A-B-C Blog

How to Choose the Best Case Erector Machine for Your Packaging Needs

In today's fast-paced manufacturing environment, the efficiency of packaging processes is critical for maintaining competitiveness. The global packaging market is projected to reach USD 1 trillion by 2024, with a significant increase in demand for automation solutions, especially Case Erector Machines. These machines not only streamline the process of assembling boxes but also enhance overall production lines' speed and efficiency.

According to recent industry reports, the adoption of case erectors can reduce labor costs by up to 50% while improving accuracy and consistency in packaging. As businesses seek to optimize their operations, understanding how to choose the best Case Erector Machine tailored to specific packaging needs becomes increasingly essential. This blog will guide you through the key factors to consider when selecting the most suitable model for your production line.

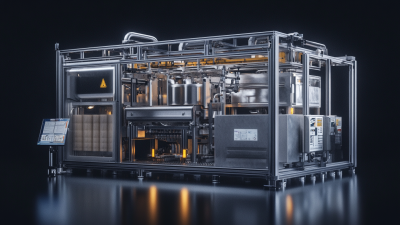

Understanding Different Types of Case Erector Machines for Packaging Solutions

When selecting a case erector machine for your packaging needs, understanding the different types available is crucial for optimizing efficiency and cost-effectiveness. Case erector machines generally fall into three main categories: automatic, semi-automatic, and manual. According to a recent industry report by IBISWorld, the demand for automatic case erectors has been rising, with the market projected to grow at a rate of 5.4% annually over the next five years. These machines are ideal for high-volume production environments where speed and accuracy are paramount.

Tip: Consider the size and shape of your products when choosing a case erector. Specific models are designed for various box styles, including regular slotted containers (RSC) and tray styles. Ensuring compatibility can significantly reduce downtime and increase productivity.

Semi-automatic case erectors remain a popular choice for medium-sized operations, providing a balance between speed and manual input. Businesses that utilize these machines reported a 30% increase in efficiency, as noted in a 2023 Packaging Machinery Manufacturers Institute (PMMI) report. These systems also allow for flexibility, accommodating different box sizes with minimal setup changes.

Tip: Evaluate the machine's ease of operation and maintenance requirements. Investing in user-friendly machinery can limit training time and enhance overall output.

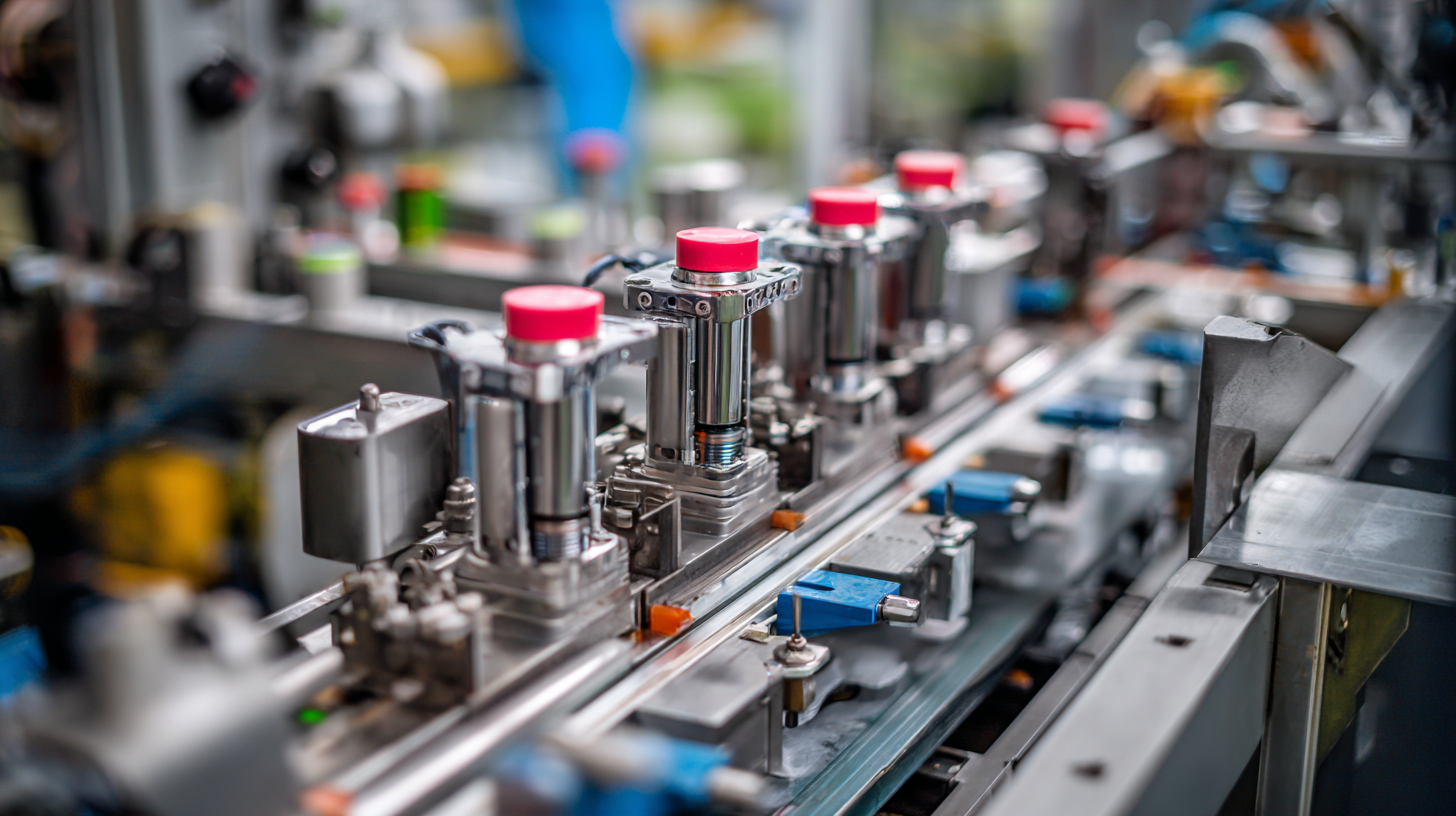

Key Features to Consider When Choosing a Case Erector Machine

When selecting a case erector machine, it's essential to weigh several key features that can significantly influence your packaging operations. First, consider the machine's speed and efficiency. In today's competitive market, a reliable case erector that can operate continuously—24/7—is critical for maintaining productivity and meeting demand. Look for machines that are not only fast but also designed for seamless integration into your current production line.

Next, examine the machine's flexibility and adaptability. The ability to handle various box sizes and styles without extensive reconfiguration can save both time and labor costs. As packaging needs evolve, having a case erector that can accommodate changes will help to future-proof your operations. Additionally, pay attention to the automation features available, such as the incorporation of robotics, which can further enhance efficiency and reduce manual handling.

Lastly, it's prudent to evaluate the machine's maintenance and support options. A quality case erector should come with robust customer support and easy access to spare parts, ensuring that downtimes are minimized and your production continues smoothly. By carefully assessing these attributes, businesses can make informed decisions that align with their packaging goals in 2024 and beyond.

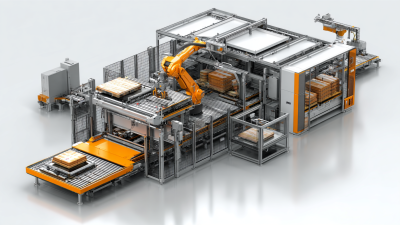

Evaluating Production Speed and Efficiency of Case Erector Machines

When selecting a case erector machine, production speed and efficiency are crucial factors to consider. The machine's speed, often measured in cases per minute, directly impacts your overall throughput. An efficient case erector not only meets current production demands but also allows for scalability as your business grows. Look for machines that offer adjustable speeds, enabling you to optimize performance based on varying operational needs or product specifications.

In addition to speed, the efficiency of a case erector machine can be evaluated through its design and ease of use. Machines that minimize downtime through quick changeovers or require less maintenance help maintain a steady production flow. Features such as automatic case feeding, compact design, and user-friendly controls contribute significantly to operational efficiency. Assessing these features in conjunction with production speed will enable businesses to choose a case erector that aligns with their packaging needs while maximizing productivity and reducing costs.

Production Speed and Efficiency of Case Erector Machines

Budgeting for Your Case Erector Machine: Costs and ROI Considerations

When budgeting for a case erector machine, it’s essential to consider not just the initial purchase cost but also the long-term return on investment (ROI). Calculate the total cost of ownership, which includes installation, maintenance, and operation costs over the machine’s lifespan. This approach gives you a clearer picture of how the machine fits into your budget and its potential to enhance your productivity.

In evaluating ROI, consider the efficiency gains and labor savings that a case erector machine can provide. By automating the process of case forming, you reduce manual labor costs and minimize the risk of human error. Additionally, faster production times can lead to greater output, allowing your company to meet demand effectively. Analyze the payback period—how long it will take for the savings generated by the machine to cover its costs. A well-chosen case erector not only streamlines your packaging process but can also significantly improve your bottom line.

How to Choose the Best Case Erector Machine for Your Packaging Needs - Budgeting for Your Case Erector Machine: Costs and ROI Considerations

| Machine Type | Initial Cost ($) | Operating Cost/Year ($) | Production Speed (cases/hour) | Return on Investment (ROI, %) |

|---|---|---|---|---|

| Entry-Level Case Erector | $25,000 | $5,000 | 10 | 20% |

| Mid-Range Case Erector | $50,000 | 8,000 | 30 | 35% |

| High-End Case Erector | $100,000 | 10,000 | 60 | 50% |

| Custom Case Erector | $75,000 | 7,500 | 40 | 40% |

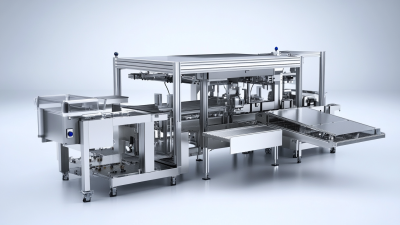

Assessing Space Requirements and Footprint for Case Erector Installation

When selecting the best case erector machine for your packaging needs, understanding the space requirements and footprint for installation is crucial. Case erectors vary significantly in size, and the chosen model must fit within the operational layout of your facility. According to a recent study by Packaging Machinery Manufacturers Institute (PMMI), up to 30% of packaging line efficiency can be lost due to improper equipment placement. This emphasizes the importance of evaluating not just the size of the machine but how it integrates into your current workflow.

Additionally, consider the layout of your facility. A well-planned installation can minimize downtime and enhance productivity. The same PMMI report highlights that an efficient floor plan can improve throughput by 15%. Therefore, businesses should measure available space carefully, accounting for additional room needed for maintenance and operation. Some machines require more clearance for adjustments and repairs, which can further influence your decision. Selecting a machine that fits your space constraints and operational flow can lead to significant long-term savings and efficiency improvements in your packaging processes.

Related Posts

-

Envisioning Tomorrow: The Evolution of Case Erector Machines in Packaging Industries

-

Navigating Global Standards for Food Packaging Machines: A Comprehensive Guide to Export Certification

-

Comprehensive Insights on Industrial Packaging Machines for Global Buyers

-

Understanding the Challenges Faced by Depalletizer Machines in Modern Warehousing

-

Mastering the Setup of the Best Automatic Carton Sealing Machine for Optimal Efficiency

-

Top 10 Palletizing Equipment Manufacturers from China at the 137th Canton Fair