A-B-C Blog

Full height display cases: A retail ready packaging solution

Considering retail ready packaging? Display cases offer a simple and economical solution.

Retail ready packaging (RRP) is on the mind of most packaged goods companies today. In some cases, it is a requirement for distribution in large retailers and big box stores. Yet RRP can also offer sustainability rewards in reduced material consumption.

What is retail ready packaging?

In the simplest sense, it is packaging that arrives at the end user ready for display. No corrugated cutters, no unloading individual items, no arranging products on shelves. The product is placed on the shelf right in the shipper, saving time and making restocking more efficient. In addition, retail ready packaging makes it easy for the consumer to identify your brand, select an item, and leave the remainder intact ready for the next person’s selection.

Making the transition to RRP

First and foremost, it is important that your product is shipped safely and damage-free from your plant to the end user. There are many different product variables and packaging options to consider, including perforated wraparound cases, 2-part trays, trays with top pads and shrink-wrap, and more.

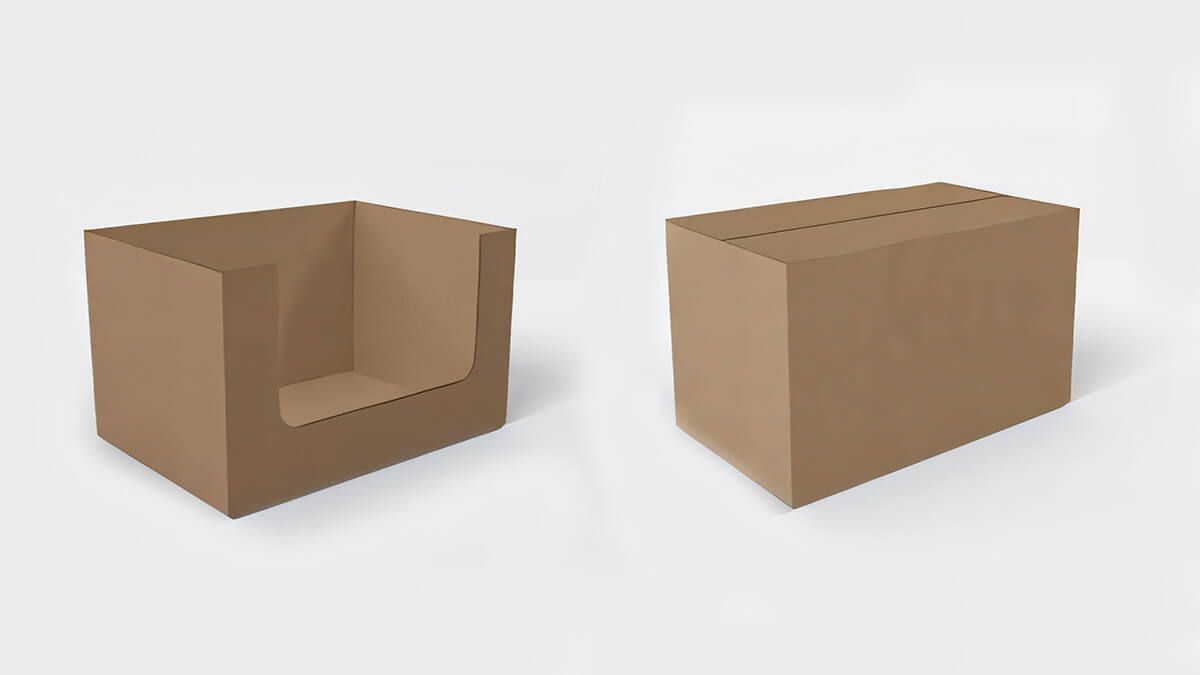

Full height display cases combine economy and flexibility

Full height display cases combine full product visibility and primary package protection. They can be shrink-wrapped or not, depending on the primary product requirements. At the retail level, they provide both stocking convenience and broad on-shelf visibility for the primary package. Yet possibly the greatest advantage is the low cost of conversion to display cases utilizing your existing downstream production equipment and an A-B-C case erector.

A-B-C erectors are designed from infeed, through opening, and sealing, to run RSC cases, HSC cases, and display cases interchangeably. No change parts are required; only dimensional adjustments if the display case size is different than your other case sizes. Therefore, an A-B-C case erector can eliminate the need for a line reconfiguration requiring major capital equipment expenditures while meeting most retailers’ display requirements.

Here’s how our unique machine design accommodates display cases:

- Top of stack KD feed with dual grippers and slidebar accommodates case cutouts- no tension is required for KD feed

- Case is opened on the major bottom flap–not the sidewall

- Cases are squared by the walking beam transfer through adhesive or tape application

- Display cases are squared during tape application or adhesive compression, forming square and secure cases for smooth packing and palletizing

Whether you need the flexibility to make RSC cases and display cases to meet retail requirements, or need to run only display cases, your A-B-C erector can supply your needs, and reduce your corrugated consumption by up to 30% with strong, secure packaging that will protect your product during transport and display it proudly at the end user.

View the video to see display case and RSC erector operation

We’d be happy to discuss your requirements and options, as well as other retail ready solutions.

Call 800-237-5975 or send your specifications and goals to receive a quote at the link below.