A-B-C Blog

Understanding the Benefits of Wrap Around Case Packer Technology in Modern Packaging Solutions

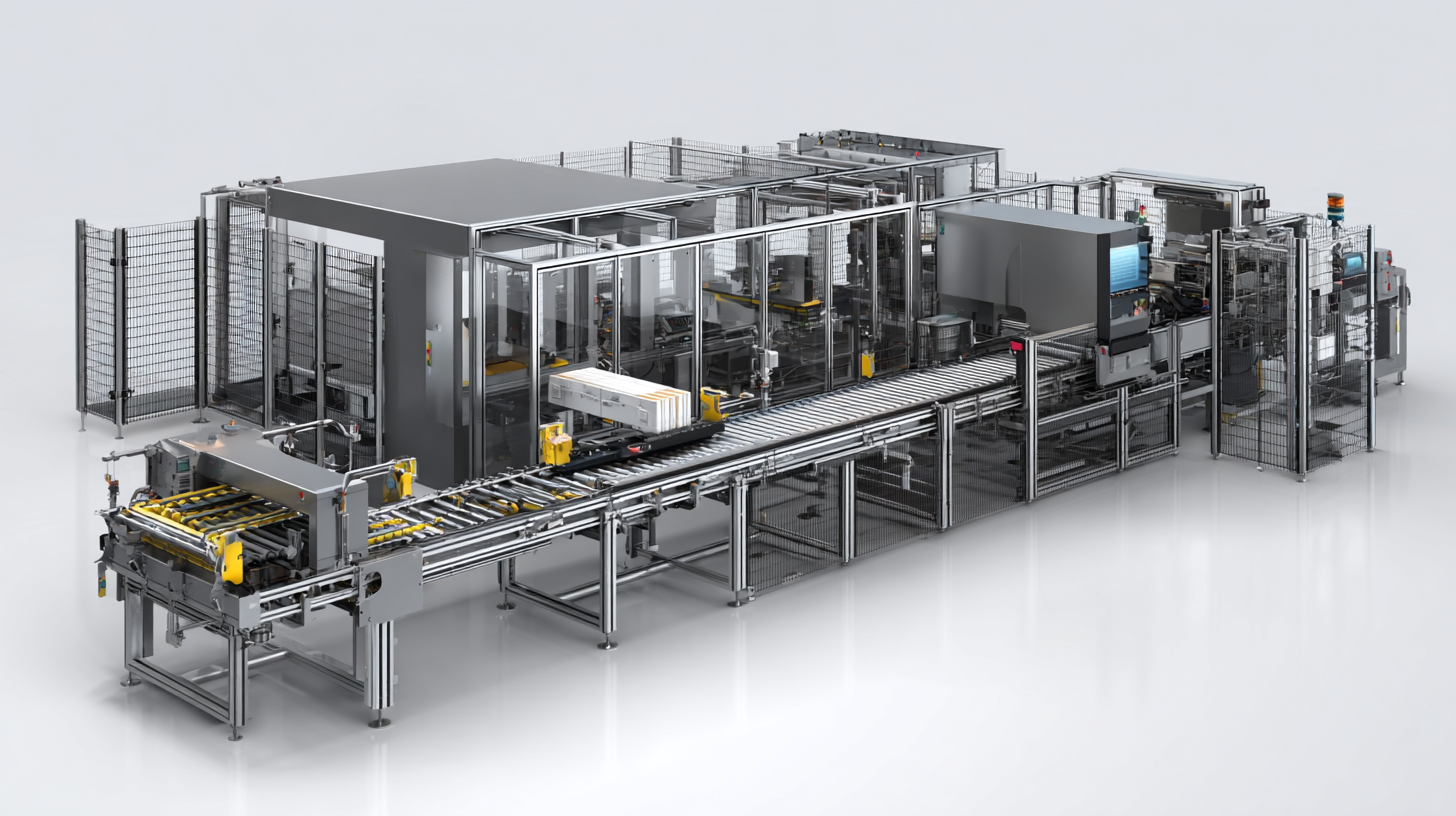

In the ever-evolving landscape of modern packaging solutions, the "Wrap Around Case Packer" technology has emerged as a transformative force, streamlining packaging processes and enhancing operational efficiency. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $46.3 billion by 2024, with automated solutions like Wrap Around Case Packers driving significant growth due to their ability to reduce labor costs and increase production rates. Additionally, a study by the Packaging Machinery Manufacturers Institute (PMMI) indicates that nearly 60% of companies are prioritizing automation to meet the demands of high-speed production and sustainability goals. As consumer preferences shift towards convenient and eco-friendly packaging, the Wrap Around Case Packer stands out for its versatility, allowing for efficient packing of various products while minimizing material waste. This introduction sets the stage to explore the multitude of benefits that this advanced technology offers, positioning it as a crucial component in modern packaging strategies.

The Evolution of Case Packer Technology in Modern Packaging

The evolution of case packer technology has significantly transformed modern packaging solutions, particularly in the meat and pharmaceutical industries. Over the past 25 years, advancements have led to increased efficiency, safety, and productivity, allowing businesses to meet growing consumer demands. Reports indicate that the case packers market is projected to grow significantly from 2024 to 2032, reflecting the accelerating need for streamlined packaging processes across various sectors. With technological innovations, manufacturers can achieve faster output and consistent product quality, essential in high-demand environments such as frozen pizza production.

To fully leverage the benefits of these advancements, companies should consider investing in automated systems that enhance packaging accuracy and reduce labor costs. According to industry forecasts, the global packer bottle market alone is expected to reach $73.5 billion by 2030, driven by innovations that prioritize sustainability and efficiency. Adopting these modern technologies not only meets regulatory standards but also aligns with shifting consumer expectations for quality and environmentally friendly products.

**Tip:** When transitioning to new case packer technologies, conduct thorough research on market trends and invest in scalable solutions to accommodate future growth. Keeping abreast of technological advancements can significantly impact operational efficiency and customer satisfaction.

Understanding the Benefits of Wrap Around Case Packer Technology in Modern Packaging Solutions

| Feature | Description | Benefits |

|---|---|---|

| Speed | Wrap around case packers can quickly pack products at high speeds. | Increased productivity and efficiency in the packaging process. |

| Flexibility | These machines can handle various product sizes and shapes. | Ability to adapt to different production needs without extensive reconfiguration. |

| Sustainability | Designed for minimal material waste, using eco-friendly materials. | Reduced environmental impact and lower costs for materials. |

| User-Friendly | Intuitive controls and easy maintenance features. | Lower training costs and reduced downtime. |

| Compact Design | Space-efficient design suitable for various factory layouts. | Saves floor space and allows for better utilization of production areas. |

Key Advantages of Wrap Around Case Packers for Efficiency and Productivity

The rise of wrap around case packers has revolutionized modern packaging solutions, contributing significantly to efficiency and productivity. One of the key advantages of this technology is its versatility, allowing businesses to handle various product sizes and shapes without the need for extensive retooling. This adaptability not only streamlines production lines but also reduces downtime, enabling manufacturers to respond swiftly to changing market demands.

Tips for optimizing your wrap around case packer include:

- Conducting regular maintenance checks to ensure all components are functioning optimally.

- Training your staff on best practices for loading products to minimize errors and improve packing speed.

Implementing these measures can help maintain high productivity levels and reduce waste associated with mispackaging.

Another significant advantage of wrap around case packers is their sustainability. Using fewer materials compared to traditional packaging methods, these systems help lower overall costs both in raw materials and shipping. By adopting these eco-friendly practices, companies can enhance their corporate responsibility while improving their bottom line.

Cost-Effectiveness: How Wrap Around Case Packers Reduce Packaging Expenses

Wrap Around Case Packer technology has emerged as a game-changer in the packaging industry, particularly in terms of cost-effectiveness. Recent industry reports, such as those from Mordor Intelligence, highlight that modern packaging solutions using automated systems can significantly reduce labor costs by upwards of 30%. This reduction is achieved through the streamlined application of packaging materials, which minimizes the need for manual intervention. Furthermore, a study by Smithers Pira indicates that investing in automated case packers can lead to a return on investment within 18 months due to these cost savings.

In addition to labor reductions, wrap around case packers optimize material usage, leading to decreased packaging expenses. According to a 2022 report by Packaging Strategies, companies utilizing wrap-around technology have reported a 15% reduction in packaging materials, which in turn minimizes their environmental footprint and waste. This efficiency not only contributes to lower costs but also aligns with the increasing consumer demand for sustainable practices. By implementing wrap around case packing, businesses not only enhance their bottom line but also bolster their reputation in the market as environmentally conscious entities.

Flexibility and Customization: Adapting to Diverse Packaging Needs

Wrap around case packer technology has transformed the packaging landscape by offering unparalleled flexibility and customization to meet diverse packaging needs. This innovative approach allows manufacturers to configure packaging solutions that adapt seamlessly to various product shapes, sizes, and materials. With the ability to handle a wide range of products—from fragile glass containers to robust aluminum cans—wrap around case packers can be tailored to optimize the packaging process while maintaining product integrity.

Furthermore, the customization options available with wrap around case packers enable businesses to implement specific branding and design requirements effectively. Companies can easily change graphics, colors, and formats to align with their brand aesthetics or seasonal promotions without extensive downtime or costly retooling. This adaptability not only enhances operational efficiency but also allows brands to respond nimbly to market trends and consumer preferences. As a result, manufacturers can maintain a competitive edge in today’s fast-paced market, ensuring that their packaging solutions meet both functional and promotional needs.

Sustainability in Packaging: The Eco-Friendly Benefits of Wrap Around Case Packers

Wrap around case packing technology is increasingly recognized for its eco-friendly advantages in modern packaging solutions. This innovative method utilizes minimal materials while maximizing efficiency, often reducing the environmental footprint of packaging processes. The design allows for the use of recyclable materials, ensuring that the packages can be repurposed rather than ending up in landfills. By placing products into cases without excess materials or complicated structures, companies can significantly decrease the waste generated during packaging.

Related Posts

-

Finding Quality Suppliers for Best Wrap Around Case Packers Essential Checklist for Global Buyers

-

Navigating Trends and Innovations in Package Machine Industry at 2025 China Import and Export Fair

-

Advantages of Using Box Taping Machines for Efficient Packaging Solutions

-

Navigating Global Standards for Food Packaging Machines: A Comprehensive Guide to Export Certification

-

Exploring Packaging Innovation: Highlights from the Record-Breaking 137th Canton Fair

-

How to Choose the Right Bottom Case Sealer for Your Business Needs