A-B-C Blog

Why Choose an Automatic Carton Sealing Machine for Your Packaging Needs

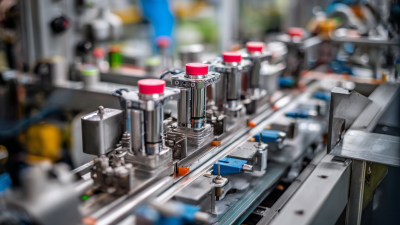

In the ever-evolving landscape of packaging technology, the importance of efficiency and reliability cannot be overstated. As businesses strive to optimize their production lines, the adoption of specialized machinery has become paramount. One such innovation making waves in the industry is the Automatic Carton Sealing Machine. According to Dr. Emily Thompson, a leading expert in packaging automation, "Investing in an Automatic Carton Sealing Machine is not just about keeping up with the competition; it’s about redefining your operational capabilities for greater profitability and efficiency."

The Automatic Carton Sealing Machine offers a seamless solution to meet the packaging needs of modern businesses. By automating the sealing process, companies can significantly reduce labor costs and minimize human error, leading to an overall faster production line. In an age where speed and precision are crucial, this machinery provides the perfect balance of reliability and efficiency. As industries evolve, the integration of such advanced technologies becomes essential for those looking to maintain a competitive edge.

In summary, choosing an Automatic Carton Sealing Machine is a strategic decision that can transform packaging operations. It allows businesses to not only streamline processes but also enhance the quality of their packaging. With experts advocating for its widespread adoption, it is clear that the future of packaging lies in automation, marking a pivotal shift in how products are sealed and delivered to consumers.

Benefits of Using an Automatic Carton Sealing Machine in Packaging

An automatic carton sealing machine offers numerous advantages that can significantly enhance packaging operations. One of the primary benefits is increased efficiency. These machines are designed to seal cartons quickly and consistently, reducing the time required for manual sealing processes. This not only speeds up production lines but also allows companies to allocate their labor resources to other critical tasks, ultimately improving overall productivity.

Additionally, automatic carton sealing machines ensure higher accuracy and consistency in sealing quality. Manual sealing can lead to variations in closure strength and application, which may compromise the integrity of the packaged product. In contrast, automated machines apply uniform seals, minimizing the risk of leakage or damage during transportation. This consistency not only enhances the safety of the products but also boosts customer satisfaction by delivering reliable packaging solutions.

Finally, using an automatic carton sealing machine can lead to cost savings over time. While the initial investment may be higher than manual alternatives, the long-term benefits of reduced labor costs, minimized material waste, and increased throughput often outweigh the upfront expenses. By streamlining packaging processes and improving overall operational efficiency, businesses can achieve a better return on investment and enhance their competitive edge.

Key Features to Look for in an Automatic Carton Sealing Machine

When considering an automatic carton sealing machine for your packaging needs, certain key features can significantly enhance efficiency and effectiveness. Firstly, look for machines that offer adjustable height settings and versatile widths to accommodate various carton sizes. This adaptability allows the machine to handle different packaging formats without requiring extensive modifications, streamlining your production process.

Another important feature is the sealing method employed by the machine. Machines that utilize both adhesive tape and hot melt glue systems provide flexibility in packaging options. Additionally, consider models equipped with advanced sensors that detect carton presence, ensuring a seamless and automatic sealing process. This reduces operational downtime and enhances productivity by minimizing manual intervention.

Lastly, durability and ease of maintenance are crucial factors. Select a machine built from robust materials to withstand continuous use in a busy production environment. Furthermore, a design that facilitates quick access to components for maintenance ensures minimal disruption during upkeep. By focusing on these key features, you can select an automatic carton sealing machine that meets your packaging requirements while enhancing overall operational efficiency.

Comparing Automatic vs. Manual Carton Sealing Solutions

When it comes to choosing a carton sealing solution, the choice between automatic and manual methods significantly impacts efficiency and productivity. Manual carton sealing, while cost-effective initially, often presents challenges in consistency and speed, particularly in high-volume environments. Operators must repeatedly engage in sealing tasks, which can lead to fatigue, errors, and inconsistent sealing quality. This approach may slow down production lines and can lead to increased labor costs in the long run.

In contrast, automatic carton sealing machines are designed to streamline the packaging process, offering several advantages over their manual counterparts. These machines can operate at high speeds, sealing multiple cartons per minute with precision and consistency. This not only reduces the risk of human error but also allows for continuous operation, minimizing downtime. With advanced technology, automatic sealers can be easily adjusted to accommodate various carton sizes, ensuring versatility without sacrificing performance. As businesses strive for efficiency, the transition to automatic sealing solutions becomes an increasingly attractive option to meet growing packaging demands.

How an Automatic Carton Sealing Machine Enhances Efficiency and Safety

An automatic carton sealing machine significantly enhances operational efficiency by streamlining the packaging process. By automating the sealing of cartons, businesses can reduce manual handling and minimize the time spent on each packaging task. This technology allows for consistent and rapid sealing, accommodating high volumes of products in a shorter timeframe. By eliminating the variations that come with manual sealing, companies can achieve uniformity, ensuring that every carton is sealed to the same standard, thus reducing the likelihood of errors that could lead to product damage during transport.

Safety is another critical aspect improved by the use of automatic carton sealing machines. Automation minimizes the risk of workplace injuries associated with repetitive manual tasks, such as cutting and sealing. Workers can focus on more strategic roles rather than the monotonous sealing process, which can lead to fatigue and accidents.

Additionally, many machines come equipped with safety features that protect operators from moving parts, further enhancing the overall safety of the packaging environment. This not only fosters a safer workplace but also contributes to employee well-being and retention.

Cost Considerations for Investing in an Automatic Carton Sealing Machine

Investing in an automatic carton sealing machine can significantly impact your packaging process, particularly in terms of cost efficiency.

Initially, businesses may be apprehensive about the upfront investment required for such machinery. However, the long-term savings and productivity gains often outweigh the initial outlay.

By automating the sealing process, companies can reduce labor costs, minimize material waste, and improve throughput, leading to a faster return on investment.

The machine’s reliability in achieving consistent seals reduces the likelihood of product returns or damages during shipping, ultimately safeguarding the company’s bottom line.

Moreover, automatic carton sealing machines often come with advanced features that allow for adaptability to different packaging requirements.

This versatility means businesses can scale their operations without the need for frequent equipment upgrades, further enhancing cost-effectiveness.

Regular maintenance and potential energy savings also contribute to lower operational costs over time.

Therefore, when evaluating the financial implications of acquiring an automatic carton sealing machine, it's essential to consider not only the initial purchase price but also the

savings generated through improved efficiency, reduced labor needs, and long-term reliability in the packaging process.

Related Posts

-

Unlocking the Future of Beverage Packaging Machines in 2025 with Innovative Technologies and Strategies

-

Global Quality Packaging Solutions Empowering International Trade from China

-

Advantages of Using Box Taping Machines for Efficient Packaging Solutions

-

How to Choose the Best Case Erector Machine for Your Packaging Needs

-

The Ultimate Guide to Choosing the Right Pallet Dispenser for Your Business Needs

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Pallet Dispenser for Your Business