A-B-C Blog

Depalletizer ends bottlenecks

Watch and learn how A-B-C depalletizers are designed for top production

Four exclusive features to ensure top container stability

Even shrinkwrapped pallets can shift in transport or unwrapping-so it's critical to square the layers before depalletizing. We square both the primary and secondary layers before bottles are moved, to ensure stability.

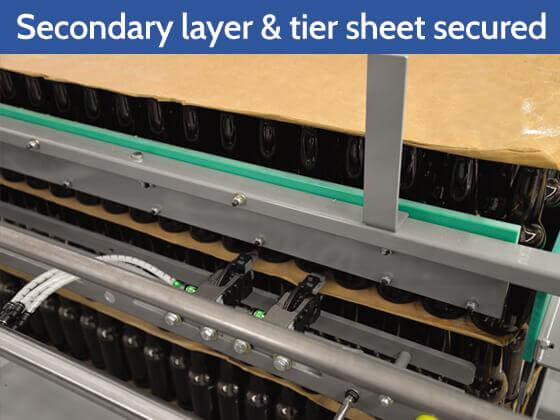

As the primary layer is swept from the pallet, the secondary layer is secured on all four sides by steel friction plates. Below, multiple grippers hold the tier sheet securely in place.

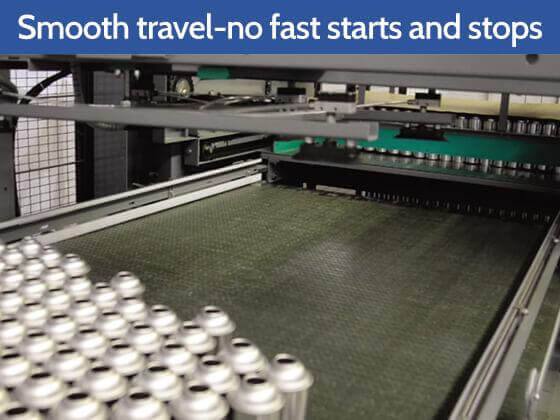

The elevator table is powered by a variable speed motor that delivers efficient and gentle transport. The table is guided by 8-point location roller bearings and counter-weighted to ensure reliable vertical operation.

Sweep gap is a common culprit in downed containers, so we eliminate it - using a motorized support bar that travels with the bottles and prevents friction from causing instability.