A-B-C Blog

How to Choose the Right Bottom Case Sealer for Your Business Needs

In the fast-paced world of packaging, choosing the right Bottom Case Sealer can significantly impact operational efficiency and cost-effectiveness. According to a report by Smithers Pira, the global packaging machinery market is projected to reach USD 50 billion by 2025, with automated sealing solutions playing a critical role in this growth. As businesses seek to enhance throughput and maintain high product quality, understanding the various types of Bottom Case Sealers available—such as semi-automatic and fully automatic models—becomes paramount. Additionally, the right sealer can reduce material waste by ensuring precise sealing, which not only saves costs but also aligns with sustainability goals.

This guide will provide essential tips and insights to help you navigate the complexities of selecting the best Bottom Case Sealer tailored to your business needs, ensuring both efficiency and reliability in your packaging operations.

Key Factors to Consider When Selecting a Bottom Case Sealer for Your Operations

When selecting a bottom case sealer for your operations, several key factors should be considered to ensure you choose the right machine for your specific needs. First and foremost, evaluate the types of cases you need to seal. Different sealers operate best with specific case dimensions and weights. A machine designed for lightweight cardboard boxes may not efficiently handle heavier, bulkier cases. Identifying the range of case sizes your business typically uses is crucial to select a compatible sealer.

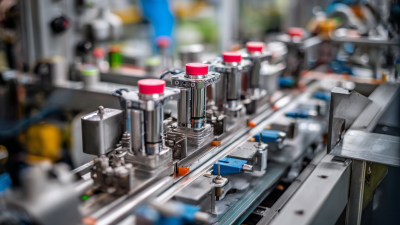

Another significant factor is the sealing method. There are various sealing techniques, such as tape sealing and hot melt glue sealing, and each has its advantages depending on your operational needs. For example, tape sealers are ideal for quick applications and versatile packaging, while hot melt glue sealers provide stronger, more tamper-proof seals. Assessing the speed and volume of production is also essential, as you’ll want a sealer that can keep up with your packaging line’s pace without compromising on quality. Considering these factors will help ensure a smooth transition to your new bottom case sealer, enhancing efficiency in your operations.

How to Choose the Right Bottom Case Sealer for Your Business Needs

| Feature | Description | Importance Level |

|---|---|---|

| Seal Type | Hot melt, pressure-sensitive, or water-based adhesives based on product needs. | High |

| Speed | Output rate in cases per minute to match production pace. | Medium |

| Adjustability | Ability to handle different box sizes and styles. | High |

| Durability | Construction quality for long-term performance. | High |

| Maintenance | Ease of cleaning and availability of replacement parts. | Medium |

| Cost | Initial investment and total cost of ownership. | High |

| Automation Level | Manual, semi-automatic, or fully automatic systems. | Medium |

Understanding Different Types of Bottom Case Sealers and Their Applications

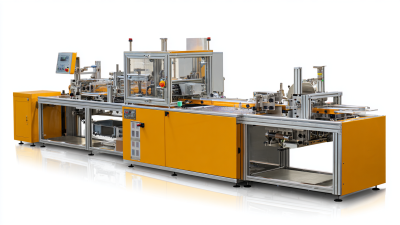

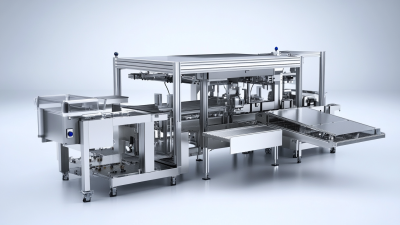

When selecting the right bottom case sealer for your business, it's essential to understand the various types available and their specific applications. Bottom case sealers primarily fall into two categories: manual and automatic. According to a report by Technavio, the global packaging machinery market, including case sealers, is expected to grow by USD 3.5 billion from 2021 to 2025, driven by the increasing demand for automated solutions in packaging processes. Manual sealers are ideal for small-scale operations or businesses that have varying case sizes, while automatic sealers are designed for high-speed production lines, offering efficiency and consistency.

Different industries utilize bottom case sealers in distinct ways. For example, food and beverage companies often require high-speed sealing options to maintain freshness and extend shelf life. A study by PMMI indicates that 60% of food and beverage manufacturers prioritize packaging automation to enhance productivity and reduce labor costs. On the other hand, e-commerce businesses may prefer versatile sealers that can accommodate multiple box sizes and handle return processes seamlessly. Understanding these industry-specific requirements will aid in selecting the right bottom case sealer tailored to your operational needs.

Essential Features to Look for in a Bottom Case Sealer

When selecting a bottom case sealer, it's crucial to consider several essential features that align with your business needs. According to a recent report by the Packaging Machinery Manufacturers Institute (PMMI), automated case sealers can boost packaging efficiency by up to 40%. First, look for a sealer that offers adjustable height and width settings, allowing for quick changeovers between different box sizes. This flexibility not only improves operational efficiency but also minimizes downtime, which can cost businesses an average of $22,000 per hour, as highlighted in industry assessments.

Another critical feature to examine is the consistency and reliability of the sealing mechanism. A high-quality bottom case sealer should provide uniform sealing pressure to ensure package integrity, especially for businesses in the food and beverage sector, which adhere to stringent safety standards. The Food and Drug Administration (FDA) found that improper sealing can lead to up to 15% product spoilage during shipping. Investing in a robust machine that utilizes advanced adhesive technologies can significantly reduce these risks, ensuring your products reach customers intact and compliant with regulations.

Cost vs. Efficiency: Finding the Right Balance in Bottom Case Sealers

When selecting a bottom case sealer for your business, the balance between cost and efficiency is crucial. Investing in a sealer that seems affordable upfront may lead to higher long-term expenses if it fails to meet your production demands. Conversely, a high-end model can enhance productivity and reduce labor costs but may be a financial stretch for smaller operations. Understanding your specific needs and production volume is essential in deciding which model offers the best value.

Efficiency in sealing processes plays a significant role in determining overall production capabilities. A sealer that operates smoothly and quickly can drastically reduce downtime and increase throughput. It's important to analyze the speed requirements of your packing line and ensure that the chosen sealer can keep pace without sacrificing quality. Additionally, incorporating advanced features, such as adjustable settings and automation, can improve operational efficiency, making the investment worth it despite a higher upfront cost. Ultimately, finding the right balance between cost and efficiency will help your business thrive in a competitive market.

Maintenance and Support: Ensuring Longevity of Your Bottom Case Sealer

When selecting a bottom case sealer for your business, understanding the maintenance and support required to ensure its longevity is paramount. According to a recent industry report by the Packaging Machinery Manufacturers Institute (PMMI), improper maintenance can lead to equipment downtime, costing businesses up to $20,000 per day in lost productivity. Regular maintenance schedules, including cleaning and lubrication checks, can significantly extend the life of a bottom case sealer. The report emphasizes that proactive maintenance increases the reliability of the equipment, ensuring consistent performance during peak production times.

Moreover, choosing a manufacturer that offers robust support services can enhance the lifespan of your sealer. A study from Packaging Digest highlighted that businesses with access to dedicated technical support experience a 30% reduction in equipment failure rates. This underscores the importance of selecting a vendor that provides comprehensive training, timely repairs, and routine inspections as part of their support services. By prioritizing maintenance and support, businesses can not only improve the operational efficiency of their bottom case sealers but also achieve a greater return on investment over time.

Related Posts

-

Ultimate Guide to Choosing the Best Bottom Case Sealer for Your Packaging Needs

-

Comprehensive Insights on Industrial Packaging Machines for Global Buyers

-

Revolutionizing Your Production Line with Innovative Industrial Packing Machines

-

Innovative Applications of Best Bottom Case Sealer in Global Packaging Solutions

-

Unmatched Quality in Global Export of Premium Industrial Packing Machines Made in China

-

How to Choose the Best Case Erector Machine for Your Packaging Needs