of pallet stacking machines faces numerous challenges in their evolution. One major issue is space limitation. As industries work to optimize warehouse layouts, machines must adapt. Smaller, more efficient machines are crucial. They must offer the same stacking capabilities while fitting into tighter spaces.

Automation presents another challenge. Many designs are outdated, relying on manual controls. This can lead to inefficiencies. Incorporating AI and advanced sensors can improve operations. However, integrating these technologies complicates design processes. Engineers must ensure safety and reliability without compromising performance.

Tips: When considering new designs, keep adaptability in mind. Future machines must work seamlessly in evolving environments. Focus on user-friendly interfaces. Make them easy to operate for all staff levels.

Finally, sustainability is a growing concern. Machines should use energy-efficient components and recyclable materials. Balancing performance with eco-friendliness is essential. Innovations should not sacrifice environmental impact for productivity. As these challenges arise, continued research and development will be key in creating the next generation of pallet stacking machines.

Related Posts

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Pallet Dispenser for Your Business

-

Understanding the Benefits of Using a Pallet Dispenser for Your Warehouse Operations

-

Revolutionizing Your Production Line with Innovative Industrial Packing Machines

-

The Complete Guide to Mastering Food Packaging Machine Selection and Usage

-

Understanding the Challenges Faced by Depalletizer Machines in Modern Warehousing

-

Mastering the Art of Containers and Packaging Strategies for Sustainable Business Growth