A-B-C Blog

5 ways to get better case sealing

Square, securely sealed cases are more important than ever, as end users and ecommerce giants set new rules for CPG compliance.

But how can you get more from your case sealing operation?

We've identified 5 key factors you can manage in selecting or upgrading your case sealing equipment.

With these under control, you can deliver consistently high quality cases and improve your case sealing line productivity.

A-B-C's production-proven features deliver superior case sealing performance:

A-B-C case sealers utilize exclusive features to address 5 important case sealing factors, giving you consistent, reliable sealing and square, well-sealed cases.

Consistent case feed is ensured whether spaced or continuous. The pacer belt infeed separates and spaces the cases precisely for flap closing and sealing.

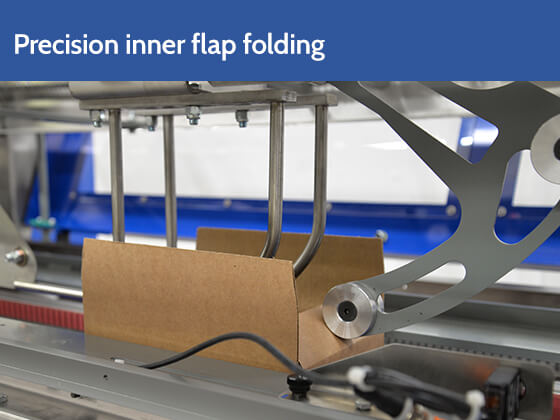

Inner flaps are closed by either a reciprocating or rotary tucker, depending on the speed and application. The robust mechanisms precisely break the scores and positively fold the inner flaps to facilitate outer flap closing.

High traction, bottom belt drive provides positive transport and control. All cases are precisely indexed through flap closing and sealing.

Outer flaps are guided closed by contoured folders while a squaring bar eliminates flap overlap. This design is proven to deliver square cases for stable palletloads.

Case flaps are compressed by flexible rollers to secure the hot melt bond. The rollers accommodate case height variations to ensure a secure seal on every case.